Haz

Edge Member-

Posts

1,510 -

Joined

-

Last visited

-

Days Won

405

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

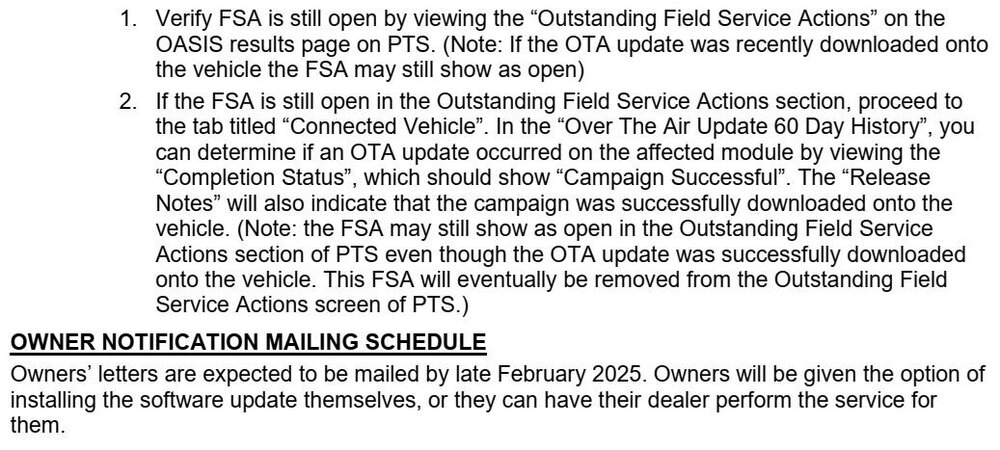

Looking at the 2021 Edge ST's history, it appears its previous DSP update did not occur through a dealership visit, so it may have been Over-The-Air (OTA), like the January 2025 SYNC4 update which is clearly identified as OTA. How long this vehicle has been waiting to receive its presently available DSP update is not clear, since I cannot view the 2021 Edge's Connected Vehicle status, which shows a 60-day history. If you are not a FordPass user, you may want to explore its capabilities. OTA software updates can sometimes become stalled as a result of unsuccessful update actions toward other prerequisite modules. The surest way to navigate multiple-module updates is to have the dealer connect the vehicle to Ford's software update server, which assesses and properly sequences the software updates. If problems arise, then the dealership can contact the Dealer Software Support Hotline (DSSH) for guidance to overcome the problem. Good luck!

-

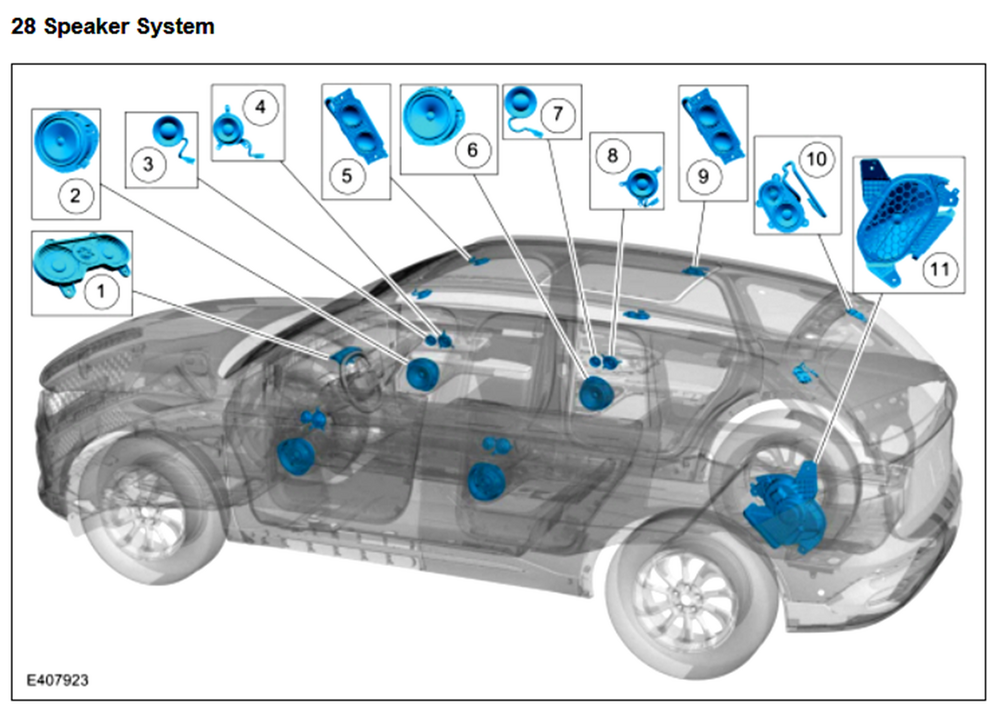

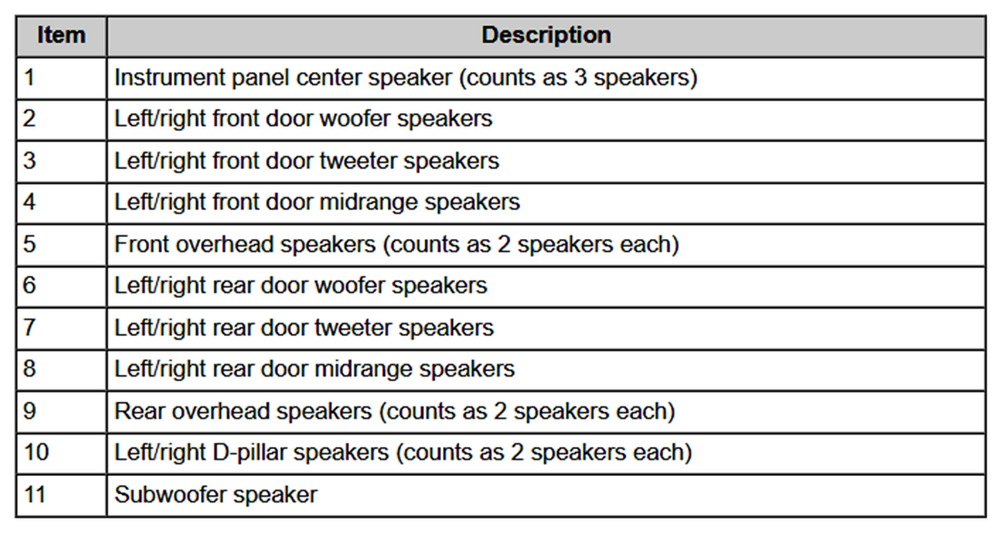

Welcome to the Forum @jonasy! It's possible that the two 2019 Edge STs do not have the same software level in their B&O 12-speaker audio system's Audio Digital Signal Processing (DSP) modules. While I'm unable to remotely view DSP software levels in 2019 model year vehicles, I checked the DSP software level in a B&O-equipped 2021 Edge ST with its last DSP update (JL3T-14C589-EA) having occurred in September 2021, and a DSP update is presently available for that specific vehicle. In the case of the 2019 Edge STs, one vehicle may have received a DSP software update that the other vehicle has not yet received. The DSP module is located behind the Driver's Side (Left Hand) Cargo Loadspace trim panel... Good luck!

-

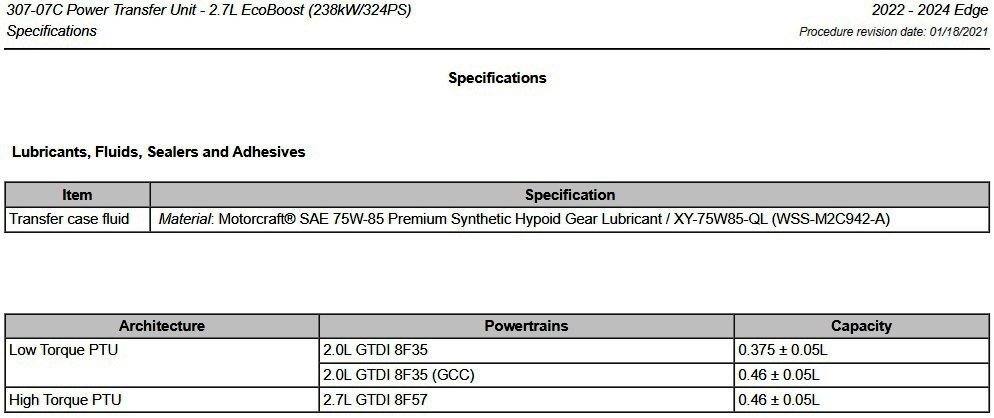

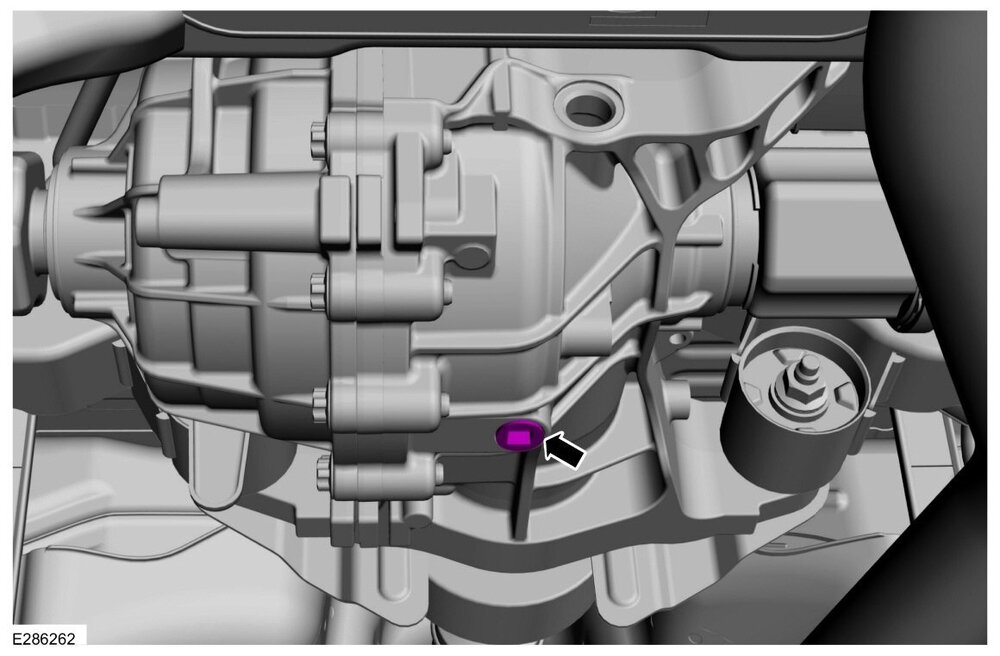

@STBEAST: From the 2022-2024 Edge Workshop Manual, including Power Transfer Unit (PTU) drain & fill procedure attached below as a PDF document... Good luck! Power Transfer Unit Draining and Filling - 2.7L EcoBoost - General Procedures - 2022-2024 Edge Workshop Manual.pdf

-

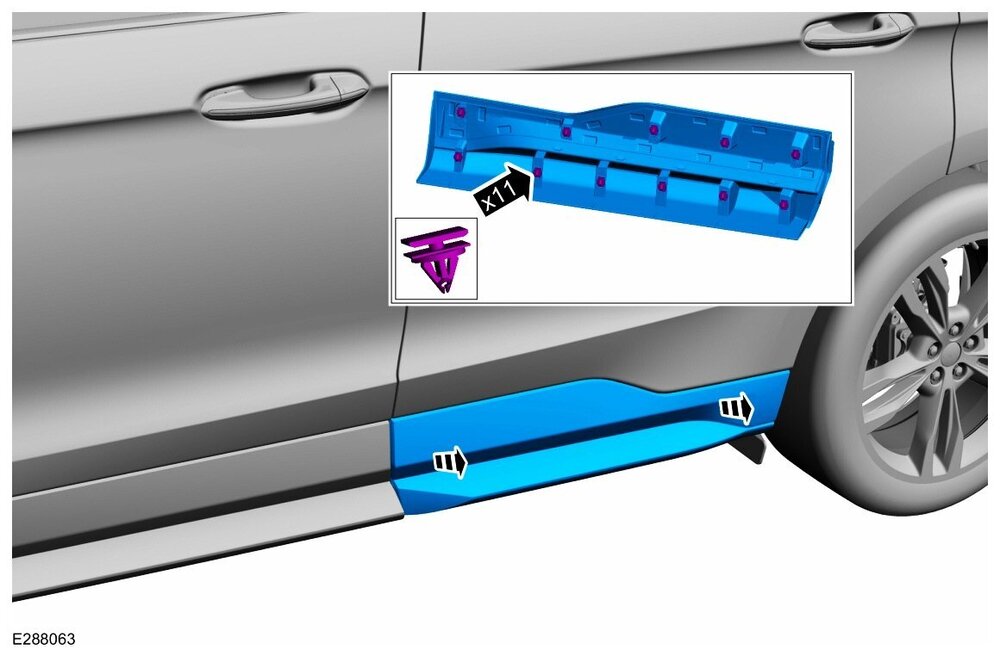

Welcome to the Forum @Kellmac! The 2020 Edge Workshop Manual indicates the Rear Door Moulding panel is retained to the body by eleven (11) clips attached to the panel's molded-in pedestals. You might try putting a square of masking tape or low-tack painter's tape on the outer face of the panel corresponding to each of the eleven pedestals, to ensure that you are directly engaging each and every retaining clip. If any of your Edge's clips appear to be damaged when compared to the below photo, replacement clips are available per Ford's online parts-selling site, and through your local dealer's Parts Department. And finally, the 2020 Edge Workshop Manual removal & installation procedure is attached below as a PDF document. Good luck! Link to this FordParts webpage Rear Door Moulding - Removal and Installation - 2020 Edge Workshop Manual.pdf

-

2015-2018 Edge Workshop Manual - Rear Differential Unit (RDU) - Filler Plug ONLY 2019-2024 Edge Workshop Manual - Rear Drive Unit (RDU) - Filler Plug 2019-2024 Edge Workshop Manual - Rear Drive Unit (RDU) - Drain Plug 2007-2014 Edge Workshop Manual - Rear Differential Unit (RDU) - Filler Plug ONLY Good luck!

-

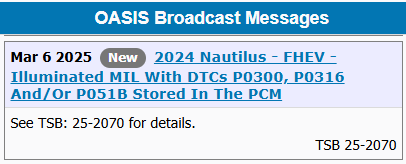

TECHNICAL SERVICE BULLETIN Illuminated MIL With DTCs P0300, P0316 And/Or P051B Stored In The PCM 25-2070 05 March 2025 This bulletin supersedes 24-2319. Reason for update: change labor operation from actual time to fixed time Model: Lincoln 2024 Nautilus FHEV Markets: North American markets only Issue: Some of the vehicles listed in the Model statement above may exhibit an illuminated MIL with DTCs P0300, P0316 and/or P051B stored in the PCM. This may be due to the software level of the PCM and the SOBDMC. Action: For vehicles that meet all of the criteria in the Issue and Model statements, follow the Service Procedure to reprogram the PCM and SOBDMC to the latest software level. Warranty Status: Eligible under provisions of New Vehicle Limited Warranty (NVLW)/Emissions Warranty/Service Part Warranty (SPW)/Service Part New Vehicle (SPNV)/Extended Service Plan (ESP) coverage. Limits/policies/prior approvals are not altered by a TSB. NVLW/Emissions Warranty/SPW/SPNV/ESP coverage limits are determined by the identified causal part and verified using the OASIS part coverage tool. Labor Times Description Operation No. Time 2024 Nautilus FHEV - Perform Software Update For PCM And SOBDMC Following TSB Procedure. (Do Not Use With Any Other Labor Operations) 252070A 0.4 Hrs. Repair/Claim Coding Causal Part: RECALEM Condition Code: 04 Service Procedure 1. Connect a battery charger such as Rotunda GRX-3590 or DCA-8000 to the 12-volt battery. NOTE: To prevent the battery saver mode from activating on the vehicle, make sure the negative cable of the charger is installed on a chassis or engine ground, and not the 12-volt battery negative terminal. Do not have the vehicle plugged into high voltage battery charger during programming. This can cause incorrect module programming. Make sure only the 12-volt battery charger is installed. 2. Reprogram the PCM and SOBDMC using the latest level software level of the FDRS scan tool. NOTE: Advise the customer this vehicle is equipped with an adaptive transmission shift strategy which allows the vehicle's computer to learn the transmission's unique parameters and improve shift quality. When the adaptive strategy is reset, the computer will begin a relearning process. This relearning process may result in firmer than normal upshifts and downshifts for several days. © 2025 Ford Motor Company All rights reserved. NOTE: The information in Technical Service Bulletins is intended for use by trained, professional technicians with the knowledge, tools, and equipment to do the job properly and safely. It informs these technicians of conditions that may occur on some vehicles, or provides information that could assist in proper vehicle service. The procedures should not be performed by "do-it-yourselfers". Do not assume that a condition described affects your car or truck. Contact a Ford or Lincoln dealership to determine whether the Bulletin applies to your vehicle. Warranty Policy and Extended Service Plan documentation determine Warranty and/or Extended Service Plan coverage unless stated otherwise in the TSB article. The information in this Technical Service Bulletin (TSB) was current at the time of printing. Ford Motor Company reserves the right to supersede this information with updates. The most recent information is available through Ford Motor Company's on-line technical resources.

- 1 reply

-

- 1

-

-

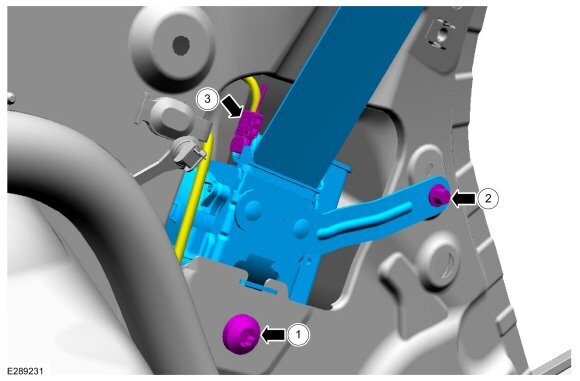

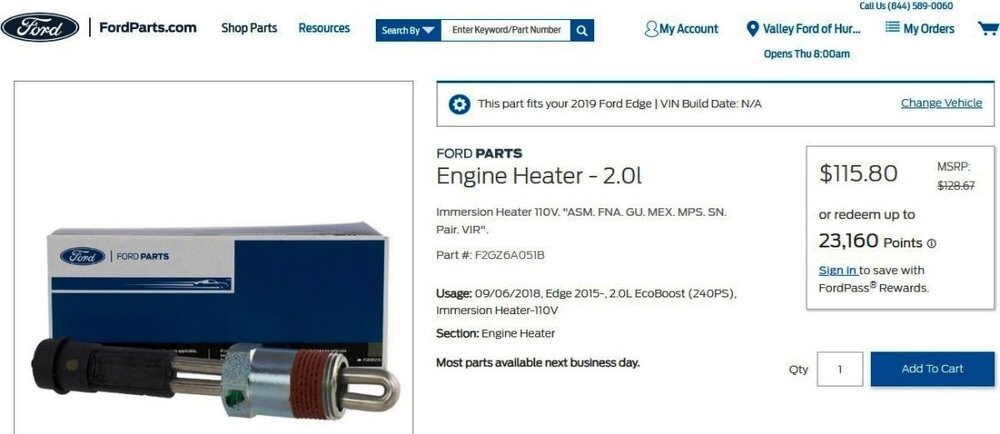

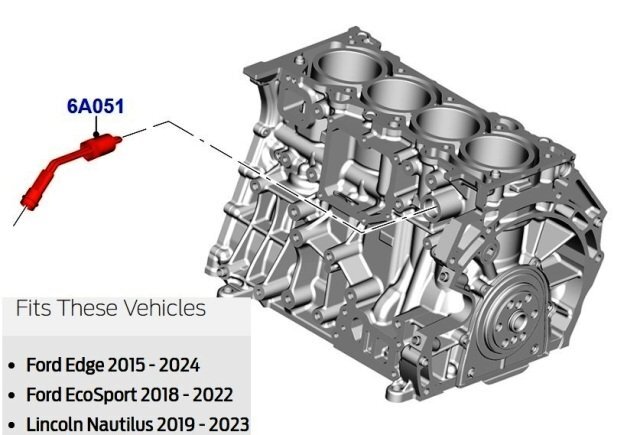

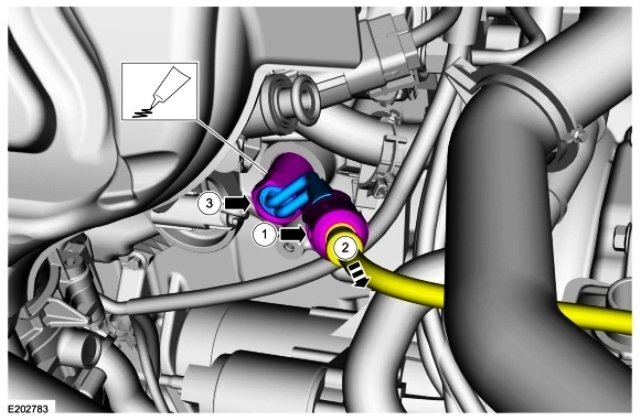

SSM 53474 2019-2024 Edge, 2019-2023 Nautilus - 2.0L - Repeat Block Heater Failure - Updated Procedure In The Workshop Manual (WSM) Some 2019-2024 Edge and 2019-2023 Nautilus vehicles equipped with a 2.0L engine may exhibit a repeat block heater failure. This may be caused by air in the engine cooling system. The WSM replacement procedure has been updated to include the Engine Cooling System Draining, Vacuum Filling and Bleeding procedure found in Section 303-03A Engine Cooling - 2.0L EcoBoost (184kW/250PS) - MI4, General Procedures as the final step. The block heater should not be tested unless all the air has been removed from the engine cooling system following this procedure. Relevant Workshop Manual sections, as PDF documents, are attached below a Workshop Manual illustration and information from Ford's online parts-selling site... Link to this FordParts webpage Block Heater - 2.0L EcoBoost - Removal and Installation - Edge-Nautilus Workshop Manual.pdf Engine Cooling System Draining, Vacuum Filling and Bleeding - 2.0L EcoBoost - General Procedures - Edge-Nautilus Workshop Manual.pdf

-

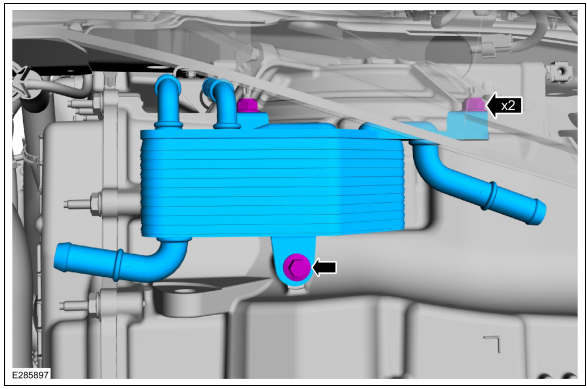

@Bunky: You are correct that the transmission cooler for the 2024 Nautilus Hybrid's HF55 Automatic Transmission is a liquid-to-air heat exchanger that presents no opportunity for engine coolant/transmission fluid cross-contamination... ...which is mounted onto the front of the (engine coolant) Radiator... The causal base part number cited in SSM 53465 -- 7869 -- resolves to the Transmission Fluid Cooler used with the 8F35 transmission... ...which is mounted beneath the 8F35 Transmission... Ford's online parts-selling site designates the 7869 Transmission Fluid Cooler as fitting the models affected by SSM 53465, though not for all listed model years... Link to this FordParts webpage Based upon its appearance and the cross-contamination failure mode it's described as producing, the 7689 Transmission Fluid Cooler is a fluid-to-fluid heat exchanger. And finally, the Transmission Fluid Cooler for the 8F57 Automatic Transmission is an integral part of the A/C Condenser, and as a fluid-to-air heat exchanger, it provides no opportunity for engine coolant/transmission fluid cross-contamination... It's fair to say, it would've been nice if the Special Service Message included the affected vehicles' engine/transmission combination(s). Good luck!

-

SSM 53465 - 2021-2024 Bronco Sport, 2020-2024 Escape/Corsair/Edge/Nautilus/Transit Connect, 2022-2024 Maverick - Erratic Shift And/Or Fluid Venting - Engine Coolant In Transmission Fluid Some 2021-2024 Bronco Sport, 2020-2024 Escape/Corsair/Edge/Nautilus/Transit Connect and 2022-2024 Maverick vehicles may exhibit erratic shifting and/or a transmission fluid venting condition. If during the preliminary inspection the transmission fluid is found to be a foamy pink color, this may indicate possible cross contamination of engine coolant and transmission fluid due to an internally leaking transmission fluid cooler assembly. When repairing or replacing the transmission assembly for an internally leaking transmission fluid cooler assembly, use causal part 7869 and applicable labor operations in Section 07 of the Service Labor Time Standards (SLTS) Manual.

-

2007 Edge Coolant reservior hose changeout

Haz replied to SD40-2's topic in Alarms, Keyless Entry, Locks & Remote Start

@SD40-2: Because the 2007 Edge Workshop Manual does not offer specific procedures for coolant hose replacement, attached below as PDF documents are Cooling System sections that may provide you insights toward your desired outcome... Good luck! Cooling System Draining, Filling and Bleeding - General Procedures - 2007 Edge Workshop Manual.pdf Radiator - Removal and Installation - 2007 Edge Workshop Manual.pdf Degas Bottle - Removal and Installation - 2007 Edge Workshop Manual.pdf Engine Cooling - Description and Operation - 2007 Edge Workshop Manual.pdf Engine Cooling - Specifications - 2007 Edge Workshop Manual.pdf Cooling Fan Motor and Shroud - Removal and Installation - 2007 Edge Workshop Manual.pdf Engine Cooling - Diagnosis and Testing - 2007 Edge Workshop Manual.pdf Thermostat - Removal and Installation - 2007 Edge Workshop Manual.pdf Intake Air System Components — Exploded View - Removal and Installation - 2007 Edge Workshop Manual.pdf Air Cleaner Outlet Pipe - Removal and Installation - 2007 Edge Workshop Manual.pdf Thermostat Housing - Removal and Installation - 2007 Edge Workshop Manual.pdf -

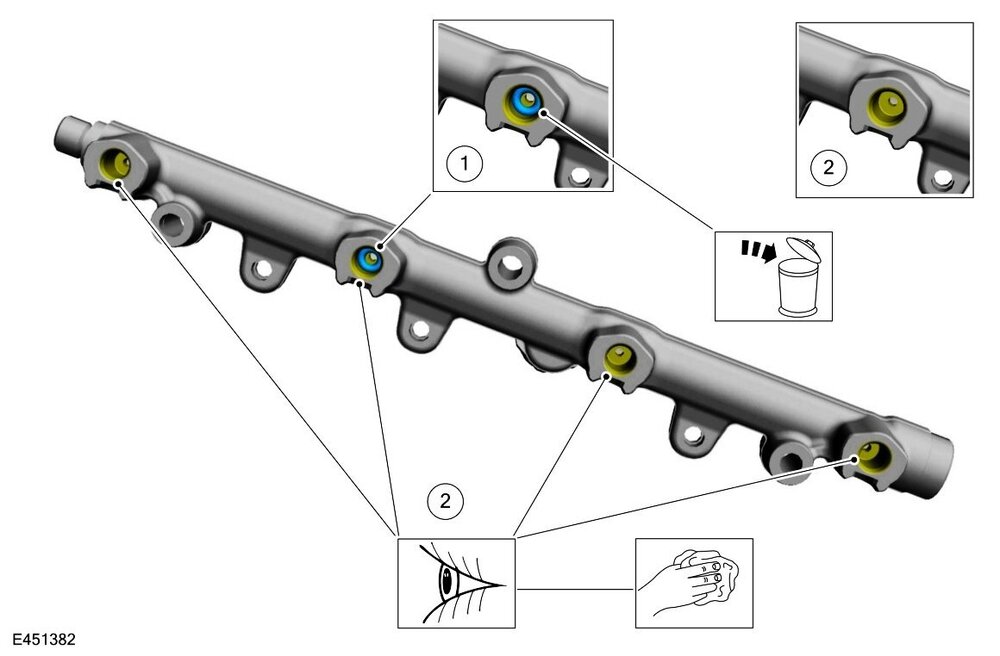

SSM 53443 2024-2025 Nautilus - Direct Injection Fuel Injector Removal Or Replacement 2024-2025 Nautilus vehicles require inspection and removal and discard of O-rings or debris that may be stuck in the direct injection fuel rail injector bores when removing or replacing the injectors for any reason. Workshop Manual (WSM), Section 303-04 Direct Fuel Injection Rail Removal and Installation has been updated to address this condition. The revised step from the referenced Workshop Manual removal and installation procedure... NOTICE: Check the fuel rail at fuel injector seating area for any sign of O-ring or its debris is present. Remove the O-ring and clean the injector bores. Inspect the fuel rail for any O-ring stuck in the injector bore. Remove O-ring. Clean the injector bores.

-

Welcome to the Forum @Shanejohn13! Attached below as PDF documents are Roof Opening Panel Front Trim removal & installation procedures for 2007-2014 Edge, 2015-2017 Edge, and 2018-2024 Edge... Good luck! Roof Opening Panel Trim — Front - Removal and Installation - 2007-2014 Edge Workshop Manual.pdf Roof Opening Panel Front Trim - Removal and Installation - 2015-2017 Edge Workshop Manual.pdf Roof Opening Panel Front Trim - Removal and Installation - 2018-2024 Edge Workshop Manual.pdf

-

Problem with camera heating

Haz replied to Iroga's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

The following information applies to 2019-2024 Edges, and most of it is different from the previously posted 2015-2018 Edge documents. @Iroga: While you have indicated no Diagnostic Trouble Codes (DTCs) are present in the Image Processing Module A (IPMA), it may be useful for you to perform diagnostic Pinpoint Test C to assess the circuits and modules involved with the Camera Windshield Defrost Heater operation, especially noting this guidance... NOTE: Before replacing the camera windshield defrost heater, windshield or IPMA for a camera windshield defrost heater concern, verify the integrity of the wiring, connectors and terminals on the camera windshield defrost heater jumper harness. Lane Keeping Symptom Chart (partial) Diagostic Trouble Codes DTC B120C:11, DTC B120C:13 Refer to Wiring Diagram for schematic and connector information. Normal Operation and Fault Conditions The IPMA supplies voltage and ground to the camera windshield defrost heater. The IPMA uses input from the front camera and the ambient air temperature data from the PCM to command the heater on and off. The heater may be commanded on if the ambient temperature is below 5°C (41°F). Possible Causes Wiring, terminals or connectors Camera windshield defrost heater IPMA DTC Fault Trigger Conditions DTC Description Fault Trigger Conditions B120C:11 Heater for Windshield Mounted Sensor: Circuit Short To Ground An on-demand and continuous memory DTC that sets in the IPMA if an excessive current draw is detected on the heater output circuit. B120C:13 Heater for Windshield Mounted Sensor: Circuit Open An on-demand and continuous memory DTC that sets in the IPMA if a lower than expected current draw is detected on the heater output circuit. Visual Inspection and Diagnostic Pre-Checks Inspect the integrity of the wiring, terminals and connectors on the jumper harness between the vehicle harness and the camera windshield defrost heater. PINPOINT TEST C DTC (DIAGNOSTIC TROUBLE CODE) B120C:11, DTC (DIAGNOSTIC TROUBLE CODE) B120C:13 NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may cause damage to the connector. Use only Rotunda Flex Probes (NUD105-R025D) NOTE: Before replacing the camera windshield defrost heater, windshield or IPMA for a camera windshield defrost heater concern, verify the integrity of the wiring, connectors and terminals on the camera windshield defrost heater jumper harness. C1 CHECK THE IPMA (IMAGE PROCESSING MODULE A) DIAGNOSTIC TROUBLE CODES (DTCS) Ignition ON. Using a diagnostic scan tool, perform the IPMA self-test. Is DTC B120C:11 or DTC B120C:13 present? Yes For DTC B120C:11, GO to C2 For DTC B120C:13, GO to C5 No The system is operating correctly at this time. INSPECT the connectors, wiring and the camera windshield defrost heater for damage or poor connections. C2 CHECK FOR SHORT TO GROUND WITH THE IPMA (IMAGE PROCESSING MODULE A) CAMERA HEATED WINDSHIELD ELEMENT DISCONNECTED Ignition OFF. Disconnect: Rain Sensor Module C914A. Ignition ON. Using a diagnostic scan tool, clear the IPMA Diagnostic Trouble Codes (DTCs). Perform the IPMA self-test. Is DTC B120C:11 present? Yes GO to C3 No INSTALL a new windshield. REFER to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures). C3 CHECK THE IPMA (IMAGE PROCESSING MODULE A) CAMERA HEATED WINDSHIELD ELEMENT OUTPUT CIRCUIT FOR A SHORT TO GROUND Ignition OFF. Disconnect: IPMA C9224. Measure: Positive Lead Measurement / Action Negative Lead C9224 Pin 8 Ground Is the resistance greater than 10,000 ohms? Yes GO to C4 No REPAIR the circuit. After the repair, CLEAR the DTC , CYCLE the ignition, and RUN the IPMA on-demand self-test to re-enable the circuit. C4 CHECK IPMA (IMAGE PROCESSING MODULE A) CAMERA HEATED ELEMENT CIRCUITS FOR A SHORT TOGETHER Measure: Positive Lead Measurement / Action Negative Lead C9224 Pin 8 C9224 Pin 1 Is the resistance greater than 10,000 ohms? Yes GO to C5 No REPAIR the circuits. After the repair, CLEAR the DTC , CYCLE the ignition, and RUN the IPMA on demand self-test to re-enable the circuit. C5 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) B120C:13 WITH THE IPMA (IMAGE PROCESSING MODULE A) CAMERA HEATED ELEMENT CIRCUITS JUMPERED TOGETHER Ignition OFF. Disconnect: Rain Sensor Module C914A. Connect: Lead 1 Measurement / Action Lead 2 C914A Pin 1 C914A Pin 3 Ignition ON. Using a diagnostic scan tool, clear the IPMA Diagnostic Trouble Codes (DTCs). Perform the IPMA self-test. Is DTC B120C:11 present? Yes REMOVE the fused jumper wire. INSTALL a new windshield. REFER to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures). No REMOVE the fused jumper wire. GO to C6 C6 CHECK THE IPMA (IMAGE PROCESSING MODULE A) CAMERA HEATED WINDSHIELD ELEMENT CIRCUITS FOR AN OPEN Ignition OFF. Disconnect: IPMA C9224. Measure: Positive Lead Measurement / Action Negative Lead C9224 Pin 8 C914A Pin 3 C9224 Pin 1 C914A Pin 1 Are the resistances less than 3 ohms? Yes GO to C7 No REPAIR the affected circuit. C7 CHECK FOR CORRECT IPMA (IMAGE PROCESSING MODULE A) OPERATION Disconnect and inspect all IPMA connectors and related in-line connectors. Repair: corrosion (install new connector or terminals - clean module pins) damaged or bent pins - install new terminals/pins pushed-out pins - install new pins as necessary Reconnect the IPMA connectors and related in-line connectors. Make sure they seat and latch correctly. Operate the system to determine if the concern is still present. Is the concern still present? Yes CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a TSB exists for this concern, DISCONTINUE this test and FOLLOW the TSB instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new IPMA REFER to: Image Processing Module A (IPMA) (419-07 Lane Keeping System, Removal and Installation). No The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause of any connector or pin issues. Related information is attached below as PDF documents... Good luck! IMAGE PROCESSING MODULE A (IPMA) - Removal and Installation - 2019 Edge Workshop Manual.pdf Interior Rear View Mirror - Removal and Installation - 2019 Edge Workshop Manual.pdf Rain Sensor - Removal and Installation - 2019 Edge Workshop Manual.pdf Body Control Module (BCM) - Fuse F36 (15 amp) Location Red-Box Highlighted - 2019 Edge.pdf RAIN SENSOR - Heater Pwr-Gnd Circuits Depicted In This Wiring Diagram - 2019 Edge.pdf RAIN SENSOR - Connector C914A Location - 2019 Edge.pdf RAIN SENSOR - Connector C914A Pinout - 2019 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Heater Pwr-Gnd Supplied Via Rain Sensor Conector C914 Pins 1 & 3 - Wiring Diagram - 2019 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Power Distribution Wiring Diagram - 2019 Edge.pdf Rain Sensor, IPMA, Heater - Ground Termination G304 Location - 2019 Edge.pdf Rain Sensor, IPMA, Heater - Ground Splices S912 & S913 Location - 2019 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Ground Wiring Diagram - 2019 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Connector C9224 Pinout - 2019 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Connector C9224 Location - 2019 Edge.pdf -

Problem with camera heating

Haz replied to Iroga's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

Welcome to the Forum @Iroga! Absent you mentioning your Edge's model year, I pulled the following 2015-2018 Edge documents to supplement @Wubster100's research... Good luck! Body Control Module (BCM) - Fuse F36 (15 amp) Location Red-Box Highlighted - 2015 Edge.pdf Lane Keeping System - Component Location - Description and Operation - 2015 Edge Workshop Manual.pdf Body Control Module (BCM) - Fuse F36 (15 amp) Power Distribution Wiring Diagram - 2015 Edge.pdf Interior Rear View Mirror - Removal and Installation - 2015 Edge Workshop Manual.pdf Image Processing Module A (IPMA) Camera Heated Windshield Element - Removal and Installation - 2015 Edge Workshop Manual.pdf Body Control Module (BCM) - Conector-Fuse-Relay Locations Illustration - 2015 Edge.pdf AUTO-DIMMING INTERIOR MIRROR - Connector C9012 Loction- 2015 Edge.pdf AUTO-DIMMING INTERIOR MIRROR - Connector C9012 - 2015 Edge.pdf CAMERA WINDSHIELD DEFROST HEATER - Connectors C9048A & C9048B Loction - 2015 Edge.pdf CAMERA WINDSHIELD DEFROST HEATER - Connector C9048A - 2015 Edge.pdf CAMERA WINDSHIELD DEFROST HEATER - Connector C9048B - 2015 Edge.pdf IPMA-Camera Windshield Defrost Heater - Wiring Diagram - 2015 Edge.pdf -

Windshield Replacement

Haz replied to 1004ron's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

@Wubster100: Requested information is attached below as PDF documents... Good luck! Rain Sensor Module - Connector C914 Pinout - 2021 Edge.pdf Rain Sensor Module - Connector C914 Location - 2021 Edge.pdf Rain Sensor Module - Power Distribution Wiring Diagram - 2021 Edge.pdf Rain Sensor Module - Grounds Wiring Diagram - 2021 Edge.pdf Rain Sensor Module with Adaptive Cruise - Wiring Diagram - 2021 Edge.pdf IMAGE PROCESSING MODULE A (IPMA) - Connector C9224 Pinout - 2021 Edge.pdf Rain Sensor Module - Wiring Diagram - 2021 Edge.pdf Wipers and Washers - Rain Sensor Wiring Diagram 81-2 Extension - 2021 Edge.pdf Wipers and Washers - Rain Sensor Wiring Diagram 81-1 Extension - 2021 Edge.pdf -

Good luck! 360 Camera - Wiring Diagram 2 - 2024 Edge - China.pdf 360 Camera - Wiring Diagram 1 - 2024 Edge - China.pdf Parking Aid - Component Location - Description and Operation - 2024 Edge Workshop Manual - China.pdf Side Parking Aid Camera - Removal and Installation - 2024 Edge Workshop Manual - China.pdf

-

Welcome to the Forum @RedMtDave! While their inventory status could be faulty, these online OEM Ford Parts sellers show a Right Hand and a Left Hand as being in stock and available to ship. Good luck!

-

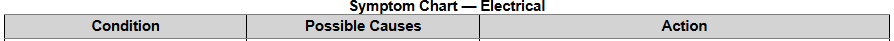

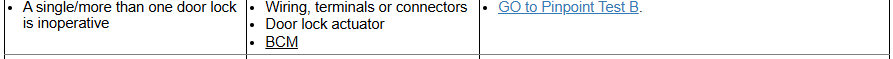

Welcome to the Forum @Strange locks! Since you are seeing lock plunger movement while the door remains locked, it's possible the door lock rod is binding or bent, or the door latch's power lock actuator has weakened. From the 2013 Edge Workshop Manual... Pinpoint Test B: A Single/More Than One Door Lock Is Inoperative Refer to Wiring Diagrams Cell 110 , Power Door Locks for schematic and connector information. Normal Operation The Body Control Module (BCM) supplies voltage to the lock all relay, the unlock driver door relay or unlock all relay based upon input from the door lock control switches, the Remote Keyless Entry (RKE) transmitter, or the keyless entry keypad. Upon a lock request, the BCM supplies voltage on the all door lock circuit and ground on the driver and passenger door unlock circuits. Upon an unlock request, the voltage and ground are reversed on the previously listed circuits. When the door lock and unlock relays are not energized they are connected to ground. A dedicated BCM ground circuit is provided only for the lock and unlock relays. This pinpoint test is intended to diagnose the following: Wiring, terminals or connectors Door lock actuator BCM PINPOINT TEST B : A SINGLE/MORE THAN ONE DOOR LOCK IS INOPERATIVE NOTICE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector. B1 CHECK THE DOOR LATCH FOR BINDING Lock and unlock the inoperative door lock using the door lock rod. Does the door lock and unlock? Yes GO to B3. No GO to B2. B2 CHECK THE LOCK ROD FOR BINDING Operate the door lock rod manually while observing the door lock rod for any binding or if the rod is bent. Is the door lock rod bent or binding? Yes REPAIR as necessary. TEST the system for normal operation. No INSTALL a new door latch. REFER to Front Door Latch or Rear Door Latch in this section. TEST the system for normal operation. B3 CHECK THE ALL LOCK OUTPUT CIRCUIT FOR VOLTAGE Ignition OFF. Disconnect: Inoperative Door Lock Actuator . NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the meter while pressing the door lock control switch. While pressing the door lock control switch in the LOCK position, measure the voltage between the inoperative door lock actuator, harness side and ground as follows: Inoperative Door Lock Actuator Connector-Pin Circuit LH front C525 Pin 4 CPL11 (GY/BN) RH front C603 Pin 4 CPL11 (GY/BN) LH rear C704 Pin 4 CPL11 (GY/BN) RH rear C804 Pin 4 CPL11 (GY/BN) Is the voltage momentarily greater than 10 volts? Yes GO to B4. No REPAIR circuit CPL11 (GY/BN) for an open. TEST the system for normal operation. B4 CHECK THE UNLOCK OUTPUT CIRCUIT FOR VOLTAGE NOTE: The BCM only supplies voltage to the actuator momentarily. It is important to monitor the meter while pressing the door lock control switch. While pressing the door lock control switch in the UNLOCK position, measure the voltage between the inoperative door lock actuator, harness side and ground as follows: Inoperative Door Lock Actuator Connector-Pin Circuit LH front C525 Pin 3 CPL51 (BU/GN) RH front C603 Pin 3 CPL52 (VT/GY) LH rear C704 Pin 3 CPL52 (VT/GY) RH rear C804 Pin 3 CPL52 (VT/GY) Is the voltage momentarily greater than 10 volts? Yes INSTALL a new door latch. REFER to Front Door Latch or Rear Door Latch in this section. No GO to B5. B5 CHECK THE UNLOCK OUTPUT CIRCUIT FOR AN OPEN Disconnect: BCM C2280D . Measure the resistance between the BCM , harness side and the inoperative door lock actuator, harness side as follows: BCM Connector-Pin Inoperative Door Lock Actuator Connector-Pin Circuit C2280D Pin 21 LH front C525 Pin 3 CPL51 (BU/GN) C2280D Pin 31 RH front C603 Pin 3 CPL52 (VT/GY) C2280D Pin 31 LH rear C704 Pin 3 CPL52 (VT/GY) C2280D Pin 31 RH rear C804 Pin 3 CPL52 (VT/GY) Is the resistance less than 5 ohms? Yes GO to B6. No REPAIR the circuit for an open. TEST the system for normal operation. B6 CHECK FOR CORRECT BCM OPERATION Disconnect all the BCM connectors. Check for: corrosion damaged pins pushed-out pins Connect all the BCM connectors and make sure they seat correctly. Operate the system and verify the concern is still present. Is the concern still present? Yes INSTALL a new BCM . REFER to Section 419-10. TEST the system for normal operation. No The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. Additional Workshop Manual procedures are attached below as PDF documents... Good luck! Front Door Latch - Removal and Installation - 2013 Edge Workshop Manual.pdf Door Trim Panel — Front - Removal and Installation - 2013 Edge Workshop Manual.pdf

-

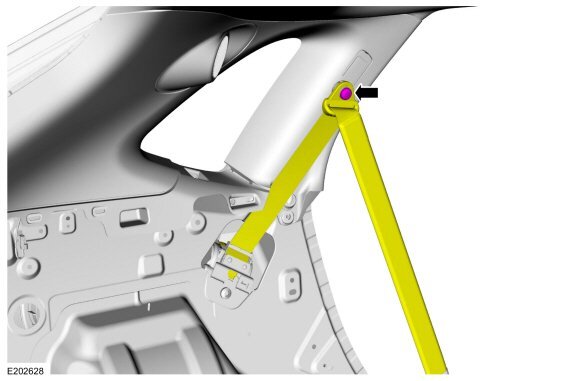

2024 Edge rattle noise from rear cargo trim panel

Haz replied to lasseventies's topic in 2.0L EcoBoost

Welcome to the Forum @lasseventies! As your highlighted illustration and your comment indicates, the rear seatbelt retractor lies beneath the trim panel, and it contains a pyrotechnic (mildly explosive) device to pretension the belt in event of a crash. Because your Edge is under warranty and within its Low Time In Service (LTIS) period, during which repairs are extensively documented and reported back to Ford, you really should contact your dealer to have a professional technician diagnose and correct the noise's root cause, which may be directly related to the seatbelt retractor assembly. Good luck!- 21 replies

-

- 2

-

-

Welcome to the Forum @kelster! Related procedures from the 2022-2024 Edge Workshop Manual are attached below as PDF documents... Good luck! High Mounted Stoplamp - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf Liftgate Trim Panel - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf Rear Spoiler - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf

-

SSM 53377 2024 Nautilus, 2025 Aviator - No Audio/Sound - 24 Channel Audio Digital Signal Processing Module (DSP) (Minor Feature Code IDBBN) No Communication Some 2024 Nautilus and 2025 Aviator vehicles equipped with a 24 channel audio digital signal processing module (DSP) (minor feature code IDBBN) may exhibit a no audio/sound condition with no communication with DSP. To confirm a vehicle is built with a certain minor feature code, review the build information by double-clicking the vehicle identification number (VIN) in the upper left corner in the Professional Technician System (PTS). This concern may be due to software in the DSP. To determine if it is a software concern, remove the DSP fuse, F40 for Aviator or F138 for Nautilus, and inspect the fuse for an open and make sure the fuse has proper blade contact. After one minute, reinstall the good fuse. If the concern is still present or a fuse concern is found, continue with normal Workshop Manual diagnostics, Section 415-00 Information and Entertainment System > General Information > Diagnosis and Testing. If communication has been re-established with the DSP, reprogram the DSP using the latest software level of the Ford Diagnosis and Repair System (FDRS) scan tool. For claiming, use causal part 18B849 and applicable labor operations in Section 10 of the Service Labor Time Standards (SLTS) Manual. The involved audio system is the Revel Ultima 3D with 28-speakers, installed on 2024 Nautilus Reserve III 203A and 2024 Nautilus Black Label editions... Information and Entertainment System - Component Location Gratitude to @Bunky for the heads-up!

- 1 reply

-

- 3

-

-

GENERAL SERVICE BULLETIN Tire Pressure Monitoring Systems (TPMS) Identification 25-7012 10 February 2025 This bulletin supersedes 23-7172. Reason for update: revised Table 1 (Figure 40) Summary This article supersedes GSB 23-7172 to update the vehicle model years affected and Service Information. This bulletin contains information on TPMS identification of Ford versus non-Ford sensors along with warrantable versus non-warrantable concerns and examples. Service Information Tires Overview Tires are designed to operate within a specific range of air pressures. The recommended inflation pressure is printed on the decal on the driver's door jamb (B-Pillar). The decal specifies the proper tire inflation. Tire pressure should be checked monthly as recommended in the Owner's Manual because all tires lose pressure over time. A tire's inflation pressure cannot be judged by appearance alone. By the time a low profile radial tire looks low, it may already be 10 to 15 PSI underinflated. The accuracy of some new inexpensive tire pressure gauges can be off by several PSI. Checking tire inflation pressure requires an accurate tire pressure gauge. TPMS Technology When the vehicle begins to move, a switch inside the sensor activates the pressure measurement and signal sending function. At about 20 mph (32 km/h), the sensor begins measuring the pressure every 30 seconds and transmits the results once each minute to the control module. The sensors transmit tire pressure data to the control module at 315 MHz or 433 MHz depending on the vehicle model year. Trailer TPMS and most export vehicles use 433 MHz. After inflating the tires to the recommended inflation pressure, the vehicle must be driven at 20 mph (32 km/h) or more for a few minutes for the light to turn off. Ford Original Equipment (OE) Sensor (Edison Housing) Markings And Part Details (Figures 1-2) Figure 1 Item Description 1 Sensor ID 2 Ford Part Number 3 Sensor Build Date (Year/Month/Day) Figure 2 Item Description 1 FoMoCo Label 2 Pressure Port 3 Do Not Discard Warning 4 FCC Identification and Frequency Ford OE Sensor (Potted Faraday) Markings And Part Details (Figures 3-4) Figure 3 Item Description 1 Sensor ID 2 Ford Part Number 3 Sensor Build Date (Year/Month/Day) Figure 4 Item Description 1 FoMoCo Label 2 Pressure Port 3 Do Not Discard Warning 4 FCC Identification and Frequency Ford OE Sensor (Faraday) Markings And Part Details (Figures 5-6) Figure 5 Item Description 1 FoMoCO Label 2 Sensor Frequency 3 Sensor Build Date (Year/Month/Day) 4 Pressure Port 5 Sensor ID 6 FCC Identification 7 Ford Part Number Figure 6 Item Description 1 Do Not Discard Warning 2 Visual Identifier (Part Specific) Ford OE Sensor (MHSSI) Markings And Part Details (Figures 7-8) Figure 7 Item Description 1 Sensor ID 2 Ford Part Number 3 Sensor Build Date (Year/Month/Day) 4 Visual Identifier (Part Specific) 5 Sensor Frequency 6 FCC Identification 7 FoMoCo Label 8 Pressure Port Figure 8 Item Description 1 Do Not Discard Warning Ford OE Sensor (Burnell) Markings And Part Details (Figure 9) Figure 9 Item Description 1 Sensor ID 2 Ford Part Number 3 Sensor Build Date (Year/Month/Day) 4 Visual Identifier (Part Specific) 5 Sensor Frequency 6 FCC Identification 7 FoMoCo Label 8 Pressure Port 9 Do Not Discard Warning Ford OE Sensor (Steel Carcass) Markings And Part Details (Figures 10-11) Figure 10 Item Description 1 Sensor ID 2 FoMoCo Label 3 Pressure Port 4 Visual Identifier (Part Specific) 5 FCC Identification 6 Sensor Frequency Figure 11 Item Description 1 Ford Part Number 2 Sensor Build Date (Year/Month/Day) 3 Do Not Discard Warning Ford OE Sensor (Trailer) Markings And Part Details (Figures 12-13) Figure 12 Item Description 1 Ford Part Number 2 Sensor Build Date (Year/Month/Day) 3 Sensor ID 4 Sensor Frequency 5 FoMoCo Label 6 FCC Identification Figure 13 Item Description 1 Pressure Port 2 Do Not Discard Warning Ford OE Sensor (Trailer Steel Carcass) Markings And Part Details (Figures 14-15) Figure 14 Item Description 1 Sensor ID 2 FoMoCo Label 3 Sensor Frequency 4 FCC Identification 5 Pressure Port Figure 15 Item Description 1 Ford Part Number 2 Sensor Build Date (Year/Month/Day) 3 Do Not Discard Warning Ford OE Sensor (Edison/Faraday) Components (Figures 16-17) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 16 Item Description 1 Cap 2 Valve Stem 3 Valve Air Port 4 Bolt Figure 17 Item Description 1 Cap 2 Valve Stem 3 Valve Air Port 4 Bolt Ford OE Sensor (Bolt-On Faraday) Components (Figure 18) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 18 Item Description 1 Cap 2 Hex Nut 3 Bolt 4 Washer 5 Valve Air Port 6 Valve Stem Ford OE Sensor (MHSSI) Components (Figure 19) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 19 Item Description 1 Cap 2 Valve Stem 3 Valve Air Port 4 Bolt Ford OE Sensor (Burnell) Components (Figure 20) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 20 Item Description 1 Cap 2 Valve Stem 3 Valve Air Port 4 Bolt Ford OE Sensor (Steel Carcass - Straight) Components (Figure 21) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 21 Item Description 1 Washer 2 Hex Nut 3 Cap 4 Valve Stem 5 Bolt 6 Valve Air Port (flows through bolt) Ford OE Sensor (Steel Carcass - Bent) Components (Figure 22) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 22 Item Description 1 Cap 2 Washer 3 Hex Nut 4 Valve Stem 5 Bolt 6 Valve Air Port (flows through bolt) Ford OE Sensor (Trailer) Components (Figure 23) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 23 Item Description 1 Cap 2 Valve Stem 3 Valve Air Port 4 Hex Nut 5 Washer Ford OE Sensor (Trailer Steel Carcass) Components (Figure 24) NOTE: When replacing the valve, make sure to replace the valve only, not the entire sensor kit. Otherwise, this is an over-repair and not warrantable. Figure 24 Item Description 1 Cap 2 Valve Stem 3 Washer 4 Hex Nut 5 Bolt 6 Valve Air Port (flows through bolt) Identifying Correct Ford OE Sensor (DE8T / Edison) For A Particular Vehicle (Figure 25) Figure 25 1 - DE8T-1A180-** Engineering Part Number Description DE8T-1A180-** 315 MHz Edison Identifying Correct Ford OE Sensor (GL3T / Faraday) For A Particular Vehicle (Figure 26) Figure 26 2 - GL3T-1A180-** Engineering Part Number Description GL3T-1A180-AA 315 MHz Faraday GL3T-1A180-CA 433 MHz Faraday Identifying Correct Ford OE Sensor (GL3T / Potted Faraday) For A Particular Vehicle (Figure 27) Figure 27 2 - GL3T-1A180-** Engineering Part Number Description GL3T-1A180-GA 315 MHz Faraday - High Speed Valve GL3T-1A180-GB 315 MHz Faraday - High Speed Valve GL3T-1A180-HA 433 MHz Faraday GL3T-1A180-HB 433 MHz Faraday Identifying Correct Ford OE Sensor (ML3T / Potted Faraday) For A Particular Vehicle (Figures 28-29) Figure 28 Figure 29 3 - ML3T-1A180-** Engineering Part Number Description ML3T-1A180-AA 315 MHz Potted Faraday ML3T-1A180-CA 433 MHz Potted Faraday (Grey Enclosure) Identifying Correct Ford OE Sensor (F2GT / Faraday) For A Particular Vehicle (Figure 30) Figure 30 4 - F2GT-1A180-** Engineering Part Number Description F2GT-1A180-AA 315 MHz Faraday - Low Speed Valve F2GT-1A180-AB 315 MHz Faraday - Low Speed Valve F2GT-1A180-AC 315 MHz Faraday - Low Speed Valve F2GT-1A180-AD 315 MHz Faraday - Low Speed Valve F2GT-1A180-AE 315 MHz Faraday - Low Speed Valve F2GT-1A180-EA 433 MHz Faraday - Low Speed Valve F2GT-1A180-EB 433 MHz Faraday - Low Speed Valve Identifying Correct Ford OE Sensor (HC3T / Faraday) For A Particular Vehicle (Figure 31) Figure 31 5 - HC3T-1A180-** Engineering Part Number Description HC3T-1A180-AA 315 MHz Faraday - High Speed Valve HC3T-1A180-AB 315 MHz Faraday - High Speed Valve HC3T-1A180-AC 315 MHz Faraday - High Speed Valve HC3T-1A180-AD 315 MHz Faraday - High Speed Valve HC3T-1A180-AE 315 MHz Faraday - High Speed Valve HC3T-1A180-GA 315 MHz Faraday - High Speed Valve HC3T-1A180-GB 315 MHz Faraday - High Speed Valve Identifying Correct Ford OE Sensor (FR3V / Bolt-On Faraday) For A Particular Vehicle (Figure 32) Figure 32 6 - FR3V-1A180-** Engineering Part Number Description FR3V-1A180-AA 315 MHz Faraday - Bolt-On Valve FR3V-1A180-AB 315 MHz Faraday - Bolt-On Valve FR3V-1A180-AC 315 MHz Faraday - Bolt-On Valve FR3V-1A180-CC 433 MHz Faraday - Bolt-On Valve FR3V-1A180-GB 315 MHz Faraday - Bolt-On Valve E-Coated Washer FR3V-1A180-HB 433 MHz Faraday - Bolt-On Valve E-Coated Washer Identifying Correct Ford OE Sensor (JX7T / MHSSI) For A Particular Vehicle (Figure 33) Figure 33 7 - JX7T-1A180-** Engineering Part Number Description JX7T-1A180-AA 315 MHz MHSSI - High Speed Valve JX7T-1A180-EA 315 MHz MHSSI - Low Speed Valve Identifying Correct Ford OE Sensor (PR3T / Burnell) For A Particular Vehicle (Figure 34) Figure 34 8 - PR3T-1A180-** Engineering Part Number Description PR3T-1A180-AB 315 MHz Burnell - Low Speed Valve PR3T-1A180-CB 433 MHz Burnell - High Speed Valve PR3T-1A180-EB 315 MHz Burnell - Bolt-On Valve PR3T-1A180-GB 433 MHz Burnell - Bolt-On Valve PR3T-1A180-KB 433 MHz Burnell - Low Speed Valve #2 PR3T-1A180-MB 433 MHz Burnell - Low Speed Valve Identifying Correct Ford OE Sensor (PC3T / Steel Carcass) For A Particular Vehicle (Figures 35-36) Figure 35 Figure 36 9 - PC3T-1A180-** Engineering Part Number Description PC3T-1A180-CA 433 MHz Steel Carcass Production Steel Wheel Valve (Bent Brass) PC3T-1A180-GB 433 MHz Steel Carcass Production Alloy Wheel Valve Identifying Correct Ford OE Sensor For Trailer TPMS (Figure 37) Figure 37 10 - HC3T-1A180-** Engineering Part Number Description HC3T-1A180-CA 433 MHz Trailer Sensor HC3T-1A180-CB 433 MHz Trailer Sensor HC3T-1A180-CC 433 MHz Trailer Sensor Identifying Correct Ford OE Sensor For Steel Carcass Trailer TPMS (Figures 38-39) Figure 38 Figure 39 11 - PC3T-1A180-** Engineering Part Number Description PC3T-1A180-JB 433 MHz Trailer Steel Carcass Sensor TPMS Identification Chart (Figure 40) The numbers in this chart identify the type of sensors for each vehicle program. The numbers are in the upper left corner of the tables in Figures 25-39. Figure 40 - TPMS Identification Chart Model 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 Aviator 7 7 7 8 8 Bronco 3 3 3 3 8 Bronco Sport 4 4 4 4 8 Continental 4 4 4 4 4 C-Max 1 1 Corsair 7 7 7 7 7 7 EcoSport 4 4 4 4 Edge 4 4 5 5 2, 5 2, 4 3, 4 3, 4 3, 4 3, 4 Escape 1 1 1 1 1 7 7 7 7 7 7 E-Series 1 1 1 1 1 2, 6 2, 6 2, 3 2, 3 2, 3 8 Expedition 1 1 1 2, 5 2, 5 2 2 2, 3 3 3 8 Explorer / Police Interceptor Utility 1 4 4 4 4 7 7 7 7 8 8 F-150 4 2 2 2 2 2 3 3 3 3 3 F-150 Lightning 3 3 3 3 3 F-150 Raptor 2 2 2 2 2 3 3 3 3 3 F-Super Duty 1 1 5, 6 2, 5, 6 2, 5, 6 2, 5, 6 2, 6 2, 3, 6 3, 6 3, 6 6, 8 Fiesta 1 1 1 4 4 4 Flex 1 1 1 1 1 Focus 1 1 1 1 Ford GT * * * * * * Fusion 1 1 5 5 5 5 Maverick 4 4 4 4 8 MKC 1 1 1 5 5 MKS 1 1 MKT 1 1 1 1 1 MKX 4 4 2, 4 2, 4 MKZ 1 1 5 5 5 5 Mustang 4 4 4 4 4 4 4 4 4 4 8 Mustang Mach-E 4 4 4 8 Mustang SVT ** 6 6 6 6 6 6 6 6 6 6 Nautilus 2, 5 2, 4 3, 4 3, 4 3, 4 3, 4 3, 4 Navigator 1 1 1 2, 5 2, 5 2 2 2, 3 3 3 8 Ranger 5 5 3 3 3 3 8 Taurus / Police Interceptor Sedan 1 1 1 1 1 Transit 1 1 1 1 1 6, 7 6, 7 6, 7 6, 7 6, 7 6, 8 Transit Connect 1 1 1 4 4 4 4 4 4 8 Trailer TPMS Kit 10 10 10 10 10 10 10, 11 11 11 Figure 40 legend * Ford GT uses a specialized black anodized bolt-on valve. The part number prefix for this is HG7Z. ** Mustang SVT uses a bolt-on valve. The part number prefix for this is DR3V. TPMS Sensor Non-Warrantable Issues With the variety of sensors that come equipped on Ford/Lincoln vehicles, make sure the sensor type is carefully identified and the correct mount and dismount procedure is used for each type of TPMS sensor. Damage to the TPMS sensor is identifiable with each part being reviewed prior to warranty approval. The sensor may not respond for a number of non-warrantable reasons that require the replacement of the sensor. They are: • Damage due to improper tire mount and/or dismount procedure • Damage due to being run on a flat or severely under-inflated tire • Damage due to impact • Damage due to improper removal of the valve stem • Sensor replaced due to the use of a tire sealant • Pressure port clogged due to the use of sealants or other materials (rubber, grease, balancing materials, etc.) • Damage due to mounting on wheels not designed to accommodate TPMS sensors properly Other Non-Warrantable Conditions: • Wrong frequency parts • Wrong sensor type (both Ford and non-Ford sensors) • Over-repair (replacing the whole sensor vs replacing a valve) Good Part Examples (Figures 41-44) Figure 41 Item Description 1 Undamaged valve stem 2 Undamaged ladder area/lid 3 Undamaged sensor body Figure 42 Item Description 1 Correct Ford Part Number 2 Undamaged Sensor Body Figure 43 Item Description 1 Pressure Port Not Obstructed 2 Undamaged Valve Stem Figure 44 Item Description 1 Undamaged Valve Stem 2 Undamaged Potting Non-Ford Part Examples (Chargebacks) Different colors. North American units all use black parts. (Figures 45-46) Figure 45 Figure 46 No Ford part number (Figures 47-48) Figure 47 Figure 48 Different shapes. NOTE: North American units all use either the Edison or the Faraday profile. (Figure 49) Figure 49 Aftermarket Branding. NOTE: This could include branding such as EzSensor, Redi, and Schrader (Figure 50) Figure 50 Sensor Damage Examples (Chargebacks) Damaged valve stems (Figures 51-54) Figure 51 Figure 52 Figure 53 Figure 54 Damage to the sensor body (Figures 55-56) Figure 55 Figure 56 Avoiding Chargebacks Wrong Part Details: Things To Look For: 1. Does the sensor build date make sense for the model year of the vehicle? For example, if the sensor was built in 2019, it would not make sense to see this on a vehicle that is newer than the date on the sensor. It should be fairly close to the vehicle's production date. 2. Does the part number match what is listed in the catalog? 3. Is the part the correct frequency? Unless it is a trailer sensor the frequency for North American vehicles should be 315 MHz. Wrong Part Returned: This is the most common chargeback when it comes to TPMS. A few ways to avoid being charged back for this can include: 1. Include the sensor ID, build date, and part number within the technician comments. This will make sure that the part attached to the 700 tag is the part that is returned. 2. Verify the correct sensor using the parts catalog or this document. Sending back an Edison sensor instead of a Faraday sensor will result in a chargeback and vice versa. 3. Include a second copy of the 700 tag in the shipping box/envelope if attaching to the outside package. 4. Do not return a sensor that was made in 2009 for a vehicle that was made in 2019, as an example. If the sensor is over a year old compared to the vehicle build date then it is highly likely it is the wrong part. 5. Do not send back non-Ford TPMS sensors or other Ford parts. 6. Do not send back 433 MHz sensors if the vehicle has over 1,000 miles. North American vehicles do not use this frequency (trailer TPMS does). Sensor Damaged: This is the second most common chargeback: 1. The easiest way to avoid being charged back for this is to properly dismount the tire. Also making sure to remove the sensor from the valve stem before attempting to remove the valve stem. 2. If a sensor is damaged, and it is not caused by the plant, then do not send it back. Plant damage is easily determined upon review. 3. Do not send back a sensor if the valve stem was damaged. 4. Any defacing or intentional damaging of the part will result in a chargeback. Over Repair: This is the third most common chargeback. Examples of this include: 1. Replacing the entire sensor kit for a leaky valve. Order the proper valve kit to replace the valve. 2. Replacing the entire sensor kit for a cracked or blemished wheel. 3. Replacing all 4 sensors due to a BCM or RTM issue. 4. Replacement BCMs do not have the TPMS IDs stored in them. Non-functional RTMs will cause TPMS faults. © 2025 Ford Motor Company All rights reserved. NOTE: This information is not intended to replace or supersede any warranty, parts and service policy, workshop manual (WSM) procedures or technical training or wiring diagram information.

- 1 reply

-

- 3

-

-

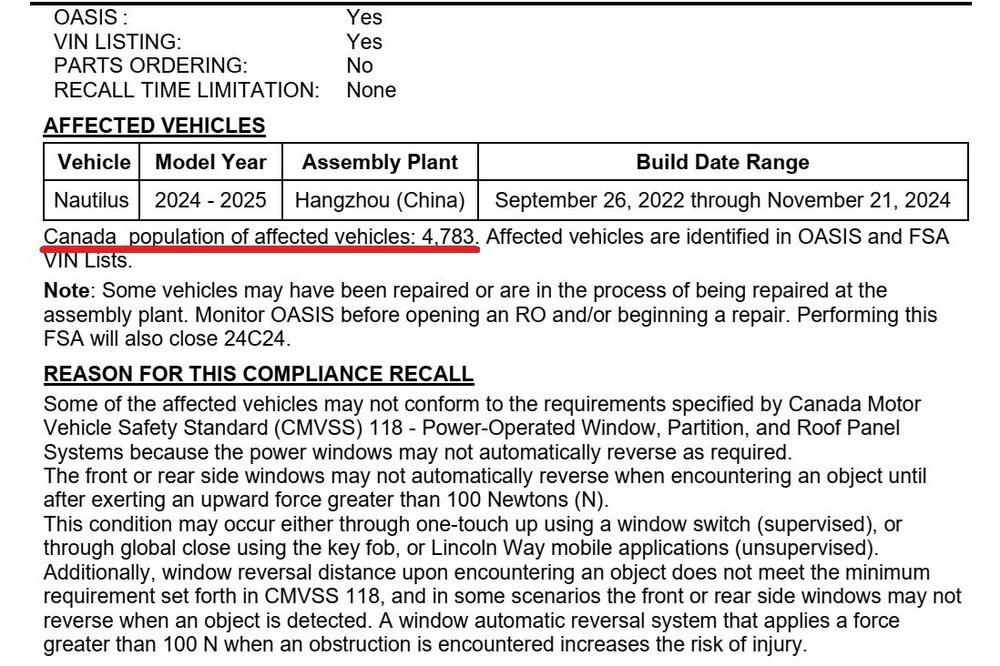

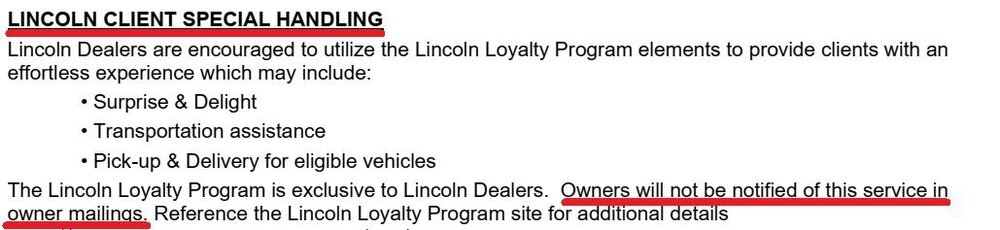

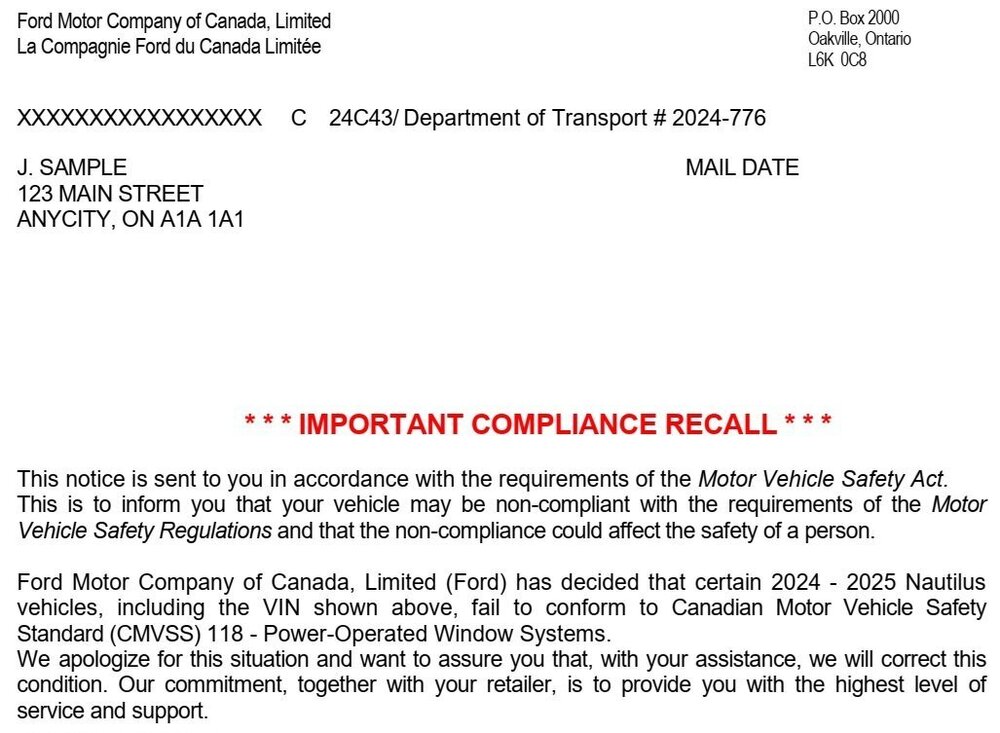

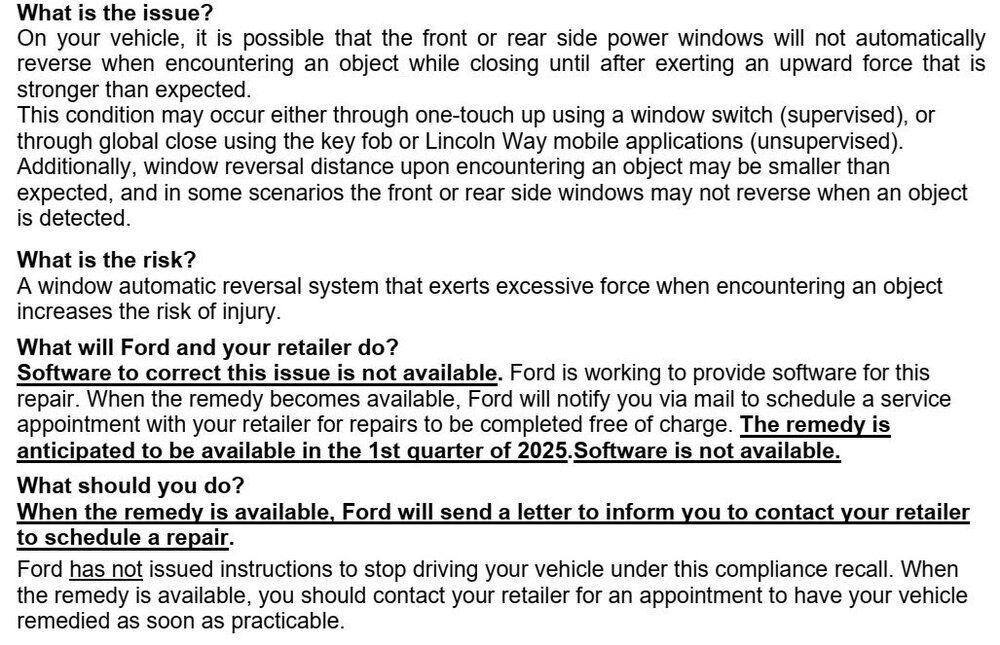

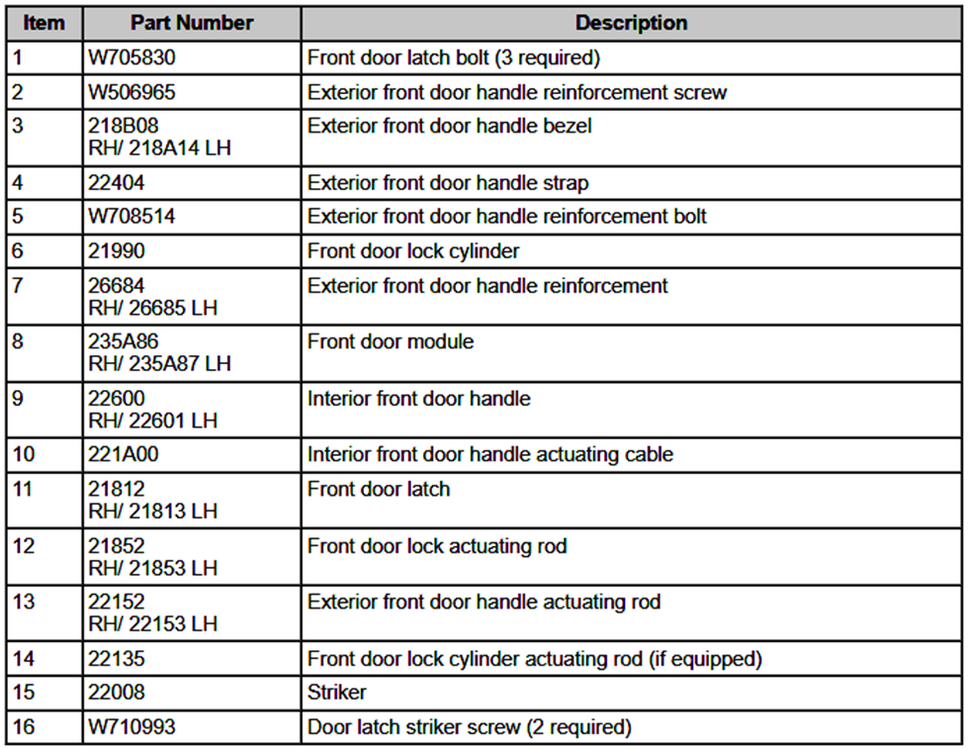

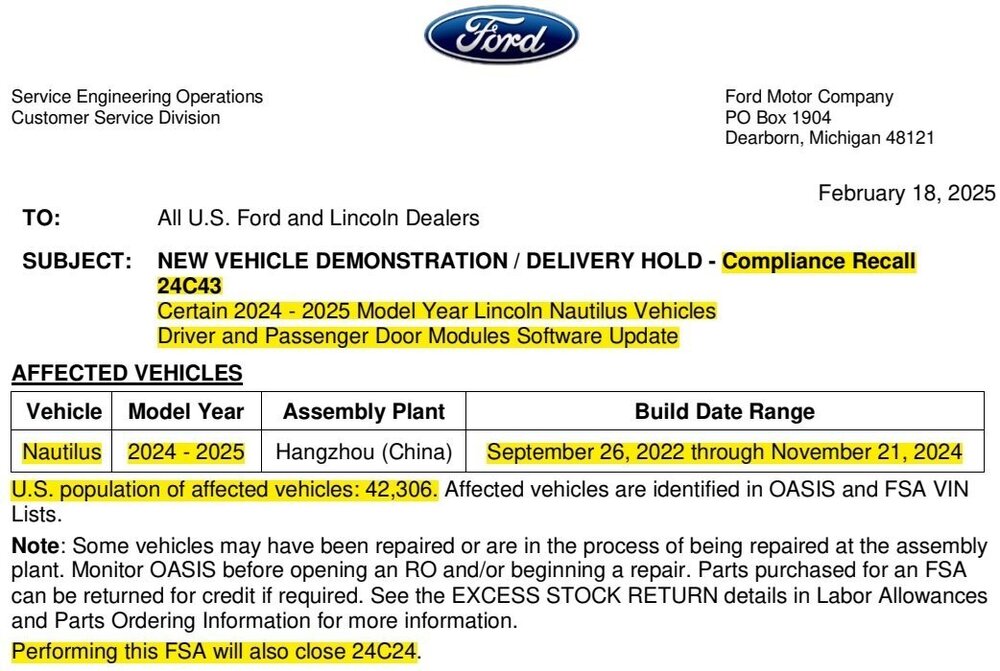

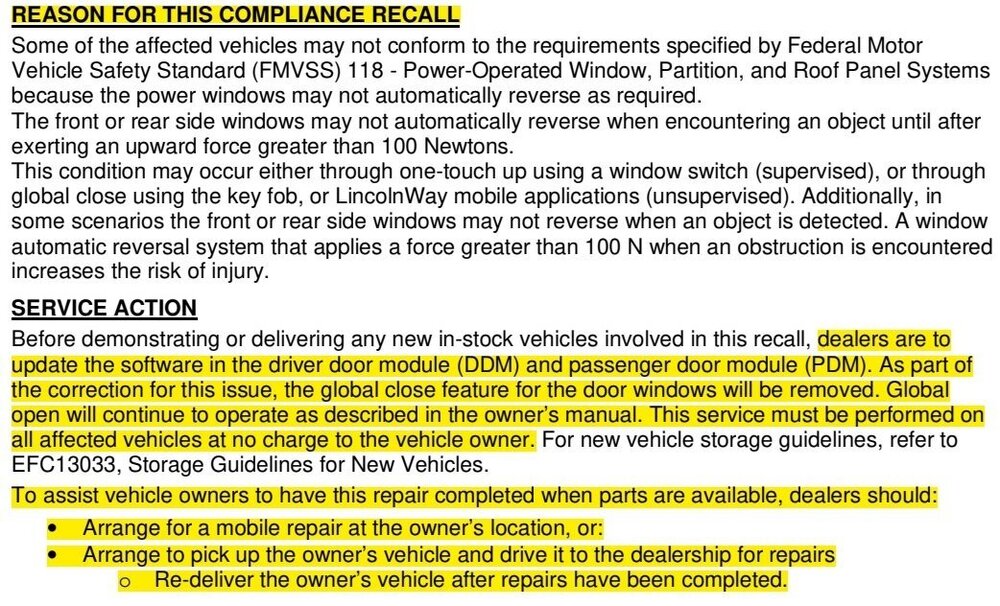

Compliance Recall 24C24 has been amended by Compliance Recall 24C43, which expands the Build Dates of affected units to include certain 2025 Nautilus vehicles. For more information, please see... Compliance Recall 24C43 - Advance Notice to Dealers - Certain 2024-2025 Nautilus - Driver and Passenger Door Modules Software Update - USA & Canada

-FillerPlugONLY.thumb.jpg.909f0bcf4eef17868eb2a4ad32637852.jpg)

-HeaterPwr-GndSuppliedViaRainSensorConectorC914Pins13-WiringDiagram-2019Edge.thumb.jpg.0684fb3d51c7ec4fbeb834cb56b733e0.jpg)