-

Posts

619 -

Joined

-

Last visited

-

Days Won

22

Content Type

Profiles

Forums

Gallery

Everything posted by Wubster100

-

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

@Haz Can you post information from the 2019+ Ford Edge China 3 row / 7 seat? Specifically information about the side mirrors and cameras. -

Park lamps

Wubster100 replied to Mustache's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

Welcome to the forum @Mustache, Attached is a wiring diagram for the turn signal lamps. Have you checked the lamp holder to ensure that the bulb has a good connection? Can you measure parking lamp voltage at the lamp holder? Turn Signal-Stop-Hazard Lamps Wiring Diagram 1 - 2009 Edge Workshop Manual.pdf -

Did you install all of these items yourself? Does the securicode stick on to the vehicle, or is in embedded into the door pillar? How do all of your LED ambient lights look?

-

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

Nevermind, the information needed is already posted above. -

Tail Light Moisture Condensation 2019-2024

Wubster100 replied to Wubster100's topic in 2019-Current Edge & Nautilius

I looked at mine, and they don't seem like holes. -

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

@Haz Can you post the connector pin out of the front controls for the 2021-2024 Edge? It is the one that connects to the airbag light indicator, camera button, hazard lights button, max defrost button, volume and tune knob, etc. Also curious to see what module these buttons are connected to. -

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

Next steps are to permanently install the IPMB, get shielded wire, and install 4 new cameras. -

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

-

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

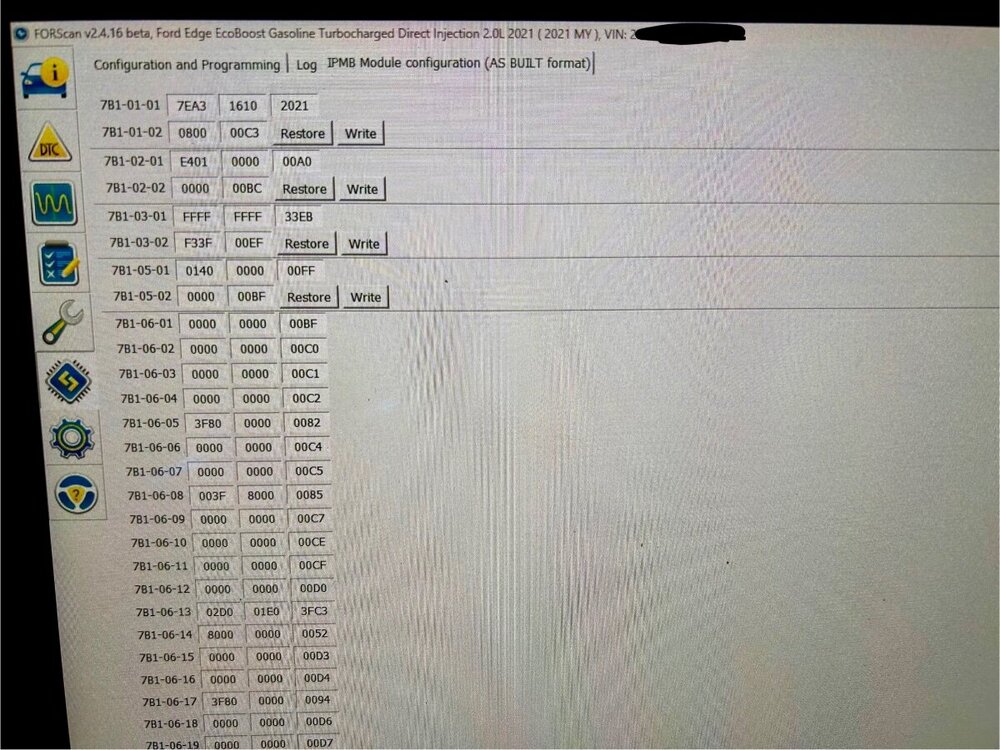

THE IPMB ACTUALLY WORKS!!!!!!!! -

Ford constantly has errors in the owners manuals and other documents.

-

I see a horn relay and a 20 amp fuse in both the 2020 and 2024 wiring diagrams.

-

Retrofit 360 Camera Into Ford Edge

Wubster100 replied to Wubster100's topic in Accessories & Modifications

Hello everyone, An update to my progress. I was able to take the BCM connector apart for the rear camera LIN circuit. I added a loop of wire to it, so that I can easily connect to the LIN circuit it in the future. I connected power and CAN bus to the new IPMB using the HCM connection, and it works. The new IPMB is able to be seen in FORScan. My next steps will be to remove the touchscreen display to get access to the APIM connector. Then, I can connect my rear camera to the IPMB and test. -

Tail Light Moisture Condensation 2019-2024

Wubster100 replied to Wubster100's topic in 2019-Current Edge & Nautilius

I will have to check and see if I have those. -

From the VIN number, the vehicle is not equipped with the factory tow package. There is no trailer sway control.

-

The traction control button does not turn off AWD. The AWD system is fully automatic, and most of the time power is sent to the front wheels only. There is no real way to turn AWD off (except for maybe pulling the AWD fuse lol). All Wheel Drive The AWD system is an active system, which means it not only responds to wheel slip between the front and rear axles but also has the ability to anticipate wheel slip and transfer torque to the rear wheels before the slip occurs. The AWD system is active all the time and requires no input from the operator. The AWD system continuously monitors vehicle conditions and automatically adjusts the torque distribution between the front and rear wheels. During normal operation, most of the torque is delivered to the front wheels. If different wheel speeds (slip) between the front and rear wheels is is detected, the vehicle is under heavy acceleration or if the vehicle is in a handling event, the AWD system increases the duty cycle to the RDU Coupling motor. The RDU Coupling motor commences an RDU clutch activation, in the Rear Drive Unit (RDU) which in turn sets a ball ramp device in motion. The ball ramp device applies the main clutch pack in the RDU and increases torque to the rear wheels as necessary. When the AWD system is functioning properly, there should be no perceived speed difference between the front and rear axles when launching or driving the vehicle on any uniform surface. Traction should be similar to a part time 4WD system operating in 4H (4X4 HIGH), but have no binding in turns. AdvanceTrac The AdvanceTrac system is comprised of the traction control and ESC features. Traction Control The ABS module continuously monitors and compares the rotational speed of the drive wheels in relation to the non-driven wheels. When the drive wheels begin to spin faster than the non-driven wheels, the ABS module modulates brake pressure to the appropriate brake caliper(s) by opening and closing the appropriate solenoid valves inside the HCU while the hydraulic pump motor is activated. At the same time, the ABS module calculates how much engine torque reduction is required to eliminate the wheel slip and sends this torque reduction message along with a traction event message to the GWM over the HS-CAN2. The GWM sends the engine torque reduction message to the PCM over the HS-CAN1 and the traction event message to the IPC over the HS-CAN3. When the PCM receives the torque reduction message, it adjusts engine timing and decreases fuel injector pulses to reduce the engine torque to the requested level. When the IPC receives the traction event message it flashes the stability-traction control indicator (sliding car icon). Once the driven wheel speed returns to the desired speed, the ABS module returns the solenoid valves in the HCU to their normal position, deactivates the hydraulic pump motor and stops sending the traction event and torque reduction messages. The PCM returns engine timing and fuel injectors to normal operation and the IPC extinguishes the stability-traction control indicator (sliding car icon). After the vehicle speed exceeds 100 km/h (62 mph), traction control is accomplished only through the PCM torque control. Traction control can be disabled using the traction control switch in the following manner: Momentarily pressing the switch disables only traction control, ABS, ESC and RSC remain enabled. Pressing the switch twice rapidly engages Sport Mode. Sport mode modifies the stability control intervention thresholds to allow for a more driving experience. Pressing the switch once after the system is deactivated fully enables the traction control system. Pressing the switch once after Sport mode is activated, deactivates Sport mode and fully enables the traction control system. When the driver disables traction control, the IPC communicates traction control status to the GWM along the HS-CAN2. The GWM sends the message to the ABS module along the HS-CAN2. The ABS module takes no further action in regards to traction control until the driver activates the function or until the ignition is cycled from OFF to ON. Traction control is disabled if there is a wheel speed sensor or solenoid valve DTC present in the ABS module. Traction control is also disabled if there is a communication error between the ABS module and the GWM. When traction control is disabled, the ABS module sends a message to the GWM along the HS-CAN2 which gateways the message to the IPC over the HS-CAN3 to illuminate the stability-traction control OFF indicator (sliding car OFF icon). Electronic Stability Control (ESC) The ABS module continuously monitors the vehicle motion relative to the intended course. This is done by using sensors to compare the steering wheel sensor messages, yaw rate sensor messages and longitudinal acceleration with the actual vehicle motion. On vehicles without active park assist, steering angle information is calculated by the PSCM and sent to the ABS module over the HS-CAN2. On vehicles with active park assist, steering angle information is sent by the SCCM over the HS-CAN2. Vehicle yaw rate and longitudinal acceleration information is sent to the ABS module from the RCM over the HS-CAN2. If the ABS module determines from the inputs the vehicle is unable to travel in the intended direction, the brake pressure to the appropriate brake caliper(s) is modulated by opening and closing the appropriate solenoid valves inside the HCU while the hydraulic pump motor is activated. At the same time the ABS module calculates how much engine torque reduction is required to reduce vehicle speed to help stabilize the vehicle and sends this torque reduction message, along with an ESC event message, to the GWM over the HSCAN2. The GWM sends the torque reduction message to the PCM over the HS-CAN1 and the ESC event message to the IPC over the HSCAN3. When the PCM receives the torque reduction message, it adjusts engine timing and decreases fuel injector pulses to reduce the engine torque to the requested level. When the IPC receives this message, it flashes the stability-traction control indicator (sliding car icon). Once the vehicle instability has been corrected, the ABS module returns the solenoid valves in the HCU to their normal position, deactivates the hydraulic pump motor and stops sending the ESC event and torque reduction messages. The PCM returns engine timing and fuel injectors to normal operation and the IPC extinguishes the stability-traction control indicator (sliding car icon). ESC does not operate with the transmission in REVERSE. ESC is disabled if there is a wheel speed sensor, stability sensor or steering angle sensor DTC present in the ABS module. ESC is also disabled if there is a communication error between the ABS module and the PSCM, the ABS module and the RCM or the ABS module and the SCCM (if equipped). When ESC is disabled, the ABS module sends a message to the GWM along the HS-CAN2 which gateways the message to the IPC over the along the HS-CAN3 to illuminate the stability-traction control OFF indicator (sliding car OFF icon). Roll Stability Control (RSC) The ABS module continuously monitors the vehicle motion relative to the intended course. This is done by using sensors to compare the steering wheel sensor messages, yaw rate sensor messages, lateral acceleration sensor messages, longitudinal acceleration sensor messages and roll rate sensor messages with the actual vehicle motion. On vehicles without active park assist, steering angle information is calculated by the PSCM and sent to the ABS module over the HS-CAN2. On vehicles with active park assist, steering angle information is sent by the SCCM over the HSCAN2. Vehicle yaw rate, lateral acceleration, longitudinal acceleration and roll rate information is sent to the ABS module from the RCM over the HS-CAN2. If the ABS module determines from the inputs the vehicle is becoming unstable, the brake pressure to the appropriate brake caliper(s) is modulated by opening and closing the appropriate solenoid valves inside the HCU while the hydraulic pump motor is activated. At the same time the ABS module calculates how much engine torque reduction is required to help stabilize the vehicle and sends this torque reduction message, along with an RSC event message, to the GWM over the HS-CAN2. The GWM sends the torque reduction message to the PCM over the HSCAN1 and the RSC event message to the IPC over the HS-CAN3. When the PCM receives the torque reduction message, it adjusts engine timing and decreases fuel injector pulses to reduce the engine torque to the requested level. When the IPC receives this message, it flashes the stability-traction control indicator (sliding car icon). Once the vehicle instability has been corrected, the ABS module returns the solenoid valves in the HCU to their normal position, deactivates the hydraulic pump motor and stops sending the RSC event and torque reduction messages. The PCM returns engine timing and fuel injectors to normal operation and the IPC extinguishes the stability-traction control indicator (sliding car icon). RSC does not operate with the transmission in REVERSE. RSC is disabled if there is a wheel speed sensor, stability sensor or steering angle sensor DTC present in the ABS module. RSC is also disabled if there is a communication error between the ABS module and the PSCM, the ABS module and the RCM or the ABS module and the SCCM (if equipped). When RSC is disabled, the ABS module sends a message to the GWM along the HS-CAN2 which gateways the message to the IPC over the along the HS-CAN3 to illuminate the stability-traction control OFF indicator (sliding car OFF icon). Trailer Sway Control Trailer sway is the undesirable yaw force a trailer can apply to the towing vehicle. Trailer sway control is a unique function of the stability control system that uses steering wheel angle information and yaw rate information to determine if a trailer sway event is taking place. On vehicles without active park assist, steering angle information is calculated by the PSCM and sent to the ABS module over the HS-CAN2. On vehicles with active park assist, steering angle information is sent by the SCCM over the HS-CAN2. Vehicle yaw rate information is sent to the ABS module from the RCM over the HS-CAN2. If the ABS module determines from the inputs a trailer sway event is taking place, the ABS module modulates brake pressure to the appropriate brake calipers by opening and closing the appropriate solenoid valves inside the HCU while the hydraulic pump motor is activated. At the same time, the ABS module calculates how much engine torque reduction is required to eliminate the trailer sway and sends this torque reduction message to the GWM over the HS-CAN2 which relays the message to the PCM over the HS-CAN1. The ABS module also sends a trailer sway event message to the GWM over the HS-CAN2 which relays this message to the IPC over the HS-CAN3. When the PCM receives the torque reduction message, it adjusts engine timing and decreases fuel injector pulses to reduce the engine torque to the requested level. When the IPC receives the vehicle stability event message, it flashes the stability-traction control indicator (sliding car icon) and displays TRAILER SWAY REDUCE SPEED in the message center. Once the trailer sway has been corrected, the ABS module returns the solenoid valves in the HCU to their normal position, deactivates the hydraulic pump motor and stops sending the traction event and torque reduction messages. The PCM returns engine timing and fuel injectors to normal operation and the IPC extinguishes the stability-traction control indicator (sliding car icon) and stops displaying the trailer sway message in the message center. Trailer sway control only activates when vehicle speed is greater than 65 km/h (40 mph). Any malfunction disabling RSC also disables trailer sway control. The driver can enable and disable the trailer sway control feature using the message center and steering wheel controls. For additional information, refer to the Owner's Literature. Curve Control The ABS module continuously monitors the vehicle motion relative to the intended course. This is done by using sensors to compare the steering wheel input, the yaw rate sensor input, the lateral acceleration sensor input and the longitudinal acceleration sensor input with the actual vehicle motion. On vehicles without active park assist, steering angle information is calculated by the PSCM and sent to the ABS module over the HSCAN2. On vehicles with active park assist, steering angle information is sent by the SCCM over the HS-CAN2. Vehicle yaw rate, lateral acceleration and longitudinal acceleration information is sent to the ABS module from the RCM over the HS-CAN2. If the ABS module determines from the inputs the vehicle is experiencing over-steer or under-steer while traveling through a curve, the module sends a curve control event message over the HS-CAN2 to the GWM. The GWM relays this message to the PCM over the HS-CAN1 and to the IPC over the HSCAN3. When the PCM receives this message, it assists with curve control by adjusting engine timing and decreasing fuel injector pulses. When the IPC receives this message, it flashes the stability-traction control indicator (sliding car icon). The ABS module continues to monitor the sensor inputs while the PCM assists with curve control. If the ABS module determines PCM intervention is insufficient to control the stability event, the ABS module modulates brake pressure to the appropriate brake caliper(s) by opening and closing the appropriate solenoid valves inside the HCU while the hydraulic pump motor is activated. Once the vehicle instability has been corrected, the ABS module returns the solenoid valves in the HCU to their normal position, deactivates the hydraulic pump motor and stops sending the curve control event message. The PCM returns engine timing and fuel injectors to normal operation and the IPC extinguishes the stability-traction control indicator (sliding car icon). The curve control system does not operate with the transmission in REVERSE. The ABS module disables the curve control system if there are any wheel speed sensor, stability sensor or steering angle sensor Diagnostic Trouble Codes (DTCs) present in the ABS module. The curve control system is also disabled if there is a communication error between the ABS module and the PSCM, the ABS module and the RCM or the ABS module and the SCCM (if equipped). When the curve control system is disabled, the ABS module sends a message over the HS-CAN2 to the GWM. The GWM relays this message over the HS-CAN3 to the IPC to illuminate both the stability-traction control indicator (sliding car icon) and the stability-traction control disabled indicator (sliding car OFF icon).

-

It seems like there are some problems with the AsBuilt data. Are you located in North America or Europe? 7D0-01-01: xxxx-*xxx-xxxx 4=Aux Audio Only, C1MCA EU Climate Strategy, Chimes NA Strategy, Rotary Volume 0=Aux Audio Only, CGEA NA Climate Strategy, Chimes NA Strategy, Rotary Volume 7D0-01-01: xxxx-xxxx-*xxx E=ICAND On, Smart Auto Enabled, My Temp Available, Non RDS Market (NA) 0=ICAND Off, Smart Auto Disabled, My Temp Not Available, Non RDS Market (NA) 7D0-01-02: xxxx-xxxx-*xxx A=CGEA 1.3, Heated Windshield Disabled, Rear Climate Automatic 0=CGEA 1.2 or C1MCA, Heated Windshield Disabled, Rear Climate Manual w/o Air Flow Mode 8=CGEA 1.3, Heated Windshield Disabled, Rear Climate Manual w/o Air Flow

-

The OTA updates will apply to the SYNC 3 system only. The newest SYNC 3 version should be v3.4.22251. From the photos, you are on v3.4.21194. If you still can’t figure it out, then message me the VIN number and I can check.

-

-

Welcome to the forum @DavidD, The horn is located underneath the driver's side headlight.

-

The BMS reset is reserved for only when replacing the battery.