Haz

Edge Member-

Posts

1,510 -

Joined

-

Last visited

-

Days Won

405

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

-

Welcome to the Forum, danwdc ! The following sections from the 2013 Edge Workshop Manual describe the components and operation of the Adaptive Cruise Control & Forward Collision Warning systems, as well as provide extensive diagnostic procedures guided by Diagnostic Trouble Codes (DTCs) and using Parameter Identifiers (PIDs), in most cases. If your efforts progress to applying specific Pinpoint Test routines requiring wiring diagrams and electrical connector circuit details and locations, I can provide you those informational resources. Document download links> Cruise Control — Adaptive - Description and Operation - 2013 Edge-MKX Workshop Manual.pdf Cruise-Control Module (C-CM) - Removal and Installation - 2013 Edge-MKX Workshop Manual.pdf Cruise Control Module (C-CM) (with Sensor) Adjustment - General Procedures - 2013 Edge-MKX Workshop Manual.pdf Cruise Control - Diagnosis and Testing - 2013 Edge-MKX Workshop Manual.pdf Forward Collision Warning - Description and Operation - 2013 Edge-MKX Workshop Manual.pdf Forward Collision Warning - Diagnosis and Testing - 2013 Edge-MKX Workshop Manual.pdf For comparison to your 2013 Edge's left-side Information Screen, the following photos show the menu structure in our similarly equipped (and also GEN 1+) 2015 MKX... After Normal is selected, the following Warning Message appears, accompanied by a Warning Chime... Good luck!

-

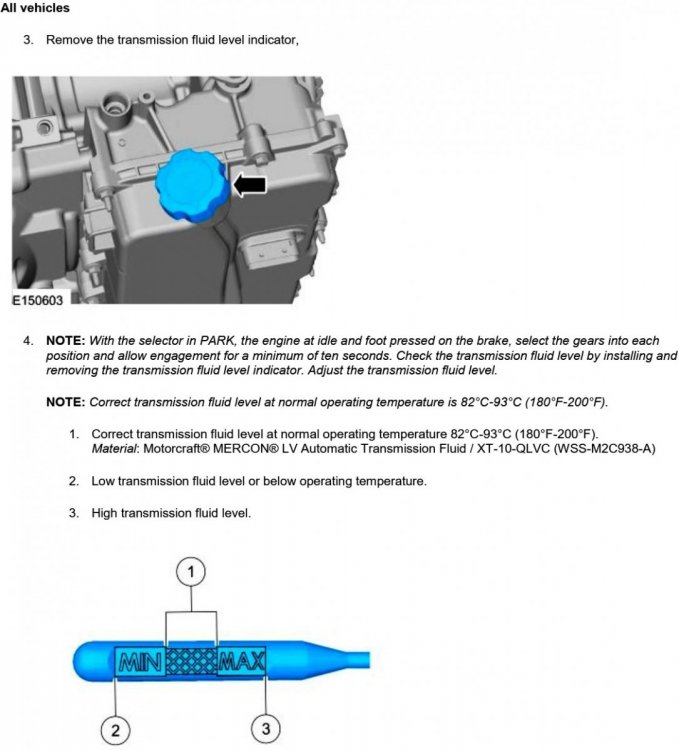

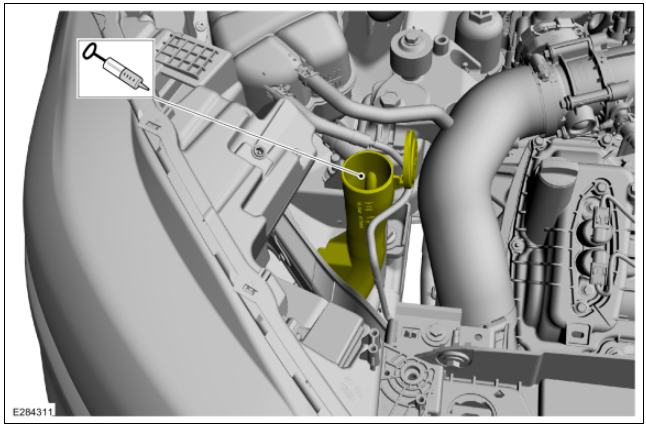

From the 2016 Edge Workshop Manual, relating to the 6F50 6-Speed Auto Trans paired with the 3.5L Duratec (or the 6F55 paired with the 2.7L EcoBoost)... NOTE: If the transmission was removed and disassembled, fill the transmission with 6.2L (6.5 qt) of clean transmission fluid. If the main control cover was removed, fill the transmission with 4.3L (4.5 qt) of clean transmission fluid. Material: Motorcraft® MERCON® LV Automatic Transmission Fluid / XT-10-QLVC (WSS-M2C938-A) Document download links> Transmission Fluid Drain and Refill - 6F50-6F55 6-Speed Auto Trans - 2016 Edge Workshop Manual.pdf Transmission Fluid Level Check - 6F50-6F55 6-Speed Auto Trans - 2016 Edge Workshop Manual.pdf Good luck!

-

The following sections from the 2016 Edge Workshop Manual describe the components and operation of the AWD system, as well as provide extensive diagnostic procedures guided by Diagnostic Trouble Codes (DTCs), in most cases. If your efforts progress to applying specific Pinpoint Test routines requiring wiring diagrams and electrical connector circuit details and locations, I can provide you those informational resources. Document download links> Four-Wheel Drive Systems - System Operation and Component Description - 2016 Edge Workshop Manual.pdf Transfer Case 3.5L Duratec - Power Transfer Unit (PTU) Overview - 2016 Edge Workshop Manual.pdf Transfer Case 3.5L Duratec - Transfer Case Cooler - Removal and Installation - 2016 Edge Workshop Manual.pdf Transfer Case - Diagnosis and Testing - 2016 Edge Workshop Manual.pdf Four-Wheel Drive Systems - Active Torque Coupling Configuration - 2016 Edge Workshop Manual.pdf Four-Wheel Drive Systems - Diagnosis and Testing - 2016 Edge Workshop Manual.pdf All Wheel Drive (AWD) Module - Removal and Installation - 2016 Edge Workshop Manual.pdf Good luck!

-

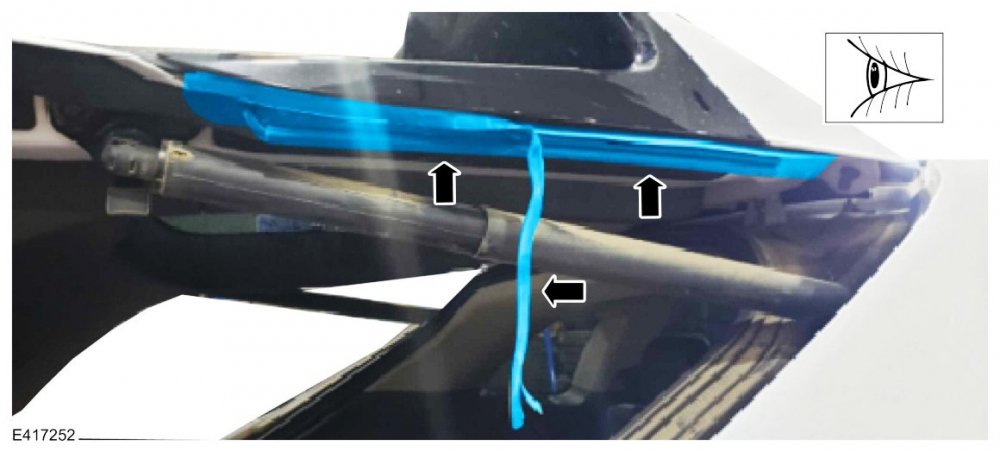

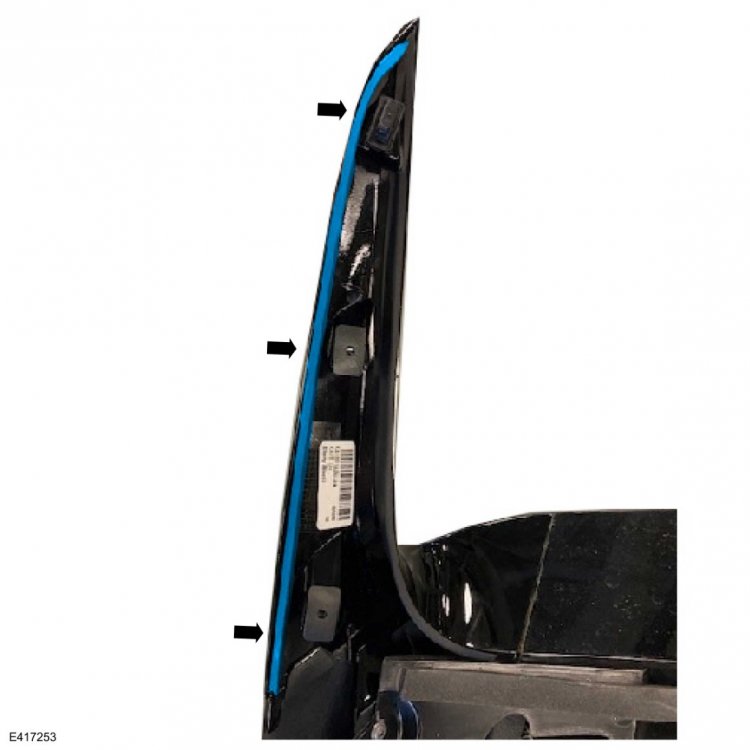

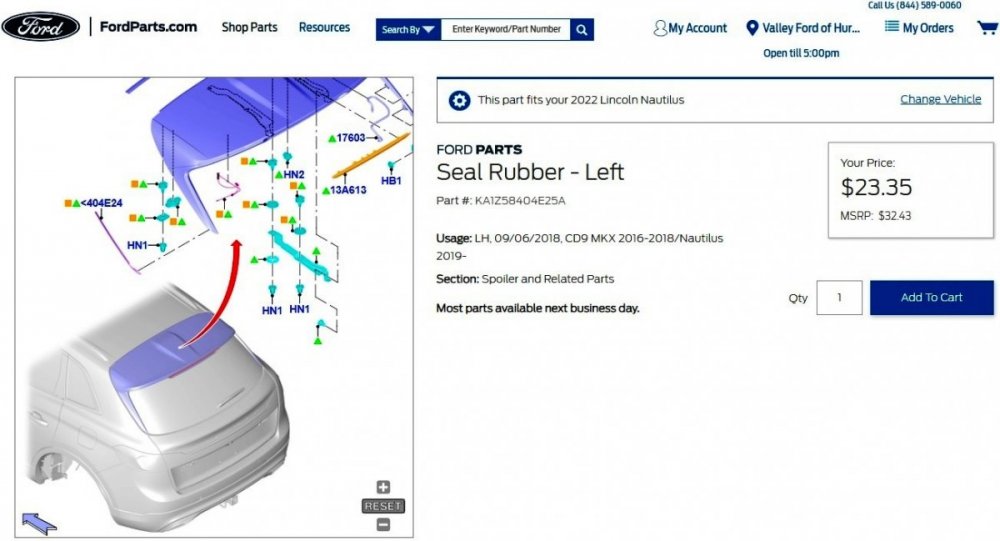

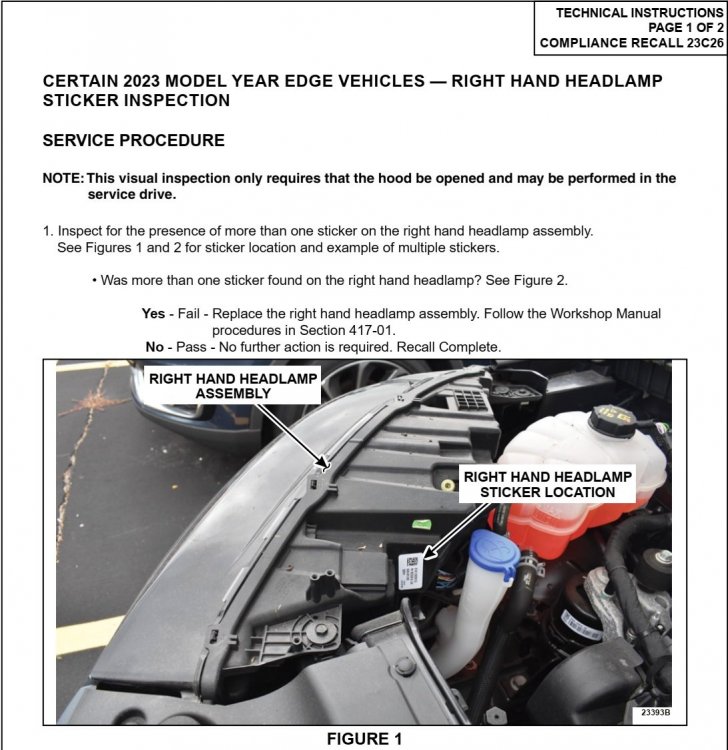

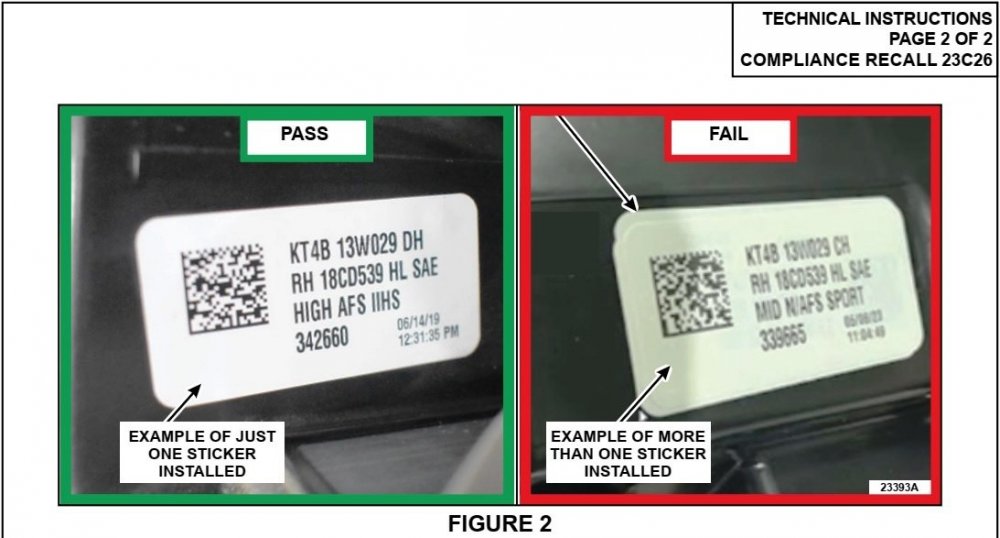

TECHNICAL SERVICE BULLETIN Rubber Seal Loose Between Spoiler Support And Liftgate 23-2237 27 September 2023 Model: Lincoln 2019-2022 Nautilus Issue: Some 2019-2022 Nautilus vehicles may exhibit the rubber seal between the spoiler support and the liftgate coming loose as shown in Figure 1. This may be due to poor adhesion between the spoiler and the rubber seal. To correct the condition, follow the Service Procedure to replace spoiler support rubber seal. Action: Follow the Service Procedure to correct the condition on vehicles that meet the following criteria: • 2019-2022 Nautilus • Loose rubber seal between the spoiler support and the liftgate as shown in Figure 1 Parts Service Part Number Quantity Description Unit of Issue Piece Quantity KA1Z-58404E24-A 1 Right Rubber Seal 1 1 KA1Z-58404E25-A 1 Left Rubber Seal 1 1 Obtain Locally As Needed Isopropyl Alcohol Quantity refers to the amount of the service part number required to repair the vehicle. Unit of Issue refers to the number of individual pieces included in a service part number package. Piece Quantity refers to the total number of individual pieces required to repair the vehicle. As Needed indicates the amount of the part may vary and/or is not a whole number. Parts can be billed out as non-whole numbers, including less than 1. Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Service Part Warranty (SPW)/Special Service Part (SSP)/Extended Service Plan (ESP) coverage. Limits/policies/prior approvals are not altered by a TSB. NVLW/SPW/SSP/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. Labor Times Description Operation No. Time 2019-2022 Nautilus: Replace The Spoiler Support Rubber Seal (Do Not Use With Any Other Labor Operations) 232237A 0.9 Hrs. Repair/Claim Coding Causal Part: 5844210 Condition Code: 33 Service Procedure Figure 1 1. Remove the spoiler. Refer to Workshop Manual (WSM), Section 501-08 - Exterior Trim and Ornamentation - Removal and Installation - Rear Spoiler. 2. Remove the loose spoiler support rubber seal. (Figure 2) Figure 2 3. Clean the surface with isopropyl alcohol. 4. Align and attach the new rubber seal. 5. Install the spoiler. Refer to WSM, Section 501-08 - Exterior Trim and Ornamentation - Removal and Installation - Rear Spoiler. © 2023 Ford Motor Company All rights reserved. NOTE: The information in Technical Service Bulletins is intended for use by trained, professional technicians with the knowledge, tools, and equipment to do the job properly and safely. It informs these technicians of conditions that may occur on some vehicles, or provides information that could assist in proper vehicle service. The procedures should not be performed by "do-it-yourselfers". Do not assume that a condition described affects your car or truck. Contact a Ford or Lincoln dealership to determine whether the Bulletin applies to your vehicle. Warranty Policy and Extended Service Plan documentation determine Warranty and/or Extended Service Plan coverage unless stated otherwise in the TSB article. The information in this Technical Service Bulletin (TSB) was current at the time of printing. Ford Motor Company reserves the right to supersede this information with updates. The most recent information is available through Ford Motor Company's on-line technical resources. Document download links to resources mentioned in TSB 23-2237> TSB 23-2237 - 2019-2022 Nautilus - Rubber Seal Loose Between Spoiler Support And Liftgate - 09-27-2023.pdf TSB 23-2237 - 2019-2022 Nautilus - Enhanced Image - Figure 1.pdf TSB 23-2237 - 2019-2022 Nautilus - Enhanced Image - Figure 2.pdf Rear Spoiler - Removal and Installation - 2022 Nautilus Workshop Manual.pdf Link to this page from Ford's online parts website Link to this page from Ford's online parts website

-

2007-2015 Edge, MKX low brake pedal simple fix

Haz replied to enigma-2's topic in Brakes, Chassis & Suspension

Additional info from the Edge Workshop Manual, with emphasis added... Brake Master Cylinder Compensator Ports The purpose of the compensator ports in the brake master cylinder is to supply additional brake fluid from the master cylinder reservoir when needed by the brake system due to brake lining wear and allow brake fluid to return to the master cylinder reservoir when the brakes are released. The returning brake fluid creates a slight turbulence in the master cylinder reservoir. This is a normal condition and indicates that the compensator ports are not clogged. Clogged compensator ports may cause the brakes to hang up or not fully release. Document download link> Brake System - Principles of Operation - 2014 Edge Workshop Manual.pdf Good luck! -

Power Folding Mirror Synchronization Video #2 Power Folding Mirror Synchronization Video #2.mp4

- 1 reply

-

- 1

-

-

Special Service Message 51937 - Various 2015-2023 Vehicles - Inoperative Or Clicking Sound From Power Folding Exterior Mirrors Some vehicles equipped with power folding mirrors may exhibit power folding mirrors that are inoperative or exhibit a clicking sound. This may be due to the mirrors being manually folded in, during transportation, going through a car wash, bumped in a parking lot, or found during pre-delivery inspection (PDI). Prior to the replacement of any components, attempt to synchronize the mirrors by following the Power Mirrors Synchronization procedure. Refer to Workshop Manual (WSM)Section 501-09 Rear View Mirrors - General Procedures - Power Mirrors Synchronization. Power Folding Mirror Synchronization Video #1 Power Folding Mirror Synchronization Video #1.mp4

- 1 reply

-

- 1

-

-

Windshield wiper fluid reveresed

Haz replied to BmbSqd's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

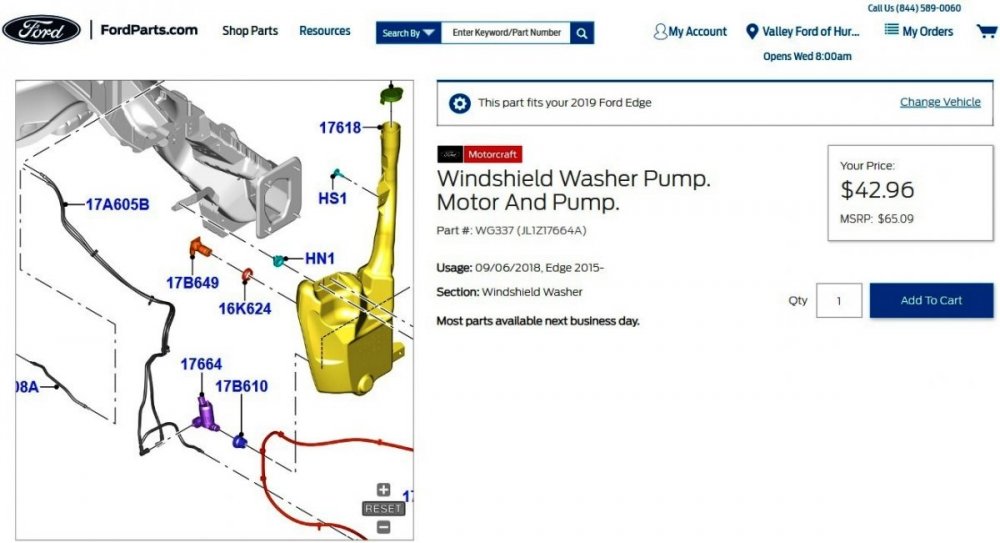

Additional document download links> WINDSHIELD WASHER PUMP - Wiring Diagram - 2019 Edge.pdf Rear Window Wiper Motor - Wiring Diagram - 2019 Edge.pdf Windshield Wiper Motors - Wiring Diagram - 2019 Edge.pdf Wiper Motors & Washer Pump - Power Distribution Wiring Diagram - 2019 Edge.pdf WINDSHIELD WASHER PUMP - Connector C137 Details - 2019 Edge.pdf WINDSHIELD WASHER PUMP - Connector C137 Location - 2019 Edge.pdf WINDSHIELD WIPER MOTOR LH - Connector C1665 Details - 2019 Edge.pdf Windshield Wiper Motor - Removal and Installation - 2019 Edge Workshop Manual.pdf Cowl Panel - Removal and Installation - 2019 Edge Workshop Manual.pdf Cowl Panel Grille - Removal and Installation - 2019 Edge Workshop Manual.pdf Windshield Wiper Pivot Arm - Removal and Installation - 2019 Edge Workshop Manual.pdf BATTERY JUNCTION BOX (BJB) - Connector C1035B Details - 2019 Edge.pdf BATTERY JUNCTION BOX (BJB) - Connector C1035B Location - 2019 Edge.pdf BATTERY JUNCTION BOX (BJB) Illustration- Shows Connector C1035B Receptacle Location - 2019 Edge.pdf Link to this FordParts web page Titanium Plus packaged Edges with the front camera washer use the following washer pump... Link to this FordParts web page The above FordParts web pages include numerous photos of the described washer pumps. Good luck!- 2 replies

-

- 1

-

-

- fluid

- windshield

-

(and 1 more)

Tagged with:

-

Windshield wiper fluid reveresed

Haz replied to BmbSqd's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

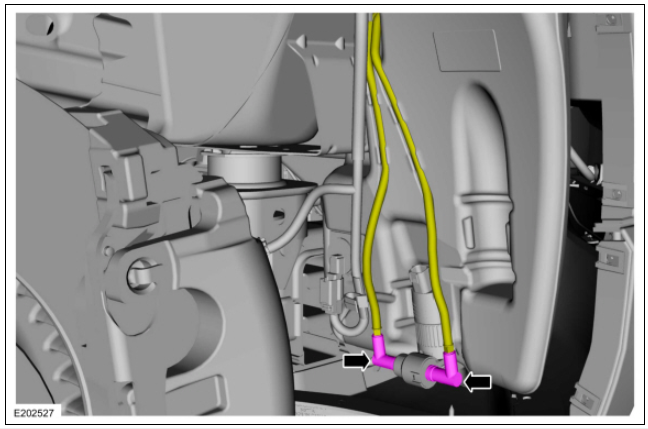

Welcome to the Forum, BmbSqd ! Your Edge's washer pump is attached to the lower portion of the washer fluid reservoir in the forward passenger side corner of the engine compartment... ghlighted You'll notice the two yellow-highlighted washer fluid hoses with their pink-highlighted couplings attached to the washer pump outlets. I expect one hose supplies the windshield nozzles and the other hose supplies the rear window nozzle, per these technical descriptions of front & rear washer operation from the 2019 Edge Workshop Manual... Windshield Washer When the wiper/washer switch is activated, the SCCM sends the washer request to the driver side windshield wiper motor assembly over the LIN . The windshield wash relay is internal to the driver side windshield wiper motor assembly. When the driver side windshield wiper motor assembly activates the internal windshield wash relay, voltage is provided to the washer pump, directing washer fluid to the windshield. If equipped with a front camera, washer solvent is also directed to the front camera lens when the washer pump is active. When the switch is released, the windshield wiper motors will continue to activate for 3 additional wipes and then turn off. Ground for the washer pump is provided through the rear window washer relay located within the BJB . Rear Window Washer When the rear window washer switch is activated, the SCCM sends the request to the driver side windshield wiper motor assembly through the LIN . The driver side windshield wiper motor assembly energizes the rear washer relay (located in the BJB ) and activates the rear window wiper motor. When the driver side windshield wiper motor assembly activates the rear window wash relay, voltage is provided to the washer pump, directing washer fluid to the rear window. When the switch is released, the rear window wiper motor continues to operate for 3 additional wipes and then turns off. Ground for the washer pump is provided through the windshield washer relay within the driver side windshield wiper motor assembly. Presuming the washer fluid hose couplings are not fool-proofed to only connect to the appropriate washer pump outlet for front or rear nozzle, then your swapping the hoses side-to-side may correct your Edge wrong-way spraying issue. Given that you've recently purchased the Edge, it seems unlikely a non-working washer pump was replaced and the wrong-way spray issue went unnoticed, though maybe it was a hurried job. It may be the result of a washer pump malfunction or a wiring/switch issue, but if swapping the hoses produces interim improvement, then it's worth a try. I've pulled relevant sections from the 2019 Edge Workshop and Wiring manuals, which will likely require two posts to provide due to Forum attachment size limitations. Document download links> Wipers and Washers - System Operation and Component Description - 2019 Edge Workshop Manual.pdf Windshield Washer Pump - Removal and Installation - 2019 Edge Workshop Manual.pdf Fender Splash Shield - Removal and Installation - 2019 Edge Workshop Manual.pdf Washer Hose Coupling - General Procedures - 2019 Edge Workshop Manual.pdf Windshield Washer Reservoir - Removal and Installation - 2019 Edge Workshop Manual.pdf Wipers and Washers - Diagnosis and Testing - 2019 Edge Workshop Manual.pdf- 2 replies

-

- 1

-

-

- fluid

- windshield

-

(and 1 more)

Tagged with:

-

- 1 reply

-

- 3

-

-

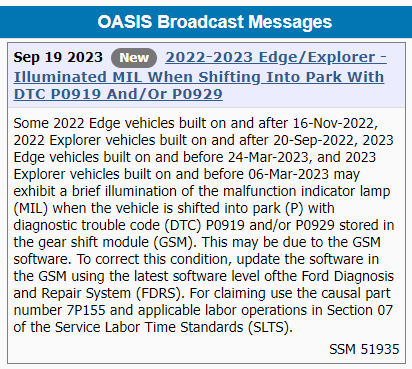

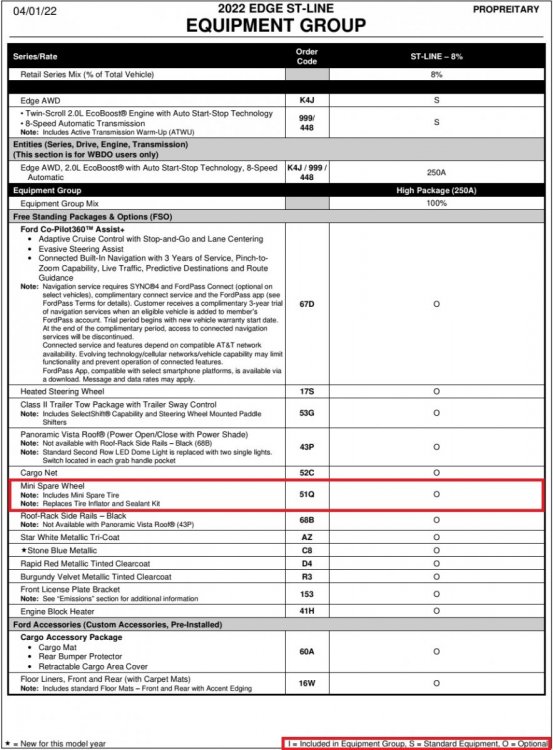

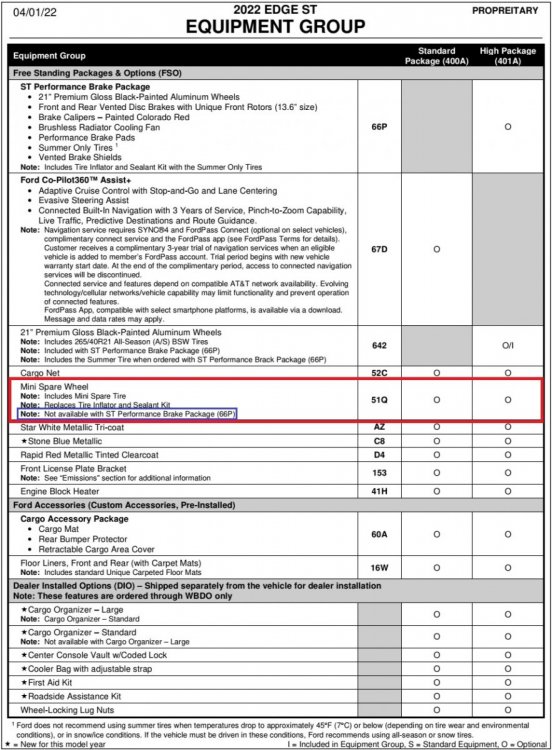

Welcome to the Forum, Gunner3.5 ! The 2022 Edge Order Guide shows the Mini Spare as optional equipment on the ST-Line... ...The Order Guide also shows the Mini Spare as optional on ST, but as Davidoo states, unavailable with the ST Performance Brake Package... Good luck!

-

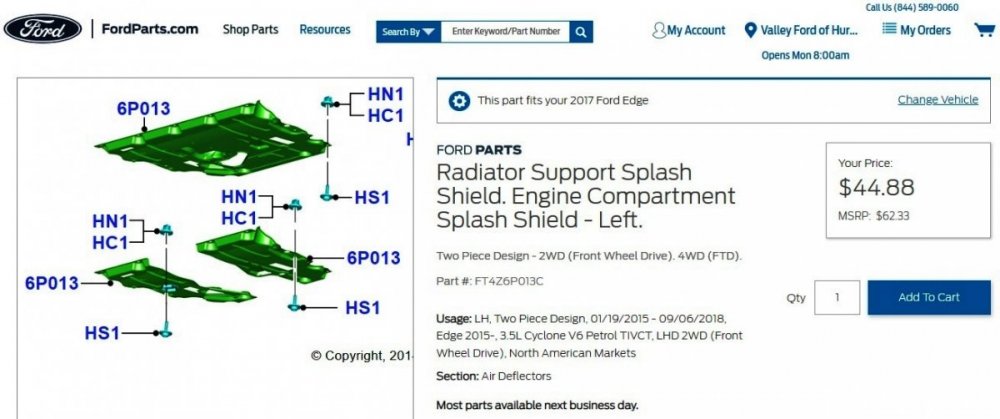

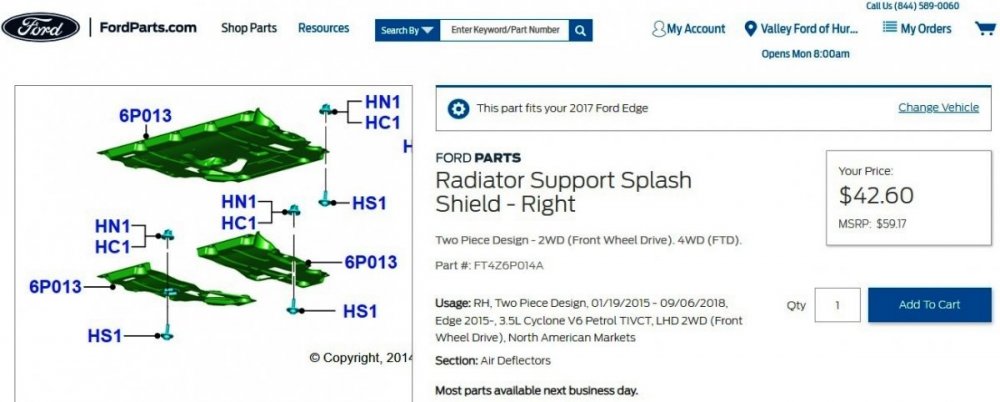

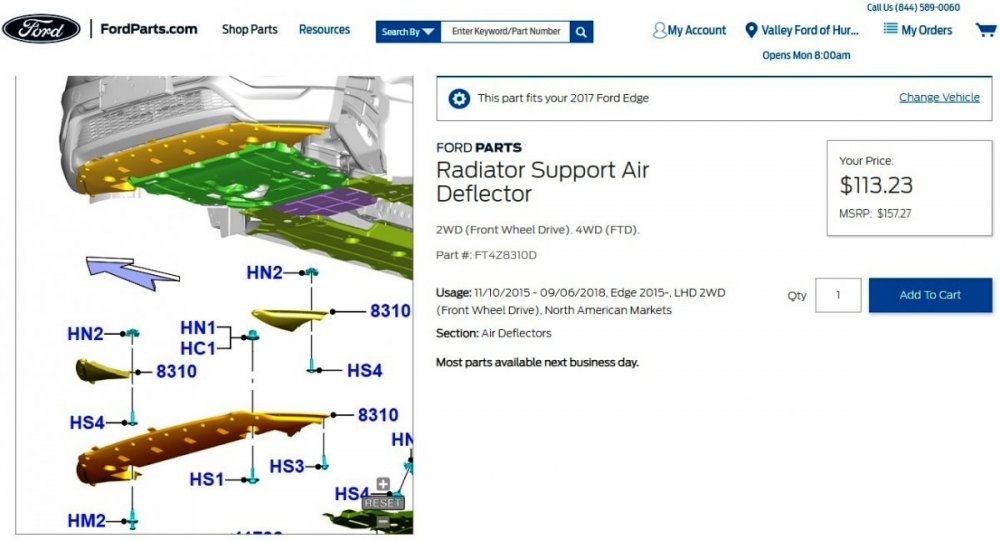

Splash shield for 2.0 interchangeable with 3.5L?

Haz replied to Oranga's topic in Brakes, Chassis & Suspension

Ford's online parts-selling site shows a 2-piece design Splash Shield for the 2017 3.5L Edge... Link to this web page Link to this web page ...Unless it is the Front Air Deflector you are seeking... Link to this web page The above-linked FordParts web pages include multiple photos of each described part. Good luck! -

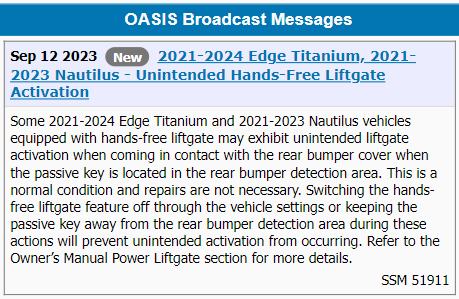

Ford is restating to the Service community that unintended hands-free liftgate operation is normal and no repair is needed to eliminate it, but that the solution for affected vehicle owners is deactivating the power liftgate or not having the passive key fob near the rear bumper when active in the cargo load space ... Good luck!

-

Omar: Yes, the procedure mentions scan-tool usage... Front Toe Adjustment - Vehicles With Active Steering - 2016 Edge Workshop Manual.pdf This causes me to wonder if the scan tool is being used to engage the Active Steering Wheel Lock to ensure the Steering Wheel is secured pointing straight ahead when the Front Toe Adjustment is made. A bit later today, I'll pull all the diagnostic Pinpoint Tests and edit into this post the full library of 2016 Edge Active Steering references. Good luck!

-

Document download links> Information and Entertainment System - Description and Operation- 2008 Edge-MKX Workshop Manual.pdf Module Configuration - Diagnosis and Testing - 2008 Edge-MKX Workshop Manual.pdf Audio Unit Part Number Retrieval - 2008 Edge-MKX Workshop Manual.pdf Instrument Panel Center Finish Panel - Removal and Installation - 2008 Edge-MKX Workshop Manual.pdf Instrument Panel Speaker - Removal and Installation - 2008 Edge-MKX Workshop Manual.pdf Audio Control Module (ACM) - Removal and Installation - 2008 Edge-MKX Workshop Manual.pdf Audio Control Module (ACM) - R & I Enhanced Image - 2008 Edge-MKX Workshop Manual.pdf Global Positioning System (GPS) Antenna - Removal and Installation - 2008 Edge-MKX Workshop Manual.pdf Audio System-Navigation - Wiring Diagram - 2008 Edge.pdf AUDIO CONTROL MODULE (ACM) - Connector C240A Details - 2008 Edge-MKX.pdf AUDIO CONTROL MODULE (ACM) - Connector C240B Details - 2008 Edge-MKX.pdf AUDIO CONTROL MODULE (ACM) - Connector C240C Details - 2008 Edge-MKX.pdf AUDIO CONTROL MODULE (ACM) - Connectors C240A, C240B, C240C Location - 2008 Edge-MKX.pdf Steering Wheel Controls - With SYNC & Navigation - Wiring Diagram - 2008 Edge-MKX.pdf Good luck!

-

-

2011 Edge Cooling Fans not running

Haz replied to atrdriver's topic in Interior, A.C., Heat, Interior Trim

Multi-model diagnostic procedure and Edge-specific supporting documents to address your Edge's cooling fan issue... Document download links> Pinpoint Test KN - Variable Speed Electric Cooling Fan - Powertrain Control-Emissions Diagnosis Manual.pdf COOLING FAN MODULE - Without Trailer Tow - Wiring Diagram - 2011 Edge Workshop Manual.pdf COOLING FAN MODULE - With Trailer Tow - Wiring Diagram - 2011 Edge Workshop Manual.pdf Battery Junction Box (BJB) - Illustration - 2011 Edge.pdf Battery Junction Box (BJB) - Fuse & Relay Listing - 2011 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Details - 2011 Edge.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Location - 2011 Edge.pdf COOLING FAN MODULE - Connector C1554 Details - 2011 Edge.pdf COOLING FAN MODULE - Connector C1554 Location - 2011 Edge Workshop Manual.pdf POWERTRAIN CONTROL MODULE (PCM) - Connector C175B Location - 2011 Edge.pdf Air Cleaner - Removal and Installation - 2011 Edge Workshop Manual.pdf Intake Air System Components - Exploded View Enhanced Image - 2011 Edge-MKX Workshop Manual.pdf Intake Air System Components - Exploded View - 2011 Edge-MKX Workshop Manual.pdf Cooling Fan and Shroud - Removal and Installation - 2011 Edge Workshop Manual.pdf Cooling Fan and Shroud - R&I Enhanced Image - 2011 Edge Workshop Manual.pdf Cooling Fan and Shroud - R&I Enhanced Connectors Illustration - 2011 Edge Workshop Manual.pdf Good luck! -

Good luck!

-

Welcome to the Forum, Remis ! Diagnostic information from the 2015 Edge Workshop Manual... The Manual Liftgate Latch Release Is Inoperative Normal Operations and Fault Conditions Liftgate Latch Release (manual liftgate) The liftgate latch can be released using: the exterior liftgate release switch. a valid programmed passive key. The BCM sends a voltage signal to the exterior liftgate release switch. When the liftgate release switch is pressed, the voltage signal is routed to ground, indicating a request to release the liftgate latch. The BCM momentarily provides voltage to the liftgate latch to actuate the release motor. When using the liftgate release switch, the BCM releases the liftgate only when the doors have been electronically unlocked and the vehicle is in PARK. When using a programmed RKE transmitter, press the liftgate release button twice within 3 seconds to release the liftgate latch. The liftgate latch releases if the vehicle speed is 5 km/h (3.1 mph) or less. The liftgate latch can also be released using the passive entry feature. Refer to Liftgate Passive Entry in this section. Passive Entry (if equipped) NOTE: To perform an accurate diagnosis of a concern, make sure the vehicle has a fully charged 12V battery and is in good condition when performing any electrical pinpoint tests. When the vehicle’s 12-volt battery is below a set threshold, certain features can be limited or become inoperative and lead to misdiagnosis. NOTE: Some models are not equipped with the passive entry feature, but are equipped with push button start. The passive entry feature unlocks or locks the doors or opens the liftgate without having to use a mechanical key blade or the RKE transmitter feature. When the BCM detects a lock or unlock sensor is touched on an exterior door handle, or the exterior liftgate release button is pressed, it activates the low frequency antenna in the corresponding exterior door handle or inside the luggage compartment area. The low frequency antenna sends out a signal to activate the passive key. The passive key then responds by sending a high frequency signal back to the RTM . The RTM interprets the high frequency signal from the passive key and sends the information to the BCM . If the BCM detects a valid programmed passive key, the BCM unlocks the driver door, unlocks or locks all 4 doors, releases the liftgate latch (manual liftgate) or sends a command to the RGTM to power open the liftgate (power liftgate). The passive entry (Intelligent Access) feature is part of vehicle load shed strategy. BCM DTC Fault Trigger Conditions DTC Description Fault Trigger Conditions B1219:11 Interior Boot/Trunk Release Switch: Circuit Short To Ground Sets when the BCM detects a short to ground from the exterior liftgate release switch input circuit. B12EE:11 Liftgate/Tailgate/Trunk Release: Circuit Short To Ground Sets when the BCM detects a short to ground from the liftgate latch release output circuit. B12EE:15 Liftgate/Tailgate/Trunk Release: Circuit Short To Battery or Open Sets when the BCM detects an open from the liftgate latch release output circuit. If the liftgate latch release is inoperative, GO to Pinpoint Test N If the liftgate does not latch, DISCONNECT the liftgate latch electrical connector and CHECK the operation of the latch using a screwdriver. If the latch does not fully latch (2 clicks), INSTALL a new liftgate latch. If the latch fully latches (2 clicks), REFER to the Wiring Diagrams manual to identify the possible cause of the circuit short in the liftgate latch release circuit. Possible Causes Wiring, terminals or connectors Liftgate release switch Liftgate latch BCM Visual Inspection and Diagnostic Pre-checks Inspect the liftgate release switch for damage. PINPOINT TEST N: THE MANUAL LIFTGATE LATCH RELEASE IS INOPERATIVE NOTE: This pinpoint test does not diagnose liftgate release concerns for vehicles with the power liftgate feature. Refer to Section 501-03 for power liftgate diagnostics. N1 CHECK THE LIFTGATE RELEASE INPUT FOR A SHORT TO GROUND USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition ON. Using a diagnostic scan tool, view the BCM Parameter Identifications (PIDs). Using a diagnostic scan tool, view the BCM PID LFTGATE_R_SW. Does the PID indicate the liftgate release switch is continuously pressed? Yes GO to N2 No GO to N4 N2 CHECK THE LIFTGATE RELEASE SWITCH USING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition OFF. Disconnect Liftgate Release Switch C4216. Ignition ON. Using a diagnostic scan tool, view the BCM PID LFTGATE_R_SW. Does the PID continue to indicate the switch is pressed? Yes GO to N3 No INSTALL a new liftgate release switch. REFER to: Liftgate Release Switch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). N3 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Disconnect BCM C2280D. Measure: Positive Lead Measurement / Action Negative Lead C4216 Pin 1 Ground Is the resistance greater than 10,000 ohms? Yes GO to N12 No REPAIR the circuit. N4 CHECK THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID while pressing the liftgate release switch. Does the PID indicate the switch is pressed? Yes GO to N8 No GO to N5 N5 BYPASS THE LIFTGATE RELEASE SWITCH WHILE MONITORING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Ignition OFF. Disconnect Liftgate Release Switch. Ignition ON. Connect: Lead 1 Measurement / Action Lead 2 C4216 Pin 1 C4216 Pin 2 Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID . Does the PID indicate the switch is pressed? Yes REMOVE the fused jumper wire. INSTALL a new liftgate release switch. REFER to: Liftgate Release Switch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). No REMOVE the fused jumper wire. GO to N6 N6 CHECK THE LIFTGATE RELEASE SWITCH GROUND CIRCUIT FOR AN OPEN WHILE MONITORING THE BCM (BODY CONTROL MODULE) LIFTGATE RELEASE SWITCH STATUS (LFTGATE_R_SW) PID (PARAMETER IDENTIFICATION) Connect: Lead 1 Measurement / Action Lead 2 C4216 Pin 1 Ground Using a diagnostic scan tool, view the BCM LFTGATE_R_SW PID . Does the PID indicate the switch is pressed? Yes REMOVE the fused jumper wire. REPAIR the circuit. No REMOVE the fused jumper wire. GO to N7 N7 CHECK THE LIFTGATE RELEASE SWITCH INPUT CIRCUIT FOR AN OPEN Ignition OFF. Disconnect BCM C2280D. Measure: Positive Lead Measurement / Action Negative Lead C4216 Pin 1 C2280D Pin 1 Is the resistance less than 3 ohms? Yes GO to N12 No REPAIR the circuit. N8 CHECK FOR VOLTAGE TO THE LIFTGATE LATCH RELEASE MOTOR NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector. Ignition OFF. Disconnect Liftgate Latch C479. Ignition ON. Using a diagnostic scan tool, carry out the BCM self-test. Connect: Positive Lead Measurement / Action Negative Lead C479 Pin 2 Ground Unlock the doors using a door lock control switch. NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the test lamp while pressing the liftgate release switch. While pressing the liftgate release switch, monitor the test lamp. Does the test lamp momentarily illuminate? Yes GO to N9 No GO to N10 N9 CHECK THE LIFTGATE LATCH RELEASE MOTOR GROUND CIRCUIT FOR AN OPEN NOTICE: The following step uses a test lamp to simulate normal circuit loads. Use only a Rotunda Test Lamp (SGT27000) or 250-300mA incandescent bulb test lamp. To avoid connector terminal damage, use the Rotunda Flex Probe kit for the test lamp probe connection to the vehicle. Do not use the test lamp probe directly on any connector. Connect: Positive Lead Measurement / Action Negative Lead C479 Pin 2 C479 Pin 5 NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the test lamp while pressing the liftgate release switch. While pressing the liftgate release switch, monitor the test lamp. Does the test lamp momentarily illuminate? Yes INSTALL a new liftgate latch. REFER to: Liftgate Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). No REPAIR the circuit. N10 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Disconnect BCM C2280F. Measure: Positive Lead Measurement / Action Negative Lead C479 Pin 2 Ground Is the resistance greater than 10,000 ohms? Yes GO to N11 No REPAIR the circuit. N11 CHECK THE LIFTGATE LATCH RELEASE MOTOR VOLTAGE SUPPLY CIRCUIT FOR AN OPEN Measure: Positive Lead Measurement / Action Negative Lead C479 Pin 2 C2280F Pin 31 Is the resistance less than 3 ohms? Yes GO to N12 No REPAIR the circuit. N12 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION Disconnect and inspect all the BCM connectors. Repair: corrosion (install new connectors or terminals - clean module pins) damaged or bent pins - install new terminals pins pushed-out pins - install new pins as necessary Reconnect the BCM connectors and make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, VIN required to access Guided Routine (BCM) No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. Document download links> Liftgate Latch Manual Release - General Procedures - 2015 Edge Workshop Manual.pdf Liftgate Latch - Removal and Installation - 2015 Edge Workshop Manual.pdf LIFTGATE-LUGGAGE COMPARTMENT LID LATCH - Connector C479 Details - 2015 Edge.pdf LIFTGATE-LUGGAGE COMPARTMENT LID LATCH - Connector C479 Location - 2015 Edge.pdf Liftgate Release Switch - Removal and Installation - 2015 Edge Workshop Manual.pdf LIFTGATE RELEASE SWITCH - Connector C4216 Details - 2015 Edge.pdf LIFTGATE RELEASE SWITCH - Connector C4216 Location - 2015 Edge.pdf Liftgate Trim Panel - Removal and Installation - 2015 Edge Workshop Manual.pdf Body Control Module (BCM) - Connectors C2280D & C2280F Attachment Locations on BCM - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Details - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280D Location - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280F Details - 2015 Edge.pdf BODY CONTROL MODULE (BCM) - Connector C2280F Location - 2015 Edge.pdf Beyond this Pinpoint Test N diagnostic procedure, I find no Technical Service Bulletin (TSB) addressing the liftgate latching issue you describe. Good luck!

-

P1450 code Purge Valve fixed but code comes back again one month later?

Haz replied to fairlaniac's topic in 2.0L EcoBoost

From the 2017 Ford Powertrain Control/Emissions Diagnosis Manual, a multi-model/multi-engine diagnostic reference... Document download link> PINPOINT TEST HX - EVAPORATIVE EMISSION (EVAP) SYSTEM AND MONITOR.pdf If you progress toward undertaking the many circuit tests in the Pinpoint Test HX diagnostic procedure, I can provide Edge-specific connector details and location illustrations, and wiring diagrams. Good luck! -

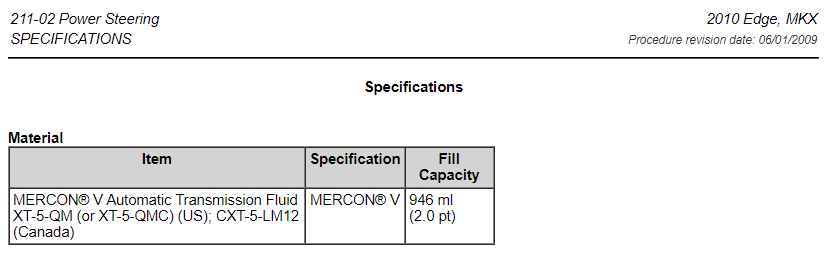

Welcome to the Forum, CEdge2010 ! From the 2010 Edge Workshop Manual... Power Steering Fluid Leak Test NOTE: This test should only be carried out if a leak in the system has not been detected during a thorough visual inspection. Refer to Inspection and Verification in this section. Remove the power steering pump reservoir cap and check the power steering fluid level. If necessary, add the specified power steering fluid. Tightly install the Power Steering Evacuation Cap onto the reservoir and connect the Vacuum Pump Kit to the Evacuation Cap. Using the Vacuum Pump Kit, apply 68-85 kPa (20-25 in-Hg) of vacuum to the power steering system. Observe the vacuum gauge for 30 seconds. If the vacuum gauge reading drops more than 3 kPa (0.88 in-Hg), a leak is present. Remove the Vacuum Pump Kit. Start the engine and insert the Dial Thermometer into the Evacuation Cap. NOTICE: Do not hold the steering wheel at the stops for an extended amount of time. Damage to the power steering pump may occur. With the engine at idle, raise the power steering fluid temperature to 74-80°C (165-176°F) by rotating the steering wheel fully to the left and right several times. Stop the engine and visually inspect the system for leaks. If a leak is evident, repair as necessary. If a leak is not evident, add the specified UV fluorescent tracer dye to the power steering fluid. Use 14.78 ml (1/2 oz) of dye solution for every 1.89L (2 qt) of power steering fluid. Start the engine. NOTICE: Do not hold the steering wheel at the stops for an extended amount of time. Damage to the power steering pump may occur. With the engine at idle, raise the power steering fluid temperature to 74-80°C (165-176°F) by rotating the steering wheel fully to the left and right several times. Stop the engine and inspect the system for traces of UV dye using the 100W/12 Volt DC UV Lamp. Repair as necessary. Document download links> Power Steering System Flushing - General Procedures - 2010 Edge Workshop Manual.pdf Power Steering System Purging - General Procedures - 2010 Edge Workshop Manual.pdf Power Steering System Filling - General Procedures - 2010 Edge Workshop Manual.pdf Good luck!

-

Blend,Mode and Recirculation

Haz replied to 2015Edge2015's topic in Interior, A.C., Heat, Interior Trim

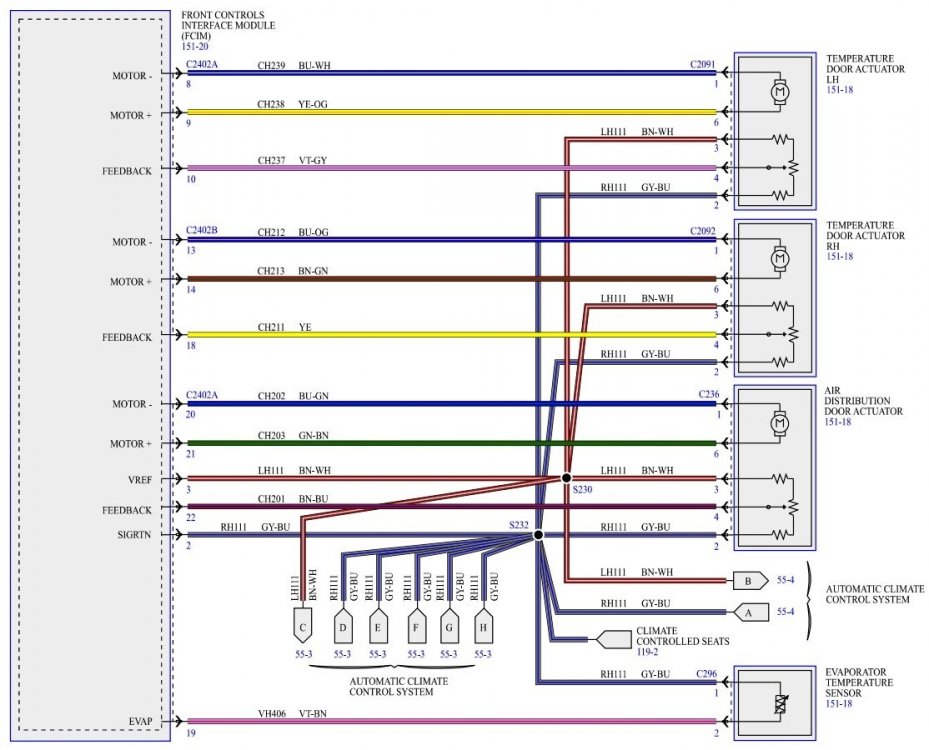

From the 2015 Edge Workshop Manual... Climate Control System - Dual Automatic Temperature Control (DATC) - Component Location Air Handling There are 4 door actuators that control the air flow into the passenger compartment: Air distribution Air inlet Driver side temperature Passenger side temperature All of the door actuators contain a reversible electric motor and a potentiometer. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the FCIM from the contact wiper indicates the position of the actuator door. The FCIM powers the actuator motors to move the doors to the desired positions. The desired door positions are calculated by the FCIM based on the set temperature, in-vehicle temperature, ambient air temperature and sunload. When an airflow mode, desired driver or passenger temperature, fresh air, or recirculation mode is selected, the FCIM moves the actuator motor in the desired direction. The FCIM sends a PWM signal to the blower motor speed control to regulate the blower speed as necessary. The blower motor speed control provides variable ground feed for the blower motor based on the input from the FCIM . A delay function provides a gradual increase or decrease in blower motor speed under all conditions. AUTO When AUTO is selected: the HVAC system operates in a manner to achieve and maintain the temperature set by the operator. the driver and passenger side temperature doors are automatically controlled by the FCIM based on the temperature setting. the A/C compressor is automatically controlled by the PCM from information sent by the FCIM , based on the temperature setting. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the blower motor speed is automatically controlled through the blower motor speed control that receives a PWM signal from the FCIM based on the temperature setting, but can be manually overridden. the FCIM controls the air inlet door to recirculate, partially recirculate or open to the fresh air position depending on the in-car temperature and humidity sensor inputs. OFF When OFF is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the blower motor is off. MAX A/C When MAX A/C is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the recirculated air indicator is illuminated (recirculated air forced on). the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. the temperature doors move to the full cool position. Air temperature can be manually overridden. the A/C button is illuminated. the A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the blower motor is commanded to the highest speed. The blower motor speed is adjustable. PANEL When PANEL mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. PANEL/FLOOR When PANEL/FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct and the instrument panel registers. A small amount of airflow from the side window demisters and defrost duct is present. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. FLOOR When FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct. A small amount of airflow from the defroster duct and side window demisters is present. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. FLOOR/DEFROST When FLOOR/DEFROST mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct, the defroster duct and the side window demisters. blended air temperature is available. Only when A/C compressor operation has been selected by pressing the A/C button (indicator on) can the airflow temperature be cooled below the outside air temperature. the blower motor is on and the speed is adjustable. MAX DEFROST When MAX DEFROST mode is selected: the recirculated air request button is disabled. The air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the defroster duct and side window demisters. A small amount of airflow from the floor duct is present. the A/C is turned on in defrost mode. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the temperature is set to the highest setting and is not adjustable. the fan is set to the highest speed and is not adjustable. MAX DEFROST can be exited by pressing the AUTO button. Climate Control System - Dual Automatic Temperature Control (DATC) - Front Controls Interface Module (FCIM) to Air Flow Door Actuators - Wiring Diagram Climate Control System - Electronic Manual Temperature Control (EMTC) - Component Location Air Handling There are 3 door actuators that control the air flow into the passenger compartment: Air distribution Air inlet Temperature All of the door actuators contain a reversible electric motor and a potentiometer. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the FCIM from the contact wiper indicates the position of the actuator door. The FCIM powers the actuator motors to move the doors to the desired positions. The desired door positions are calculated by the FCIM based on the set temperature, in-vehicle temperature, ambient air temperature and sunload. When an airflow mode, desired temperature, fresh air, or recirculation mode is selected, the FCIM moves the actuator motor in the desired direction. The FCIM sends a PWM signal to the blower motor speed control to regulate the blower speed as necessary. The blower motor speed control provides variable ground feed for the blower motor based on the input from the FCIM . A delay function provides a gradual increase or decrease in blower motor speed under all conditions. OFF When OFF is selected: the air inlet door closes, preventing outside air and allowing only recirculated air. the blower motor is off. MAX A/C When MAX A/C is selected: the air inlet door closes allowing only recirculated air. the recirculated air indicator is illuminated (recirculated air forced on). the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. the temperature door moves to the full cool position. Air temperature can be manually overridden. the A/C button is illuminated. the A/C compressor operates if the outside temperature is above approximately 0°C (32°F). the blower motor is commanded to the highest speed. The blower motor speed is adjustable. PANEL When PANEL mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the footwell vent doors and defrost vent/register doors operate in combination to direct airflow to the instrument panel registers. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. PANEL/FLOOR When PANEL/FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct and the instrument panel registers. A small amount of airflow from the side window demisters and defrost duct is present. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. FLOOR When FLOOR mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct. A small amount of airflow from the defroster duct and side window demisters is present. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. FLOOR/DEFROST When FLOOR/DEFROST mode is selected: the recirculated air request button is enabled. If the recirculated air request button is selected (indicator on), the air inlet door closes, preventing outside air from entering the passenger compartment. If the recirculated air request button is not selected (indicator off), the air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the floor duct, the defroster duct and the side window demisters. blended air temperature is available. The airflow temperature is only cooled below the outside air temperature when the A/C is commanded on. the blower motor is on and the speed is adjustable. MAX DEFROST When MAX DEFROST mode is selected: the recirculated air request button is disabled. The air inlet door opens, allowing only outside air into the passenger compartment. the air distribution doors operate in combination to direct airflow to the defroster duct and side window demisters. A small amount of airflow from the floor duct is present. the A/C is turned on in defrost mode. The A/C compressor operates as long as the outside temperature is above approximately 0°C (32°F). the temperature is set to the highest setting and is not adjustable. the fan is set to the highest speed and is not adjustable. MAX DEFROST can be exited by pressing the AUTO button. Climate Control System - Electronic Manual Temperature Control (EMTC) - Front Controls Interface Module (FCIM) to Air Flow Door Actuators - Wiring Diagram Document download links> Air Distribution Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Gateway Module A (GWM) - Removal and Installation - 2015 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Depowering - General Procedures - 2015 Edge Workshop Manual.pdf Driver Knee Airbag - Removal and Installation - 2015 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2015 Edge Workshop Manual.pdf Air Inlet Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf (Requires extensive disassembly of Instrument Panel and Floor Console not described in this document) Driver Side Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Brake Pedal and Bracket - Removal and Installation - 2015 Edge Workshop Manual.pdf Stoplamp Switch - Removal and Installation - 2015 Edge Workshop Manual.pdf Accelerator Pedal - Removal and Installation - 2015 Edge Workshop Manual.pdf Passenger Side Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf Temperature Door Actuator - Removal and Installation - 2015 Edge Workshop Manual.pdf TEMPERATURE DOOR ACTUATOR RH - Connector C2092 Details - 2015 Edge.pdf FRONT CONTROLS INTERFACE MODULE (FCIM) - Connector C2402A Details - 2015 Edge.pdf FRONT CONTROLS INTERFACE MODULE (FCIM) - Connector C2402B Details - 2015 Edge.pdf Front Controls Interface Module (FCIM) - Removal and Installation - 2015 Edge Workshop Manual.pdf From Climate Control System - Dual Automatic Temperature Control (DATC) - Diagnosis and Testing - 2015 Edge Workshop Manual... FCIM - DATC DTC CHART B1082:13 Right Temperature Damper Motor: Open Circuit This DTC sets when the module senses no voltage on the actuator motor circuit when ground is applied to drive the motor, indicating a open circuit. The motor can not move. The Temperature Control Is Inoperative Or Does Not Operate Correctly - Passenger Side Normal Operation and Fault Conditions - Temperature Door Actuator - Passenger side During an actuator calibration cycle, the module drives the temperature door until the door reaches both internal stops in the HVAC case. If the temperature door is temporarily obstructed or binding during a calibration cycle, the module may interpret this as the actual end of travel for the door. When this condition occurs and the module commands the actuator to its end of travel, the airflow may not be the expected temperature. Possible Sources Wiring, terminals or connectors Passenger side temperature door actuator FCIM PINPOINT TEST J: THE TEMPERATURE CONTROL IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY - PASSENGER SIDE NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. J1 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TO VOLTAGE Ignition OFF. Disconnect FCIM C2402A. Disconnect FCIM C2402B. Disconnect Passenger side temperature door actuator C2092. Ignition ON. Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 Ground C2092 Pin 2 Ground C2092 Pin 3 Ground C2092 Pin 4 Ground C2092 Pin 6 Ground Is any voltage present? Yes REPAIR the circuit. No GO to J2 J2 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TO GROUND Ignition OFF. Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 Ground C2092 Pin 2 Ground C2092 Pin 3 Ground C2092 Pin 4 Ground C2092 Pin 6 Ground Are the resistances greater than 10,000 ohms? Yes GO to J3 No REPAIR the circuit. J3 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR AN OPEN Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 2 C2402A Pin 2 C2092 Pin 3 C2402A Pin 3 Positive Lead Measurement / Action Negative Lead C2092 Pin 1 C2402B Pin 13 C2092 Pin 4 C2402B Pin 18 C2092 Pin 6 C2402B Pin 14 Are the resistances less than 3 ohms? Yes GO to J4 No REPAIR the circuit. J4 CHECK THE PASSENGER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TOGETHER Measure: Positive Lead Measurement / Action Negative Lead C2092 Pin 1 C2092 Pin 2 C2092 Pin 1 C2092 Pin 3 C2092 Pin 1 C2092 Pin 4 C2092 Pin 1 C2092 Pin 6 C2092 Pin 2 C2092 Pin 3 C2092 Pin 2 C2092 Pin 4 C2092 Pin 2 C2092 Pin 6 C2092 Pin 3 C2092 Pin 4 C2092 Pin 3 C2092 Pin 6 C2092 Pin 4 C2092 Pin 6 Are the resistances greater than 10,000 ohms? Yes INSTALL a new passenger side temperature door actuator. REFER to: Passenger Side Temperature Door Actuator (412-00 Climate Control System - General Information, Removal and Installation). TEST the system for normal operation. If the concern is still present, GO to J5 No REPAIR the circuit. J5 CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE) OPERATION Ignition OFF. Disconnect and inspect all FCIM connectors. Repair: corrosion (install new connector or terminals – clean module pins) damaged or bent pins – install new terminals/pins pushed-out pins – install new pins as necessary Connect all FCIM connectors. Make sure they seat and latch correctly. Operate the system and determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, VIN required to access Guided Routine (FCIM) No The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS the root cause of any connector or pin issues. Good luck!

09-20-2023.thumb.jpg.1843b76a56da3d9238e40feaa0b3cab6.jpg)

09-20-2023.thumb.jpg.1168475c48a51e517e6ee88d621c0a44.jpg)

09-20-2023.thumb.jpg.33efabd15f6d78d35312679031aaa42b.jpg)

-FordParts.thumb.jpg.ca3dff6490d4e487e562c4dbd06a216a.jpg)

-ComponentLIST-2015EdgeWorkshopManual.jpg.5cd82b4d07e932e2dd084647c83565a5.jpg)

-ComponentLocation-2015EdgeWorkshopManual.thumb.jpg.b03f6f09d5119c90db01c0f7bb649e42.jpg)

-ComponentLIST-2015EdgeWorkshopManual.jpg.0025f311e82317216513bf1ee5729809.jpg)

-ComponentLocation-2015EdgeWorkshopManual.thumb.jpg.ba46e6eb51b6145a71566f1c2cbf60a4.jpg)

toAirFlowDoorActuatorsWiringDiagram.thumb.jpg.0f96a061008a8eb2f45d5095e185220f.jpg)