Haz

Edge Member-

Posts

1,568 -

Joined

-

Last visited

-

Days Won

435

Content Type

Profiles

Forums

Gallery

Everything posted by Haz

-

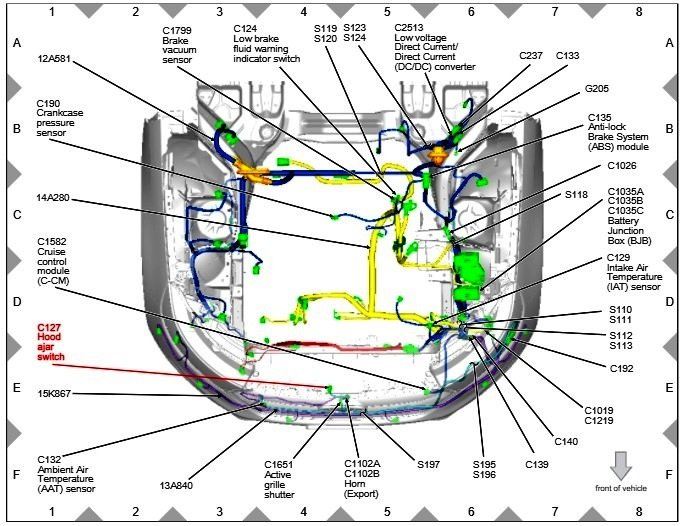

Below is Hood Ajar Switch connector location diagram and PDF download links to relevant sections of 2018 Edge Workshop Manual, which also states... The hood ajar switch is part of the hood latch and not serviceable separately. Good luck! Hood Latch-Hood Ajar Switch Connector Removal and Installation - 2018 Edge Workshop Manual.pdf Hood Ajar Switch Connector C127 Details - 2018 Edge Workshop Manual.pdf

-

Ambient Air Temp (AAT) Sensor Location?

Haz replied to Troger's topic in Interior, A.C., Heat, Interior Trim

Below are PDF download links to relevant sections from the 2018 Edge Workshop Manual... Ambient Air Temperature Sensor Removal and Installation - 2018 Edge Workshop Manual.pdf Front Bumper Cover Removal and Installation - 2018 Edge Workshop Manual.pdf System operation description... Outside Air Temperature The Ambient Air Temperature (AAT) sensor is hardwired to the PCM through separate input and return circuits. The PCM provides a reference voltage to the Ambient Air Temperature (AAT) sensor and monitors the change in voltage resulting from changes in resistance as determined by outside air temperature. The PCM sends the ambient air temperature data to the GWM through the HS-CAN1 . The GWM sends the ambient air temperature message to the HVAC (part of the FCIM ) over the MS-CAN . The FCIM filters the data and sends the ambient air temperature filtered data back to the GWM over the MS-CAN . The GWM sends the ambient air temperature filtered message to the IPC over the HS-CAN3 . The FCIM is programmed to update the messaged outside temperature data at different rates depending on several criteria to prevent false temperature displays due to a condition known as heat soaking. Heat soaking is where the outside air temperature is hotter in the location of the Ambient Air Temperature (AAT) sensor than the actual outside air temperature. The outside air temperature display update strategy requires a starting temperature to update from. This starting temperature is controlled based on the length of time the engine is off and the engine temperature. When the engine has been off for longer than 6 hours, the update strategy begins with the unfiltered ambient air temperature input to the PCM . If the engine has been off for less than 6 hours, and the engine coolant temperature is less than 49° C (120° F), the update strategy begins with the filtered ambient air temperature equal to the unfiltered ambient air temperature. If the engine has been off for less than 6 hours, and the engine coolant temperature is greater than 49° C (120° F), the update strategy begins at the stored previous outside air temperature value. When the sensed outside temperature rises and the vehicle speed is above 33 km/h (21 mph), the outside air temperature display updates after approximately 90 seconds. As the vehicle speed increases, the outside air temperature display updates at a faster rate that is proportional to the increase in vehicle speed. Once the vehicle speeds exceeds 81 km/h (50 mph), the display updates without any delay. If the vehicle speed drops below 33 km/h (21 mph), the update delays reset. When the sensed outside temperature drops, the display updates more quickly following the drop experienced by the Ambient Air Temperature (AAT) sensor. Good luck! -

-

Interior Lights won't come on when Door Opens

Haz replied to twincam1450's topic in Interior, A.C., Heat, Interior Trim

The following descriptions of the interior lighting system come from relevant sections of the 2014 Edge Workshop Manual... Good luck! Interior Lighting – Description and Operation The interior lighting system consists of the following components: Interior/map lamps Puddle lamps Cargo lamp Front scuff plate lamps Vanity mirror lamps Glove compartment lamp (MKX) Instrument panel dimmer switch (integrated into the Front Lighting Control Module (FLM) ) Door ajar switches (integrated into the door latches) Liftgate ajar switch (integrated into the liftgate latch) (manual liftgate) Liftgate/Trunk Module (LTM) (power liftgate) Body Control Module (BCM) Ambient lighting harnesses with LEDs HVAC module (located under the instrument panel near the steering column) The interior lighting system consists of: Courtesy lamps Demand lamps Ambient lighting (if equipped) Battery Saver NOTE: Time-out is 1 minute if the vehicle has less than 80 km (50 miles). To save battery voltage, the BCM provides automatic shut-off of the courtesy and demand lamps after a time-out period when the ignition is off. A timer in the BCM starts when any of the following occur: the ignition changes to off any door or liftgate becomes ajar while the ignition is off an UNLOCK button of the Remote Keyless Entry (RKE) transmitter is pressed while the ignition is off a valid keypad code is entered while the ignition is off the instrument panel dimmer switch is used to turn the courtesy lamps on while the ignition is off When 10 minutes have elapsed, the BCM automatically shuts off voltage to the lamps. The timer restarts (voltage is restored if the BCM is in battery saver mode) if any of the following occurs: the ignition changes out of off any door or liftgate becomes ajar the UNLOCK button of the Remote Keyless Entry (RKE) transmitter is pressed a valid keypad code is entered the instrument panel dimmer switch is pressed Courtesy Lamps The courtesy lamps subsystem consists of the door ajar switches (integrated into the door latches), the interior lamps, the cargo lamp, the puddle lamps, the scuff plate lamps, the FLM , and the BCM . Illuminated Entry The illuminated entry requests the dimmable backlighting, the parking lamps and the courtesy lamps to illuminate when the ignition is off and a door or liftgate is opened, the RKE transmitter UNLOCK button is pressed, or the vehicle is unlocked using the keyless entry keypad. If no doors are open, the illuminated entry requests the lamps off after 25 seconds have elapsed, the ignition switched out of off, the RKE transmitter LOCK button is pressed, or the vehicle is locked using the keyless entry keypad. Interior Lighting Delay The interior lighting delay feature provides temporary illumination of the dimmable backlighting, the parking lamps and the courtesy lamps after the doors are opened and then closed. The interior lighting delay feature keeps the lamps on for a period of 25 seconds after all the doors are closed. If during the 25 second delay time the BCM detects the ignition has been switched out of off, or if the vehicle is locked using the RKE transmitter or the keyless entry keypad, the lamp illumination is discontinued. Illuminated Exit The illuminated exit requests the dimmable backlighting, the parking lamps, and the courtesy lamps to illuminate for 25 seconds after all doors are closed and the ignition is turned off. The illuminated exit deactivates when the ignition transitions out of off, a door or liftgate becomes ajar, or 25 seconds have elapsed. Theater Lighting The theater lighting feature ramps-up the courtesy lamps over 0.7 second when courtesy lamp activation is requested. The theater lighting feature ramps-down the courtesy lamps over 1.7 seconds when interior lighting deactivation is requested by any feature other than the panic alarm or battery saver. Dark Car The dark car configuration disables the activation of the illuminated entry and illuminated exit features when active. The courtesy lamps can still be activated by the instrument panel dimmer switch. Demand Lamps The demand lamps subsystem consists of the map/reading lamps, the glove compartment lamp (MKX) and the vanity mirror lamps located in the visors. The BCM energizes the battery saver relay to supply voltage to the demand lamps when the battery saver feature is not active. Ambient Lighting The ambient lighting subsystem provides illumination to the center console cupholders, the storage bin, the door map pockets, the door pull handles, the door release handles, and the front and rear footwells for illuminated entry or when the ignition is in run with the parking lamps on. The ambient lighting is controlled using the touch screen display in the center of the instrument panel. When the illuminated entry feature is active, the ambient lighting defaults to a pre-set color and brightness setting. When all the doors are closed and the illuminated entry is no longer active, the ambient lighting returns to the last color and brightness setting that was set by the operator. The touch screen display is used to select one of 7 color combinations or turn the ambient lighting feature on or off. The ambient lighting system retains the last color setting and brightness between uses. For vehicles with memory seats, the ambient lighting color can also be set to correspond to the Driver 1 or Driver 2 settings. Interior Lighting – Testing and Diagnostics (Introduction) Principles of Operation The Body Control Module (BCM) controls all the interior lighting functions and timing by monitoring inputs from the following: door ajar switches liftgate ajar switch (manual liftgate) Liftgate/Trunk Module (LTM) (power liftgate) ignition state Front Lighting Control Module (FLM) Remote Keyless Entry (RKE) system vehicle speed The BCM turns off the courtesy lamps when the vehicle speed exceeds 15 km/h (9 mph) or 5 km/h (3 mph) for the puddle lamps, unless the courtesy lamps are turned on using the instrument panel dimmer switch (integrated into the FLM ). Interior Lamp Arbitrator The interior lamp arbitrator (programming within the BCM ) chooses between the interior lighting delay, the illuminated entry and exit, the battery saver, and the alarm flash processing to determine which feature has precedence of activating and deactivating the interior lamps. Ambient Lighting The HVAC module controls the ambient lighting system. When requested, the HVAC module provides voltage and ground to the LEDs. There are 3 LEDs (Edge) (red, blue and green) or 4 LEDs (MKX) (red, blue, green and white) housed within each LED assembly. By illuminating various color combinations, the LEDs are able to produce 7 different colors of ambient light. The HVAC module receives input from the Accessory Protocol Interface Module (APIM) and the Body Control Module (BCM) over the communication network for color and brightness settings. The display interface in the center of the instrument panel is used to cycle through different color variations or turn the ambient lighting feature on or off. The APIM communicates messages over the High Speed Controller Area Network (HS-CAN) to the Body Control Module (BCM) . The BCM gateways the messages to the HVAC module over the Medium Speed Controller Area Network (MS-CAN) . The HVAC module retains the last color and brightness setting between uses. Field-Effect Transistor (FET) Protection A Field-Effect Transistor (FET) is a type of transistor that, when used with module software, monitors and controls current flow on module outputs. The FET protection strategy prevents module damage in the event of excessive current flow. The BCM utilizes an FET protective circuit strategy for many of its outputs (for example, a headlamp output circuit). Output loads (current level) are monitored for excessive current (typically short circuits) and are shut down (turns off the voltage or ground provided by the module) when a fault event is detected. A short circuit DTC is stored at the fault event and a cumulative counter is started. When the demand for the output is no longer present, the module resets the FET circuit protection to allow the circuit to function. The next time the driver requests a circuit to activate that has been shut down by a previous short (FET protection) and the circuit is still shorted, the FET protection shuts off the circuit again and the cumulative counter advances. When the excessive circuit load occurs often enough, the module shuts down the output until a repair procedure is carried out. Each FET protected circuit has 3 predefined levels of short circuit tolerance based on the harmful effect of each circuit fault on the FET and the ability of the FET to withstand it. A module lifetime level of fault events is established based upon the durability of the FET . If the total tolerance level is determined to be 600 fault events, the 3 predefined levels would be 200, 400 and 600 fault events. When each tolerance level is reached, the short circuit DTC that was stored on the first failure cannot be cleared by a command to clear the continuous DTCs. The module does not allow this code to be cleared or the circuit restored to normal operation until a successful self-test proves that the fault has been repaired. After the self-test has successfully completed (no on-demand DTCs present), DTC U1000:00 and the associated DTC (the DTC related to the shorted circuit) automatically clears and the circuit function returns. When each level is reached, the DTC associated with the short circuit sets along with DTC U1000:00. These DTCs are cleared using the module on-demand self-test, then the Clear DTC operation on the scan tool (if the on-demand test shows the fault corrected). The module never resets the fault event counter to zero and continues to advance the fault event counter as short circuit fault events occur. If the number of short circuit fault events reach the third level, then DTCs U1000:00 and U3000:49 set along with the associated short circuit DTC. DTC U3000:49 cannot be cleared and the module must be replaced after the repair. The BCM FET protected output circuits for the interior lighting system are the interior courtesy lamp and puddle lamp output circuits. Inspection and Verification Verify the customer concern. Visually inspect for obvious signs of electrical damage. Visual Inspection Chart Electrical Body Control Module (BCM) fuse(s): 4 (10A) (demand lamps) 12 (15A) (courtesy lamps) Wiring, terminals or connectors Bulb(s) Interior lamp(s) Puddle lamp(s) Scuff plate lamp(s) Cargo lamp Glove compartment lamp Vanity mirror lamp(s) Instrument panel dimmer switch (integrated into the Front Lighting Control Module (FLM) ) -

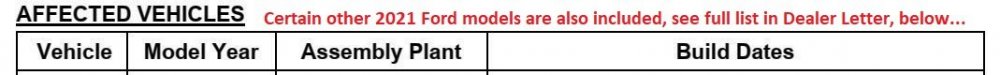

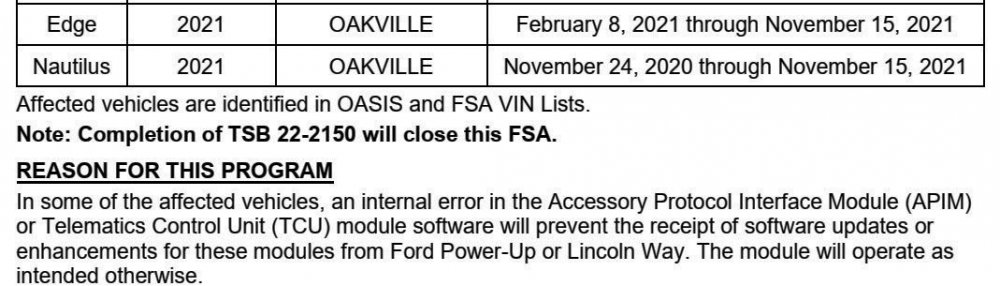

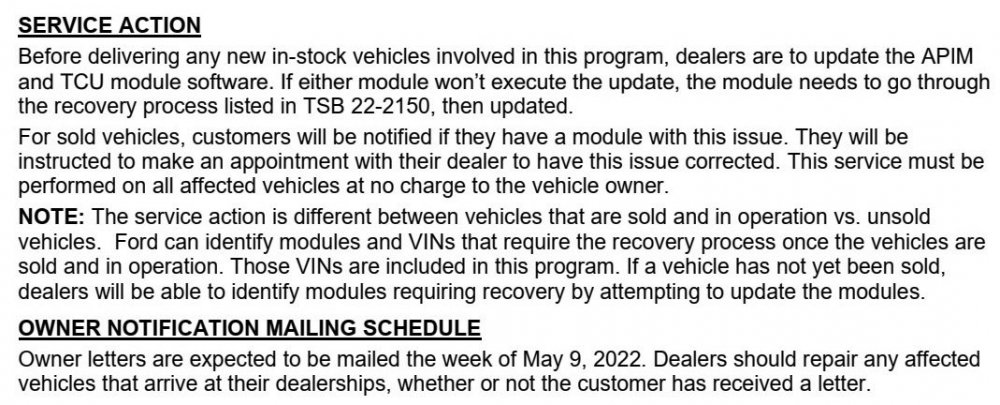

May 12 2022 RESOLVED: 2021 - 2022 Edge, APIM Software Update Failures RESOLVED- The Ford Technical Assistance Center and Ford IT teams are aware that due to server related concerns, APIM programming was failing with an error message stating “Procedure Unsuccesful - GetConfigDataFromGIVIS Modified Configuration data is missing from Ford server". This has been resolved.

-

Below are PDF download links to Crankcase Ventilation Tube Removal and Installation instructions from the 2019 Edge Workshop Manual and to Technical Service Bulletin 21-2340, relating to your Edge's issue. Despite your Edge's BTB warranty expiration occurring so very recently, discuss the TSB with your dealership's Service Department to see if they can get authorization to perform the TSB action, presuming your Edge's Build Date is within the TSB's date range. It may be covered under Engine Emissions warranty. The Workshop Manual section will familiarize you with the required task. Good luck! TSB 21-2340 - 2.0L EcoBoost - Illuminated MIL With DTC P04DB - Built On Or Before 22-Aug-2019.pdf Crankcase Ventilation Tube - Removal and Installation - 2019 Edge Workshop Manual.pdf

-

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

So, they come on with the parking lights, or only when using the toggle switch? Congrats on your perseverance, regardless. Good luck! -

Since you've been to the Sync Update Download Page, your thumb drive format is FAT32 for pre-Version 3 Sync system update? If you do not have Navigation, you could use an SD card for your audio files. I use a 2 GB card formatted FAT32 for mp3 files with no issues. Good luck!

-

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

-

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

It is possible the SE chrome-finish grille has been dipped or painted to mimic the Sport-model appearance. Good luck! -

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

Do your Edge's wheels match those in the image you posted? If you are comfortable providing me the VIN via the Forum's Message system, I'll look it up in Ford's OASIS information system, which is used by dealership Service technicians. Good luck! -

Just noticed this on Ford's Professional Technician System bulletin board... May 9 2022 2021 - 2022 Edge, APIM Software Update Failures The Ford Technical Assistance Center and Ford IT teams are aware that due to server related concerns, APIM programming is failing with an error message stating “Procedure Unsuccesful - GetConfigDataFromGIVIS Modified Configuration data is missing from Ford server". Monitor PTS for updates. If any updates are provided, I'll pass them along. Good luck!

-

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

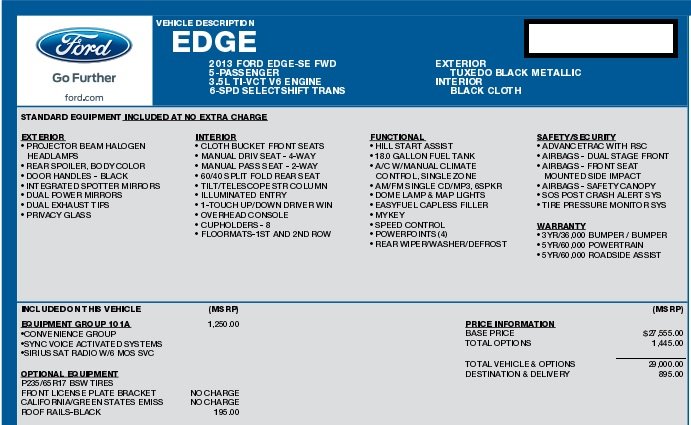

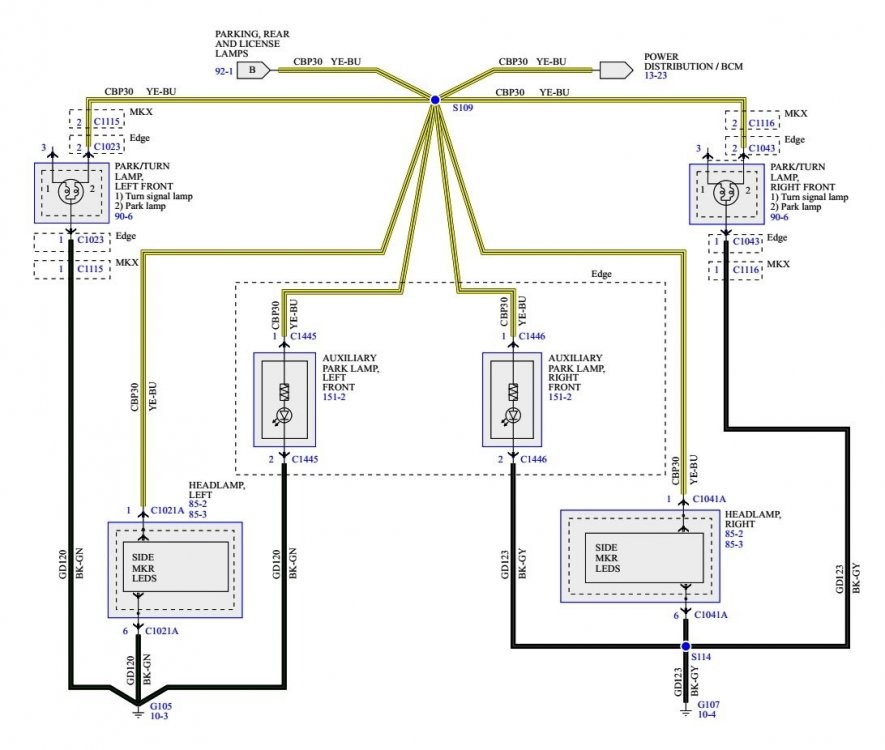

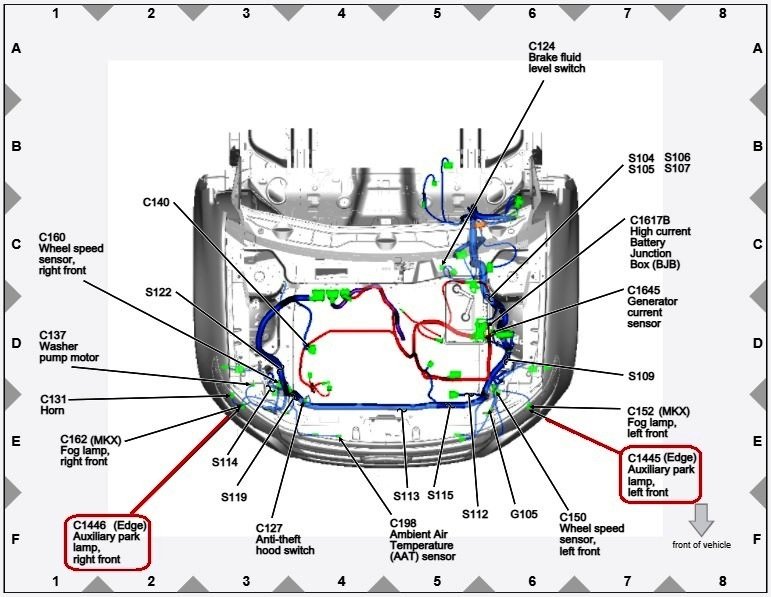

Sympathies to you on your back problems. Back pain has been rare for me, but I appreciate how debilitating it can be. As you're likely aware, the image you shared is a Sport model with its blackout grille, 22-inch wheels, and the LED auxiliary parking lamps as standard equipment. It's worth noting that factory-installed auxiliary parking lamps are wired into the same power-distribution circuit as the front parking lamps & side marker lamps, as well as the rear parking & license plate lamps, per (1004ron's-encouraged) wiring diagram from the 2013 Edge Workshop Manual, included below as an image and a PDF via download link below... On the off-chance that your SE Edge's wiring includes unused plugs for Ford-supplied LED auxiliary parking lamp assemblies. descriptions of wiring connectors used for the left & right side auxiliary parking lamps are included below as PDF download links... If you prefer the installed vertical LED light strips to be on whenever your Edge's parking lamps are lit, you could tap into the front parking/side marker wiring to supply them power. If you prefer to use them as Daytime Running Lights (DRLs), you can troubleshoot the toggle switch circuit, presuming that's how the previous owner installed them to operate. Or you could have both, by tapping into the front parking/side marker wiring to power up the installed LED lights whenever your Edge's parking/tail lamps are lit, and then gain DRLs by asking your dealer to activate your Edge's factory-supplied capability, or do-it-yourself if you or a friend are fluent Forscan-user(s), with the benefit as described in the 2013 Edge Workshop Manual... Daytime Running Lamps (DRL) NOTE: The Daytime Running Lamps (DRL) are a programmable parameter for this vehicle. For vehicles with halogen headlamps: Daytime Running Lamps (DRL) can be enabled/disabled using the BCM Programmable Parameter, DRL Type. the factory selected DRL system operates the low beam headlamps at a reduced intensity. when enabling the DRL using a scan tool, two modes of operation can be selected. The low beam headlamps will illuminate at a reduced intensity (halogen headlamps) or the front turn lamps will illuminate continuously (not flashing) at full intensity. For vehicles with High Intensity Discharge (HID) headlamps: NOTICE: Do not enable Low Beams DRL mode If the vehicle is equipped with High Intensity Discharge (HID) headlamps. If Low Beams DRL mode is enabled, damage to the headlamp ballast may occur. Daytime Running Lamps (DRL) can be enabled/disabled using the BCM Programmable Parameter, DRL Type. the factory selected DRL system operates the front turn lamps illuminate continuously (not flashing) at full intensity. when enabling the DRL using a scan tool, only one mode of operation should be selected. The front turn lamps will illuminate continuously (not flashing) at full intensity. The DRL are activated when the following conditions are met: the ignition is in RUN the headlamps have not been turned on by the autolamp system or the headlamp switch the transmission is not in park Good luck! Auxiliary Parking Lamps Wiring Diagram - 2013 Edge Workshop Manual.pdf Auxiliary Parking Lamp, Right Front C1446 Wiring Connector - 2013 Edge Workshop Manual.pdf Auxiliary Parking Lamp, Left Front C1445 Wiring Connector - 2013 Edge Workshop Manual.pdf -

LED strip lights 2013 Edge SE

Haz replied to BraddB's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

The 2013 Edge Sourcebook lists "Parking lamps — supplemental, light-emitting diode (LED)" as standard on SEL trim level, but I do not find any mention of that feature for SE. The SE Convenience Package 101A includes "Autolamp automatic on/off headlamps", but no other exterior lighting feature. Online photos of 2013 SE Edges show a black plastic filler panel where the factory-installed supplemental parking lamp/LED strip is on SEL/Limited/Sport models, as shown in the below image... The LED strips could be actual Ford parts, or aftermarket, installed by a previous owner, and now unsuccessfully controlled by that toggle switch. Look for non-standard wiring and see if what's connected to the LED strips inside the front bumper cover matches the wiring connected to the toggle switch. Good luck! -

I appreciate your photo of the parking brake equalizer arrangement, which the 2010 Edge Workshop Manual describes as... The front parking brake cable is coupled to the LH rear parking brake cable and conduit which is coupled to the RH rear parking brake cable. The parking brake cable and conduits actuate the parking brake levers, engaging the parking brake shoes with the parking brake drum-in-hat assembly. To address your additional question, I lifted the rear end of our 2015 AWD MKX, which is a GEN 1 vehicle like yours, With both rear tires off the floor, and regardless of the transmission being in either Park or Neutral, each wheel rotates freely while the other-side.wheel rotates in the opposite direction, without any noticeable brake pad drag. Good luck!

-

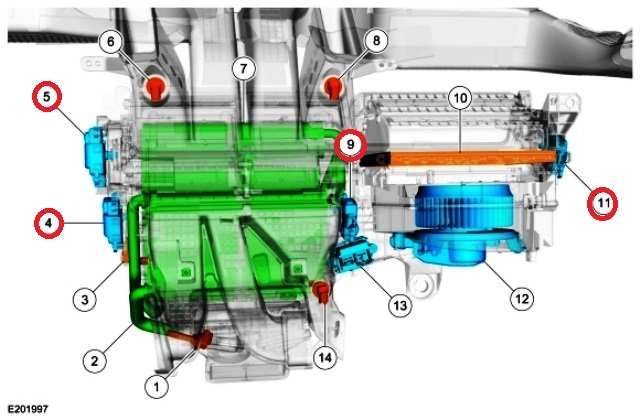

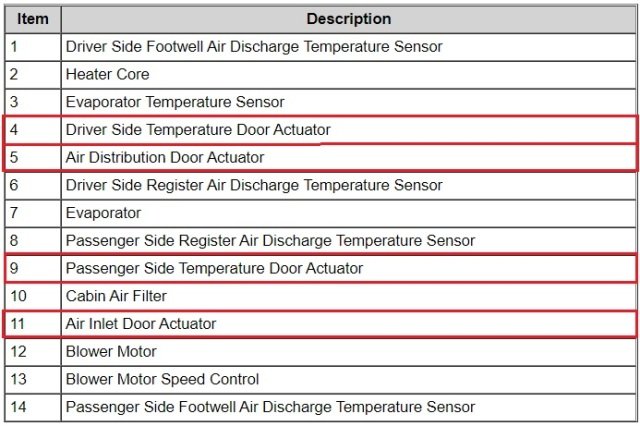

Just to clarify your question, in the case of hot air output on left side and cold air output on right side, is desired goal AC/cold air output temperature on both sides? The following illustration and component listing from the 2015 Edge Workshop Manual shows the location and function of the four actuators you mention... Good luck!

-

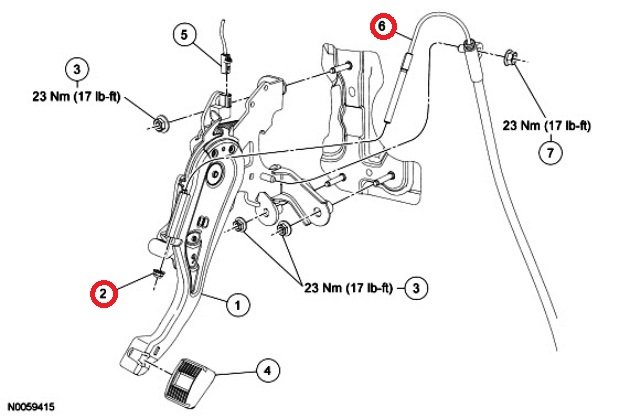

Sorry for inducing information overload with the full set of documents, which hopefully may be helpful to a future reader. You will find In the previously posted Parking Brake Adjustment Workshop Manual PDF document, that Ford immediately specifies that adjustment should be applied equally at both cable-end locations -- at the interior parking brake pedal and at the under-body equalizer. I can only speculate that splitting the total adjustment across both ends of the forward cable may increase its usable life. This illustration shows the location of the interior adjustment nut (2)... Equal turns to the interior pedal adjustment nut and to the under-body equalizer adjustments nut, until you verify a properly holding (and releasing) parking brake by applying the parking brake three times. Good luck!

-

From the 2022 Edge Workshop Manual... Manual APIM Reset Simultaneously press and hold the POWER button (in the middle of the volume button) and the RIGHT SEEK button on the audio controls panel to reboot the APIM . As the APIM reboot begins, the display unit turns black before the startup sequence begins. Good luck!

-

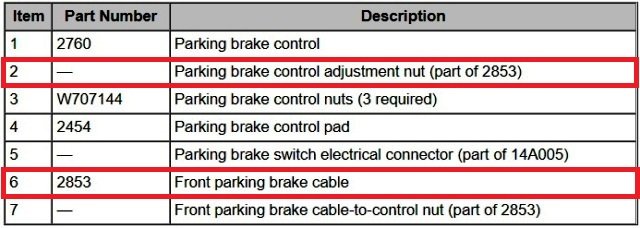

2013 ford edge AWD rear suspension torque specs

Haz replied to thegoose's topic in Brakes, Chassis & Suspension

Below is an illustration of the rear suspension showing the Tow Link and its mounting bolt torque values, as well as PDF download links to relevant sections of the 2013 Edge Workshop Manual... Good luck! Rear Suspension Toe Link Removal and Installation - 2013 Edge Workshop Manual.pdf Rear Suspension Torque Specifications - 2013 Edge Workshop Manual.pdf Suspension General Procedures - Rear Toe Adjustment - 2013 Edge Workshop Manual.pdf -

The following is from relevant sections of the 2022 Edge Workshop Manual... The Outside Air Temperature Display Is Inoperative or Incorrect Outside Air Temperature - Normal Operation The Ambient Air Temperature (AAT) sensor is hardwired to the PCM through separate input and return circuits. The PCM provides a reference voltage to the Ambient Air Temperature (AAT) sensor and monitors the change in voltage resulting from changes in resistance as determined by outside air temperature. The PCM sends the ambient air temperature data to the GWM through the HS-CAN1 . The GWM sends the ambient air temperature message to the HVAC module over the MS-CAN . The HVAC module filters the data and sends the ambient air temperature filtered data back to the GWM over the MS-CAN . The GWM sends the ambient air temperature filtered message to the IPC over the HS-CAN3 . The HVAC module is programmed to update the messaged outside temperature data at different rates depending on several criteria to prevent false temperature displays due to a condition known as heat soaking. Heat soaking is where the outside air temperature is hotter in the location of the Ambient Air Temperature (AAT) sensor than the actual outside air temperature. The outside air temperature display update strategy requires a starting temperature to update from. This starting temperature is controlled based on the length of time the engine is off and the engine temperature. When the engine has been off for longer than 6 hours, the update strategy begins with the unfiltered ambient air temperature input to the PCM . If the engine has been off for less than 6 hours, and the engine coolant temperature is less than 49° C (120° F), the update strategy begins with the filtered ambient air temperature equal to the unfiltered ambient air temperature. If the engine has been off for less than 6 hours, and the engine coolant temperature is greater than 49° C (120° F), the update strategy begins at the stored previous outside air temperature value. When the sensed outside temperature rises and the vehicle speed is above 33 km/h (21 mph), the outside air temperature display updates after approximately 90 seconds. As the vehicle speed increases, the outside air temperature display updates at a faster rate that is proportional to the increase in vehicle speed. Once the vehicle speeds exceeds 81 km/h (50 mph), the display updates without any delay. If the vehicle speed drops below 33 km/h (21 mph), the update delays reset. When the sensed outside temperature drops, the display updates more quickly following the drop experienced by the Ambient Air Temperature (AAT) sensor. Outside Air Temperature - Fault Conditions If the air ambient temperature message is missing or invalid for less than 5 seconds, the IPC defaults the outside air temperature display to the last temperature reading, based upon the last message received. If the air ambient temperature message is missing or invalid for 5 seconds or longer from the PCM , the IPC displays all dashes (- - ) in the outside air temperature display area. Possible Sources Communication concern Ambient Air Temperature (AAT) sensor input to the PCM GWM concern HVAC module concern You mention that the Outside Air Temperature value is correctly displaying on the right side message center of your Instrument Panel Cluster, which suggests the AAT sensor, Powertrain Control Module, and Gateway Module communication to the Instrument Panel Cluster is good, but that the communication of the Outside Air Temperature value to the Center Stack Touch Screen is missing. Given that your Edge has just 400 miles on it, and the disappearance occurred suddenly, it's possible a wiring connector is not fully seated and the proper data communication to the Center Stack Touch Screen is now interrupted. You also mention the Settings menu does not allow you to change from Metric measurement values to English measurement values, though you don't mention if you're attempting this using the Center Stack Touch Screen, or if any-or-all data values in the display are expressed in Metric measurement. If indeed you're using the Touch Screen to attempt that Settings change, the the lack of success, as you say, may be related to an apparent communications problem, possibly caused by a not-fully-seated electrical connector. As a check on System function, try using your Edge's steering wheel controls to access the Settings menu in the right hand side message center of the Instrument Panel Cluster to change the measurement values from English to Metric and back to English for you IPC. Overcome your (understandable) dread of returning your Edge to the dealership, and give your sales rep a call to see if he-or-she can facilitate scheduling a more prompt Service appointment and loaner-vehicle provision, on your behalf. Your sales rep has a vested interest in you remaining a satisfied dealership customer. Also keep in mind, they are no more happy than you, to be correcting a warranty issue so soon after a vehicle's delivery to its new owner. I checked OASIS to see if any Technical Service Bulletin regarding you concern showed up, but I found none, though I only used model year in my request, and searching by VIN is a more sure method. Good luck!

-

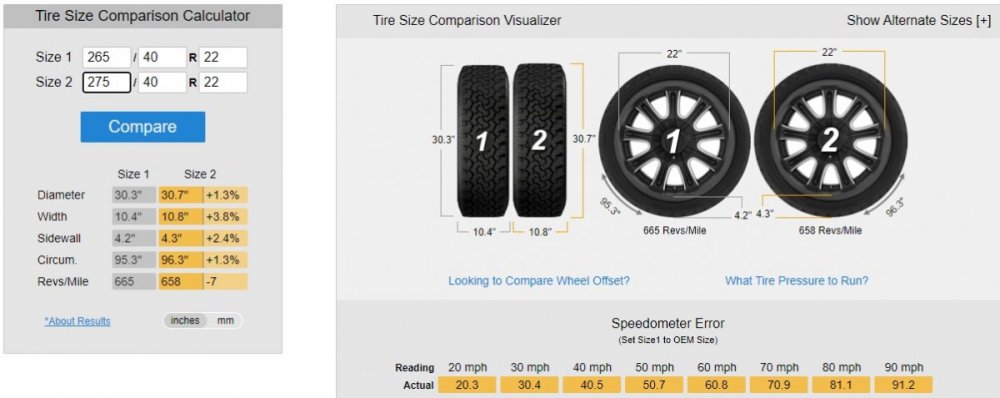

You would do best to follow Pirelli's wheel width recommendation for the specific model of 275/40R22 tire you are contemplating to buy. Many Pirelli tire models show the 9-inch wheel width on your Edge Sport as being the minimum acceptable size for 275/40R22, while a few other Pirelli tire models recommend 10-to-11/12-inch wheel widths. Lincoln provides 9 1/2-inch wide rims for the 275/40R22 tires on its Aviator, which presumably are the minimum for the OEM tire manufacturer. The Tiresize website provides these general statements about your Edge Sport's OEM tire size and the upsized tire you are considering, as well as the comparative graphic, below... Good luck! 265/40R22 tires have a diameter of 30.3", a section width of 10.4", and a wheel diameter of 22". The circumference is 95.3" and they have 665 revolutions per mile. Generally they are approved to be mounted on 9-10.5" wide wheels. Specs may vary by manufacturer 275/40R22 tires have a diameter of 30.7", a section width of 10.8", and a wheel diameter of 22". The circumference is 96.3" and they have 658 revolutions per mile. Generally they are approved to be mounted on 9-11" wide wheels. Specs may vary by manufacturer

-

Below are PDF download links to sections of the 2010 Edge/MKX Workshop Manual relating to the Parking Brake system... Good luck! Parking Brake and Actuation - Diagnosis and Testing - 2010 Edge Workshop Manual.pdf Parking Brake Cable Adjustment - 2010 Edge Workshop Manual.pdf Parking Brake Cable - Front, Removal and Installation - 2010 Edge Workshop Manual.pdf Parking Brake Cable - Rear LH, Removal and Installation - 2010 Edge Workshop Manual.pdf Parking Brake Cable - Rear RH, Removal and Installation - 2010 Edge Workshop Manual.pdf Parking Brake Shoes - Removal and Installation - 2010 Edge Workshop Manual.pdf Brake Disc - Removal and Installation - 2010 Edge Workshop Manual.pdf Parking Brake and Actuation - Torque Specifications - 2010 Edge Workshop Manual.pdf

-

Rear/right turn signal issue

Haz replied to Lenny's topic in Glass, Lenses, Lighting, Mirrors, Sunroof (BAMR), Wipers

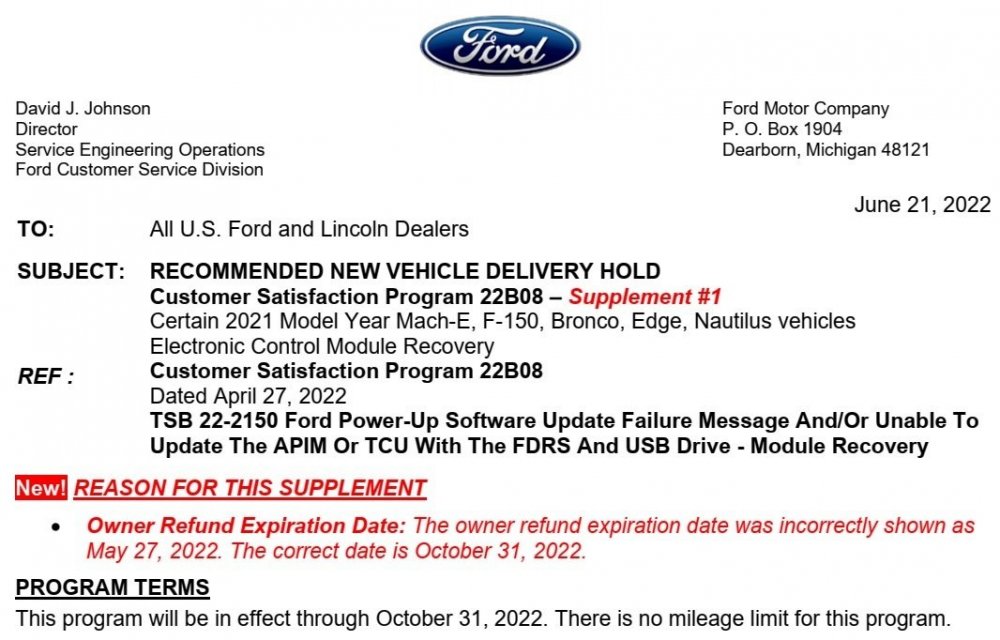

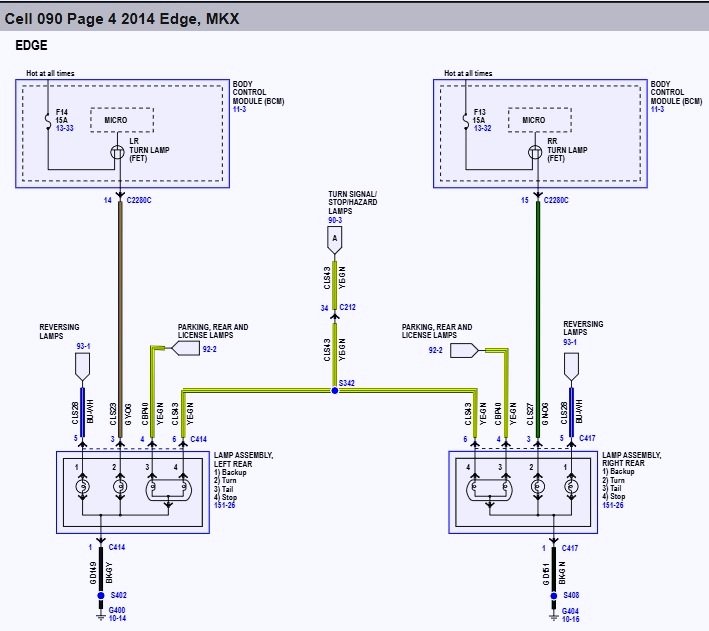

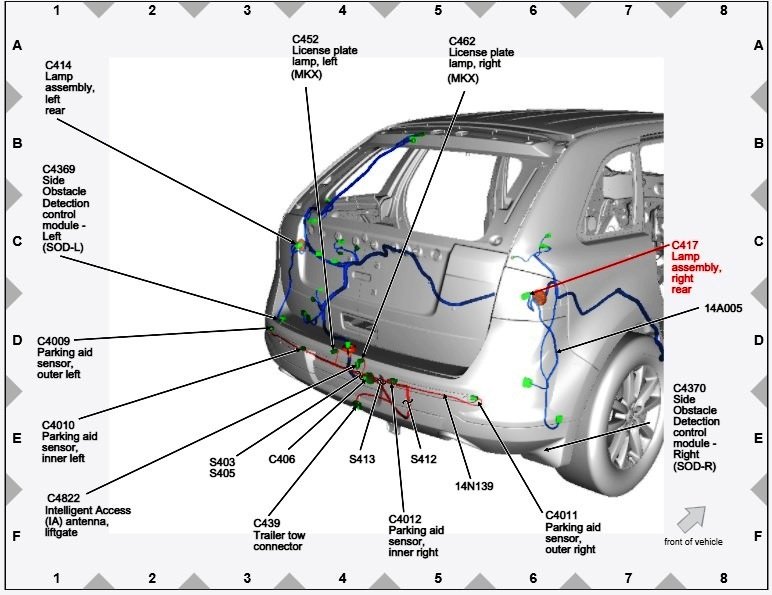

To assist you toward resolution of your Edge's right rear turn signal problem, below are PDF download links to Turn Signal and Hazard Lamps Diagnosis and Testing Procedures, and other related sections from the 2014 Edge Workshop Manual, as well as wiring and connector location diagrams as images... Good luck! Turn Signal and Hazard Lamps Diagnosis and Testing Procedures - 2014 Edge Workshop Manual.pdf Right Rear Stop-Tail Light Connector C417 - Wiring-Circuit Legend - 2014 Edge Workshop Manual.pdf Body Control Module (BCM) Connector C2280C Wiring-Circuit Legend - 2014 Edge Workshop Manual.pdf Instrument Panel - Exploded View - 2014 Edge Workshop Manual.pdf Body Control Module (BCM) Removal and Installation - 2014 Edge Workshop Manual.pdf Module Configuration Includes BCM - 2014 Edge Workshop Manual.pdf Body Control Module (BCM) - Principles of Operation The Body Control Module (BCM) controls various systems by monitoring inputs from switches, sensors and messages sent from other modules. The BCM activates outputs based on the inputs received. For example, the Front Lighting Control Module (FLM) monitors the headlamp switch and transmits the headlamp switch position to the BCM over the network. Based on this input, the BCM may provide voltage to the exterior lamps. Field-Effect Transistor (FET) Protection A Field-Effect Transistor (FET) is a type of transistor that, when used with module software, monitors and controls current flow on module outputs. The FET protection strategy prevents module damage in the event of excessive current flow. The BCM utilizes an FET protective circuit strategy for many of its outputs (for example, a headlamp output circuit). Output loads (current level) are monitored for excessive current (typically short circuits) and are shut down (turns off the voltage or ground provided by the module) when a fault event is detected. A short circuit DTC is stored at the fault event and a cumulative counter is started. When the demand for the output is no longer present, the module resets the FET protection to allow the circuit to function. The next time the driver requests a circuit to activate that has been shut down by a previous short (FET protection) and the circuit is still shorted, the FET protection shuts off the circuit again and the cumulative counter advances. When the excessive circuit load occurs often enough, the module shuts down the output until a repair procedure is carried out. Each FET protected circuit has 3 predefined levels of short circuit tolerance based on the harmful effect of each circuit fault on the FET and the ability of the FET to withstand it. A module lifetime level of fault events is established based upon the durability of the FET . If the total tolerance level is determined to be 600 fault events, the 3 predefined levels would be 200, 400 and 600 fault events. When each tolerance level is reached, the short circuit DTC that was stored on the first failure cannot be cleared by the clear the CMDTCs command. The module does not allow this code to be cleared or the circuit restored to normal operation until a successful self-test proves that the fault has been repaired. After the self-test has successfully completed (no on-demand DTCs present), DTC U1000:00 and the associated DTC (the DTC related to the shorted circuit) automatically clears and the circuit function returns. When each level is reached, the DTC associated with the short circuit sets along with DTC U1000:00. These DTCs are cleared using the module on-demand self-test, then the Clear DTC operation on the scan tool (if the on-demand test shows the fault corrected). The module never resets the fault event counter to zero and continues to advance the fault event counter as short circuit fault events occur. If the number of short circuit fault events reach the third level, then DTCs U1000:00 and U3000:49 set along with the associated short circuit DTC . DTC U3000:49 cannot be cleared and the module must be replaced after the repair. Gateway Function The BCM acts as a gateway module by receiving information in one format and transmitting it to other modules using another format. For example, the BCM receives the vehicle speed data from the PCM over the High Speed Controller Area Network (HS-CAN) , converts the data into a Medium Speed Controller Area Network (MS-CAN) message and sends (gateways) the message to other network modules such as the HVAC module and the Audio Front Control Module (ACM) . This enables network communication between modules that do not communicate using the same network (HS-CAN or MS-CAN ). -

FordeEdge 2011 AC blower turns on and Off

Haz replied to TARiQ's topic in Interior, A.C., Heat, Interior Trim

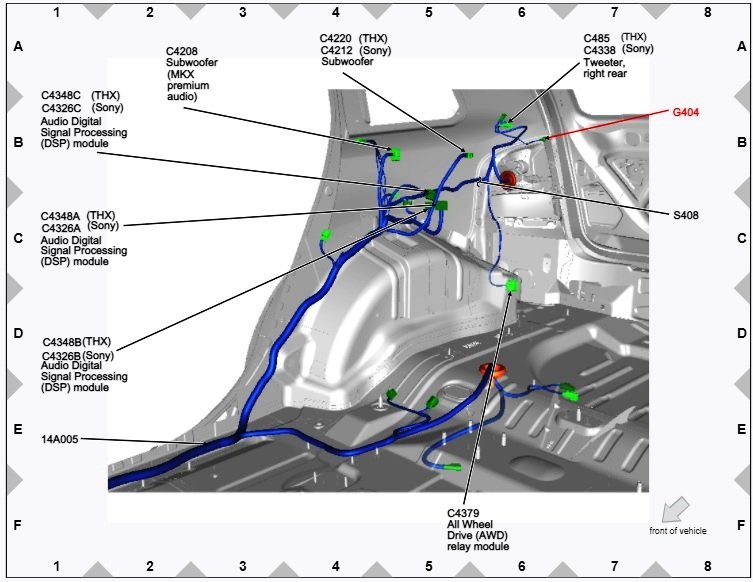

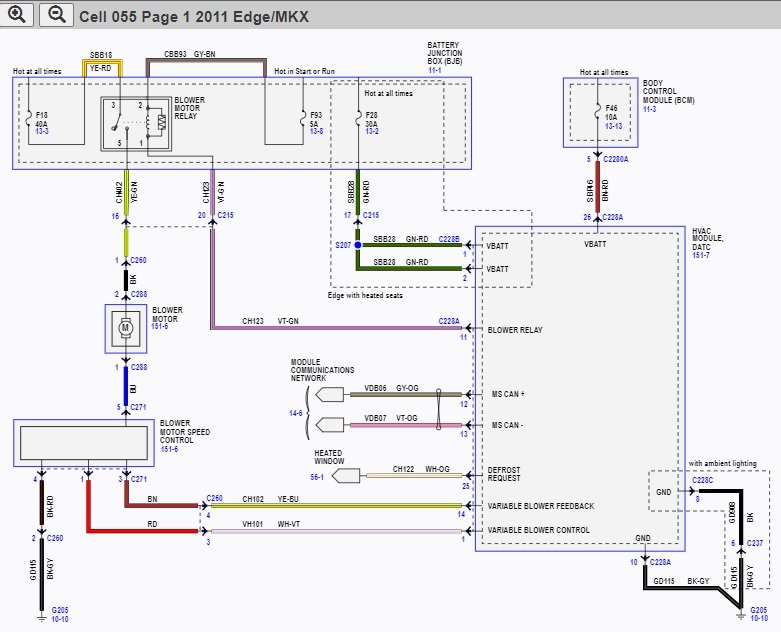

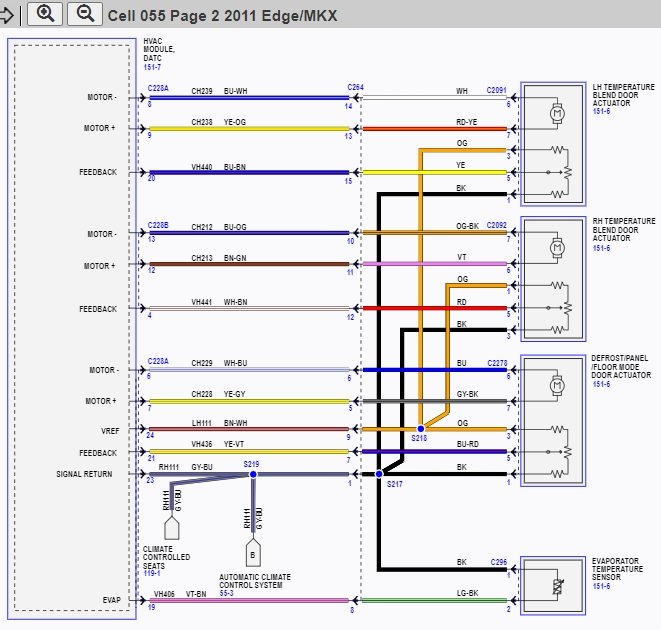

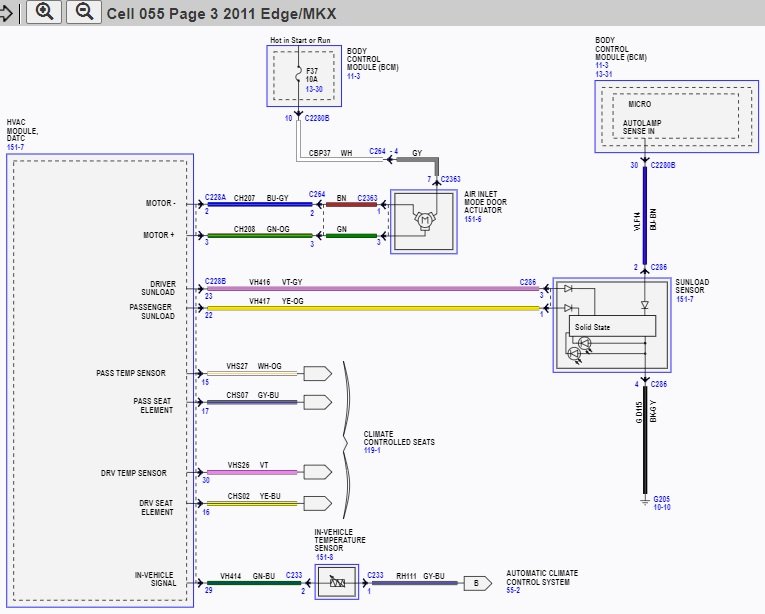

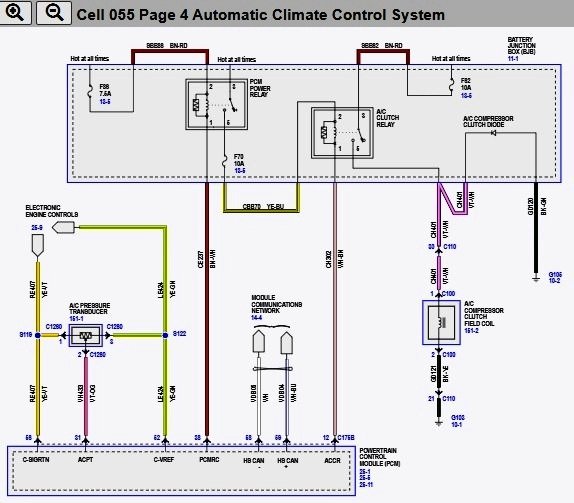

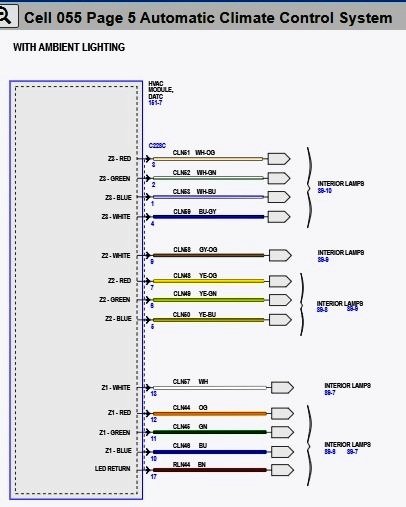

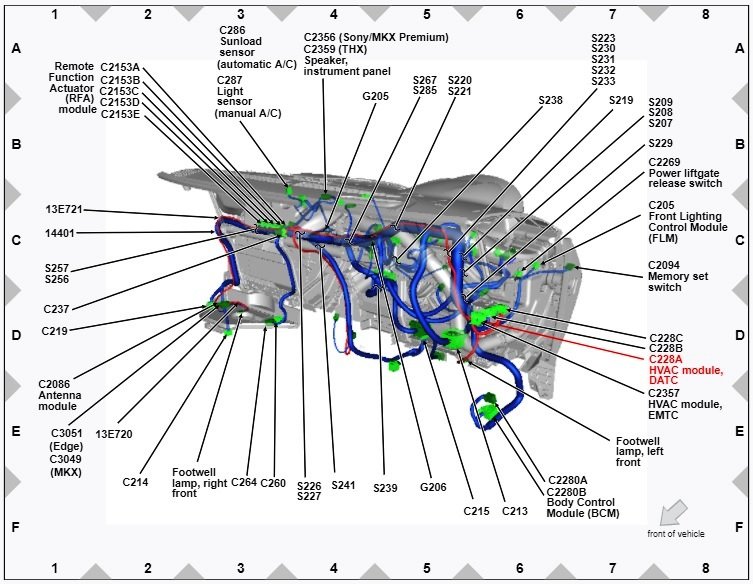

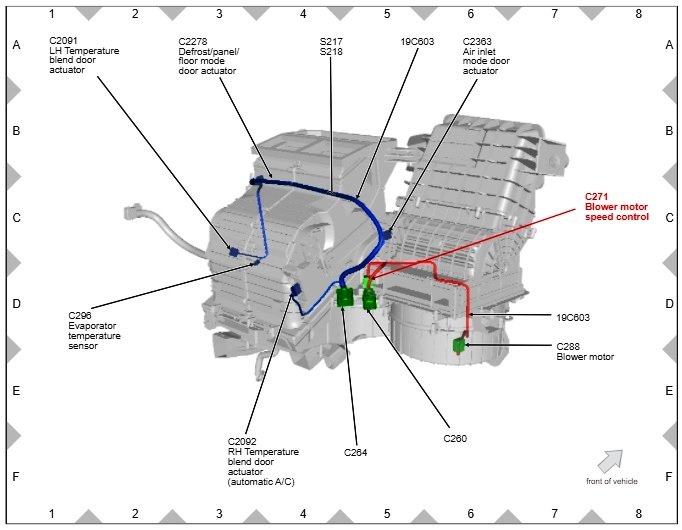

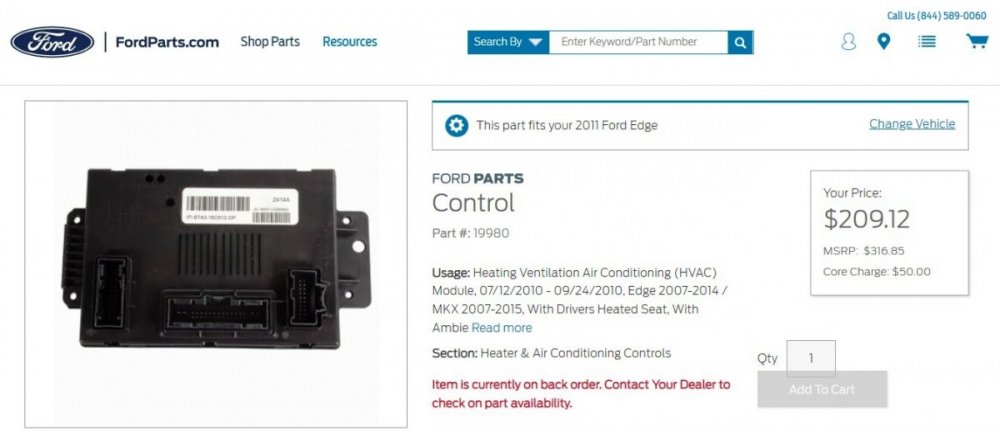

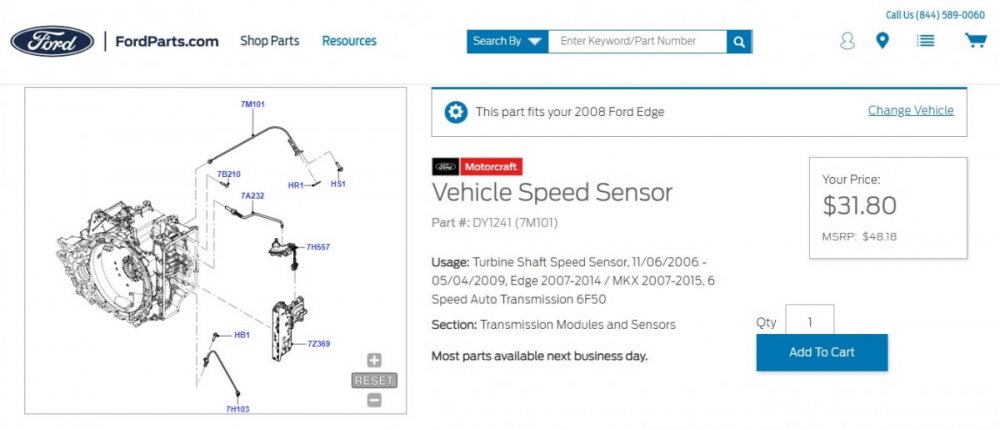

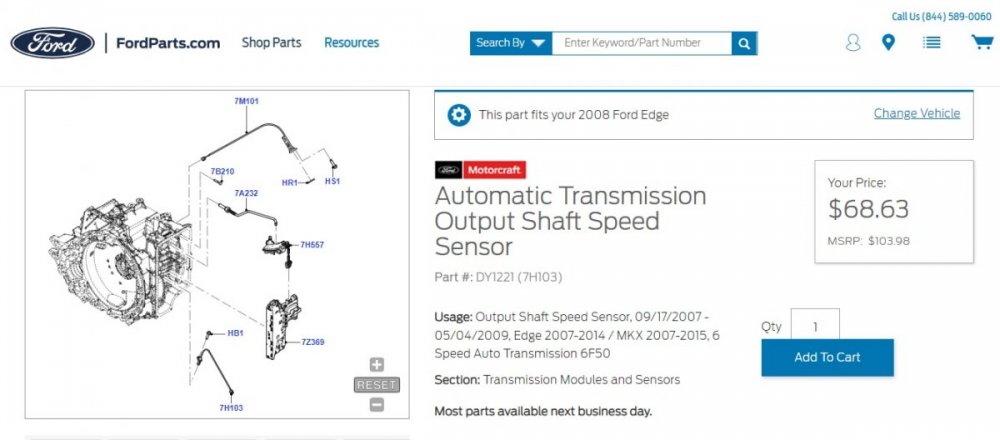

The following Climate Control System descriptions are from the 2011 Edge Workshop Manual... Dual-Zone Electronic Automatic Temperature Control (EATC) The dual-zone Electronic Automatic Temperature Control (EATC) module analyzes input from the following sources: Temperature, airflow mode, blower, A/C and RECIRC selection (made by the vehicle occupants) In-vehicle temperature sensor Ambient temperature sensor Solar radiation sensor (sunload sensor) Evaporator temperature sensor Vehicle speed Engine coolant temperature Using these inputs, the dual-zone HVAC module determines the correct conditions for the following outputs: A/C compressor operation Blower speed Temperature blend door position Airflow mode door position Air inlet door position Control System Inputs The dual-zone EATC system has 4 control system inputs. HVAC Module The EATC system uses a remote HVAC module that is separate from the control interface. The Front Controls Interface Module (FCIM) provides the interface for the vehicle occupants to control the climate control system. When selections are made, the FCIM communicates the selections to the HVAC module through the Medium Speed Controller Area Network (MS-CAN) , and the HVAC module adjusts the climate control system components to achieve the desired state. When the climate control system is operating in AUTO mode via command from the FCIM , the required climate control system settings are determined by the HVAC module. The HVAC module then adjusts the climate control system components to the desired state. The remote HVAC module is located under the driver side of the instrument panel. In-Vehicle Temperature Sensor The in-vehicle temperature sensor contains a thermistor which measures the in-vehicle air temperature and sends that reading to the HVAC module. An aspirator hose is connected between the heater core and evaporator core housing and the in-vehicle temperature sensor. The aspirator hose uses airflow through the heater core and evaporator core housing to create a venturi-type suction to draw in-vehicle air through the in-vehicle temperature sensor (across the thermistor). Solar Radiation Sensor (Sunload Sensor) The solar radiation sensor supplies information to the HVAC module indicating sunload. Ambient Temperature Sensor The ambient temperature sensor signal is received by the PCM and indicates the outside air temperature. The ambient temperature sensor is located in front of the radiator on the radiator support bolster. Control System Outputs The dual-zone EATC system has 4 control system outputs. Blower Motor Speed Control The blower motor speed control controls the blower motor speed by converting low power signals from the HVAC module to a high current, variable ground feed for the blower motor. A delay function provides a gradual increase or decrease in blower motor speed under all conditions. Temperature Blend Door Actuators The dual-zone EATC system uses 2 temperature blend door actuators to control 2 separate temperature blend doors. The temperature blend doors independently vary the LH and RH side temperature settings, as desired. The temperature blend door actuators each contain a reversible electric motor and a potentiometer. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the HVAC module from the contact wiper indicates the position of the temperature blend door. The HVAC module drives the actuator motor in whichever direction is necessary to make the actuator contact wiper voltage agree with the expected HVAC module contact wiper voltage value. Airflow Mode Door Actuator The airflow mode door actuator uses a cam and lever assembly to position the airflow mode doors on command from the HVAC module. The airflow mode door actuator contains a reversible electric motor and potentiometer. The potentiometer allows the HVAC module to monitor the position of the airflow mode doors. The potentiometer circuit consists of a 5-volt reference signal connected to one end of a variable resistor, and a signal ground connected to the other. A signal circuit is connected to a contact wiper, which is driven along the variable resistor by the actuator shaft. The signal to the HVAC module from the contact wiper indicates the position of the airflow mode doors. Air Inlet Mode Door Actuator The air inlet mode door actuator moves the air inlet door between the fresh and RECIRC positions on command from the HVAC module. The air inlet mode door actuator is driven to, and automatically stops at, the full RECIRC or full fresh air inlet position and does not require a potentiometer circuit to monitor its position. Climate Control System Network Communication The controls for the climate control system are in one or more locations depending on vehicle option content. Front Controls Interface Module (FCIM) Instrument Panel Cluster (IPC) (if equipped with steering wheel controls, Dual Automatic Temperature Control (DATC) only) Front Display Interface Module (FDIM) (if equipped with touchscreen controls, DATC only) For DATC systems equipped with touchscreen or steering wheel controls, when the FDIM touchscreen or IPC steering wheel controls are used, they send a function request message over the Infotainment Controller Area Network (I-CAN) to the FCIM . The FCIM reads the climate control selections and sends the requests to the HVAC module in the following message path: The FCIM sends the requests over the I-CAN to the IPC module. The IPC module then relays the requests to Body Control Module (BCM) over the High Speed Controller Area Network (HS-CAN) . Lastly, the BCM then sends the requests to the HVAC module over the Medium Speed Controller Area Network (MS-CAN) . For Electronic Manual Temperature Control (EMTC) systems, the messaging path is followed in reverse for any status updates that need to be sent from the HVAC module to the FCIM and Front Control/Display Interface Module (FCDIM) . For DATC systems, the messaging path is followed in reverse for any status updates that need to be sent from the HVAC module to the FCIM , FCDIM (non-touchscreen), FDIM (touchscreen) and IPC message center. Climate Control System Logic Blower Motor Speed When blower speed is selected, the FCIM sends the desired blower speed to the HVAC module using the message path described above. The HVAC module then commands the blower motor speed control to the desired speed. The HVAC module monitors the blower motor speed control feedback circuit to make sure the blower motor is at the desired speed. Airflow Mode Selection When an airflow mode is selected, the FCIM determines the applicable and allowable airflow direction. The FCIM then sends this desired airflow direction to the HVAC module using the message path described above. The HVAC module determines the actuator position that is required to deliver the correct airflow direction. While monitoring the defrost/panel/floor feedback circuit, the HVAC module drives the actuator until the feedback circuit indicates the actuator has reached its required position. Temperature Selection When a temperature is selected, the FCIM sends the desired temperature selection to the HVAC module using the message path described above. The HVAC module then determines the temperature blend door desired position. While monitoring the temperature blend door feedback circuit, the HVAC module drives the actuator until the feedback circuit indicates the actuator has reached its desired position. Air Inlet Selection When fresh air or RECIRC mode is selected, the FCIM sends the desired selection to the HVAC module using the message path described above. The HVAC module drives the air inlet mode door actuator until the HVAC module detects the actuator reached its end of travel. A spike in current draw tells the HVAC module the actuator has reached the end of its travel. A/C Selection When A/C is selected, the FCIM sends the selection to the HVAC module using the message path described above. If the ambient temperature is sufficient, the HVAC module then sends the request to the BCM over the MS-CAN . The BCM then sends the request to the PCM over the HS-CAN . Field-Effect Transistor (FET) Protection A Field-Effect Transistor (FET) is a type of transistor that, when used with module software, monitors and controls current flow on module outputs. The FET protection strategy prevents module damage in the event of excessive current flow. The HVAC module utilizes an FET protective circuit strategy for its actuator outputs. Output load (current level) is monitored for excessive current (typically short circuits) and is shut down (turns off the voltage or ground provided by the module) when a fault event is detected. A short circuit DTC is stored at the fault event and a cumulative counter is started. When the demand for the output is no longer present, the module resets the FET circuit protection to allow the circuit to function. The next time the driver requests a circuit to activate that has been shut down by a previous short (FET protection) and the circuit is still shorted, the FET protection shuts off the circuit again and the cumulative counter advances. When the excessive circuit load occurs often enough, the module shuts down the output until a repair procedure is carried out. The FET protected circuit has 3 predefined levels of short circuit tolerance based on the harmful effect of each circuit fault on the FET and the ability of the FET to withstand it. A module lifetime level of fault events is established based upon the durability of the FET . If the total tolerance level is determined to be 600 fault events, the 3 predefined levels would be 200, 400 and 600 fault events. When each tolerance level is reached, the short circuit DTC that was stored on the first failure cannot be cleared by a command to clear the DTCs. The module does not allow the DTC to be cleared or the circuit to be restored to normal operation until a successful self-test proves the fault has been repaired. After the self-test has successfully completed (no on-demand DTCs present), DTC U1000:00 and the associated DTC (the DTC related to the shorted circuit) automatically clears and the circuit function returns. When each level is reached, the DTC associated with the short circuit sets along with DTC U1000:00. These DTCs can be cleared using the module self-test, then the Clear DTC operation on the scan tool. The module never resets the fault event counter to zero and continues to advance the fault event counter as short circuit fault events occur. If the number of short circuit fault events reach the third level, then DTCs U1000:00 and U3000:49 set along with the associated short circuit DTC. DTC U3000:49 cannot be cleared and a new module must be installed after the repair. The following are HVAC Module DTCs, which are indicative of the vehicle functions the HVAC Module influences, also from the 2011 Edge Workshop Manual... HVAC Module DTC Chart NOTE: This module utilizes a 5-character DTC followed by a 2-character failure-type code. The failure-type code provides information about specific fault conditions such as opens or shorts to ground. Continuous Memory Diagnostic Trouble Codes (CMDTCs) have an additional 2-character DTC status code suffix to assist in determining DTC history. NOTE: Network DTCs (U-codes) are often a result of intermittent concerns such as damaged wiring or low battery voltage occurrences. Additionally, vehicle repair procedures such as module reprogramming often set network DTCs. Replacing a module to resolve a network DTC is unlikely to resolve the concern. To prevent repeat network DTC concerns, inspect all network wiring, especially connectors. Test the vehicle battery, refer to Section 414-01. DTC Description Action to Take B1034:11 Left Front Seat Heater Element: Circuit Short to Ground REFER to Section 501-10. B1034:13 Left Front Seat Heater Element: Circuit Open REFER to Section 501-10. B1036:11 Right Front Seat Heater Element: Circuit Short to Ground REFER to Section 501-10. B1036:13 Right Front Seat Heater Element: Circuit Open REFER to Section 501-10. B1038:11 Left Front Seat Heater Sensor: Circuit Short to Ground REFER to Section 501-10. B1038:12 Left Front Seat Heater Sensor: Circuit Short to Battery REFER to Section 501-10. B103A:11 Right Front Seat Heater Sensor: Circuit Short to Ground REFER to Section 501-10. B103A:12 Right Front Seat Heater Sensor: Circuit Short to Battery REFER to Section 501-10. B1081:07 Left Temperature Damper Motor: Mechanical Failure GO to Pinpoint Test O. B1081:11 Left Temperature Damper Motor: Circuit Short to Ground GO to Pinpoint Test O. B1081:12 Left Temperature Damper Motor: Circuit Short to Battery GO to Pinpoint Test O. B1081:13 Left Temperature Damper Motor: Circuit Open GO to Pinpoint Test O. B1082:07 Right Temperature Damper Motor: Mechanical Failure GO to Pinpoint Test P. B1082:11 Right Temperature Damper Motor: Circuit Short to Ground GO to Pinpoint Test P. B1082:12 Right Temperature Damper Motor: Circuit Short to Battery GO to Pinpoint Test P. B1082:13 Right Temperature Damper Motor: Circuit open GO to Pinpoint Test P. B1086:07 Air Distribution Damper Motor: Mechanical Failure GO to Pinpoint Test J. B1086:11 Air Distribution Damper Motor: Circuit Short to Ground GO to Pinpoint Test J. B1086:12 Air Distribution Damper Motor: Circuit Short to Battery GO to Pinpoint Test J. B1086:13 Air Distribution Damper Motor: Circuit Open GO to Pinpoint Test J. B10AF:12 Blower Fan Relay: Circuit Short to Battery GO to Pinpoint Test Q. B10AF:13 Blower Fan Relay: Circuit Open GO to Pinpoint Test Q. B10B9:12 Blower Control: Circuit Short to Battery GO to Pinpoint Test R. B10B9:14 Blower Control: Circuit Short to Ground or Open GO to Pinpoint Test Q. B11E5:11 Left HVAC Damper Position Sensor: Circuit Short to Ground GO to Pinpoint Test O. B11E5:15 Left HVAC Damper Position Sensor: Circuit Short to Battery or Open GO to Pinpoint Test O. B11E6:11 Right HVAC Damper Position Sensor: Circuit Short to Ground GO to Pinpoint Test P. B11E6:15 Right HVAC Damper Position Sensor: Circuit Short to Battery or Open GO to Pinpoint Test P. B11E7:11 Air Distribution Damper Position Sensor: Circuit Short to Ground GO to Pinpoint Test J. B11E7:15 Air Distribution Damper Position Sensor: Circuit Short to Battery or Open GO to Pinpoint Test J. B127B:11 Ambient Lighting Zone 1 Output Red LED: Circuit Short to Ground REFER to Section 417-02. B127B:13 Ambient Lighting Zone 1 Output Red LED: Circuit Open REFER to Section 417-02. B127C:11 Ambient Lighting Zone 2 Output Red LED: Circuit Short to Ground REFER to Section 417-02. B127C:13 Ambient Lighting Zone 2 Output Red LED: Circuit Open REFER to Section 417-02. B127D:11 Ambient Lighting Zone 3 Output Red LED: Circuit Short to Ground REFER to Section 417-02. B127D:13 Ambient Lighting Zone 3 Output Red LED: Circuit Open REFER to Section 417-02. B127E:11 Ambient Lighting Zone 1 Output Green LED: Circuit Short to Ground REFER to Section 417-02. B127E:13 Ambient Lighting Zone 1 Output Green LED: Circuit Open REFER to Section 417-02. B127F:11 Ambient Lighting Zone 2 Output Green LED: Circuit Short to Ground REFER to Section 417-02. B127F:13 Ambient Lighting Zone 2 Output Green LED: Circuit Open REFER to Section 417-02. B1280:11 Ambient Lighting Zone 3 Output Green LED: Circuit Short to Ground REFER to Section 417-02. B1280:13 Ambient Lighting Zone 3 Output Green LED: Circuit Open REFER to Section 417-02. B1281:11 Ambient Lighting Zone 1 Output Blue LED: Circuit Short to Ground REFER to Section 417-02. B1281:13 Ambient Lighting Zone 1 Output Blue LED: Circuit Open REFER to Section 417-02. B1282:11 Ambient Lighting Zone 2 Output Blue LED: Circuit Short to Ground REFER to Section 417-02. B1282:12 Ambient Lighting Zone 2 Output Blue LED: Circuit Short to Battery REFER to Section 417-02. B1283:11 Ambient Lighting Zone 3 Output Blue LED: Circuit Short to Ground REFER to Section 417-02. B1283:13 Ambient Lighting Zone 3 Output Blue LED: Circuit Open REFER to Section 417-02. B12F1:11 Ambient Lighting Zone 1 Output : Circuit Short to Ground REFER to Section 417-02. B12F1:13 Ambient Lighting Zone 1 Output : Circuit Open REFER to Section 417-02. B12F2:11 Ambient Lighting Zone 2 Output : Circuit Short to Ground REFER to Section 417-02. B12F2:13 Ambient Lighting Zone 2 Output : Circuit Open REFER to Section 417-02. B1321:11 Ambient Lighting Zone 3 Output: Circuit Short to Ground REFER to Section 417-02. B1321:13 Ambient Lighting Zone 3 Output: Circuit Open REFER to Section 417-02. B1A61:11 Cabin Temperature Sensor: Circuit Short to Ground GO to Pinpoint Test D. B1A61:15 Cabin Temperature Sensor: Circuit Short to Battery or Open If only DTC B1A61:15 is set, GO to Pinpoint Test D. If DTC B1A61:15, B1A63:15 and B1A64:15 all set, GO to Pinpoint Test T. B1A63:11 Right Solar Sensor: Circuit Short to Ground GO to Pinpoint Test E. B1A63:15 Right Solar Sensor: Circuit Short to Battery or Open If only DTC B1A63:15 is set, GO to Pinpoint Test E. If DTC B1A61:15, B1A63:15 and B1A64:15 all set, GO to Pinpoint Test T. B1A64:11 Left Solar Sensor: Circuit Short to Ground GO to Pinpoint Test E. B1A64:15 Left Solar Sensor: Circuit Short to Battery or Open If only DTC B1A64:15 is set, GO to Pinpoint Test E. If DTC B1A61:15, B1A63:15 and B1A64:15 all set, GO to Pinpoint Test T. B1B71:11 Evaporator Temperature Sensor: Circuit Short to Ground GO to Pinpoint Test F. B1B71:15 Evaporator Temperature Sensor: Circuit Short to Battery or Open GO to Pinpoint Test F. B1C83:11 Rear Defog Relay: Circuit Short to Ground REFER to Section 501-11. B1C83:13 Rear Defog Relay: Circuit Open REFER to Section 501-11. C1B14:11 Sensor Supply Voltage A: Circuit Short to Ground GO to Pinpoint Test C. C1B14:12 Sensor Supply Voltage A: Circuit Short to Battery GO to Pinpoint Test C. U0140:00 Lost Communication With Body Control Module: No Sub Type Information GO to Pinpoint Test S. U0401:09 Invalid Data Received From ECM/PCM A: Component Failure This DTC can set due to a fault in the PCM. CARRY OUT a self-test of the PCM and DIAGNOSE any PCM DTCs present, REFER to Section 303-14. U0401:68 Invalid Data Received From ECM/PCM A: Event Information This DTC can set due to a fault in the PCM. CARRY OUT a self-test of the PCM and DIAGNOSE any PCM DTCs present, REFER to Section 303-14. U0401:81 Invalid Data Received From ECM/PCM A: Invalid Serial Data Received This DTC can set due to a fault in the PCM. CARRY OUT a self-test of the PCM and DIAGNOSE any PCM DTCs present, REFER to Section 303-14. U0401:82 Invalid Data Received From ECM/PCM A: Alive/Sequence Counter Incorrect/Not Updates This DTC can set due to a fault in the PCM. CARRY OUT a self-test of the PCM and DIAGNOSE any PCM DTCs present, REFER to Section 303-14. U0422:68 Invalid Data Received From Body Control Module: Event Information This DTC can set due to a fault in the Body Control Module (BCM) . CARRY OUT a self-test of the BCM and DIAGNOSE any BCM DTCs present, REFER to Section 419-10. U0422:81 Invalid Data Received From Body Control Module: Invalid Serial Data Received This DTC can set due to a fault in the Body Control Module (BCM) . CARRY OUT a self-test of the BCM and DIAGNOSE any BCM DTCs present, REFER to Section 419-10. U0423:82 Invalid Data Received From Instrument Panel Cluster Control Module: Alive/Sequence Counter Incorrect/Not Updates This DTC can set due to a fault in the Instrument Panel Cluster (IPC) . CARRY OUT a self-test of the IPC and DIAGNOSE any IPC DTCs present, REFER to Section 413-01. U0554:82 Invalid Data Received From Accessory Protocol Interface Module: Alive/Sequence Counter Incorrect/Not Updates This DTC can set due to a fault in the Accessory Protocol Interface Module (APIM) . CARRY OUT a self-test of the APIM and DIAGNOSE any APIM DTCs present, REFER to Section 415-00. U1000:00 Solid State Driver Protection Activated — Driver Disabled: No Sub Type Information The HVAC module has temporarily disabled an output because an excessive current draw exists (such as a short to ground). The HVAC module cannot enable the output until the cause of the short is corrected. ADDRESS all other DTCs first. After the cause of the concern is corrected, CLEAR the DTCs. REPEAT the self-test. U2024:51 Control Module Cal-Config Data: Not Programmed CARRY OUT Programmable Module Installation (PMI) on the HVAC module. REFER to Section 418-01. REPEAT the self-test. If PMI is successful, the DTC will not be present. If the DTC returns, INSTALL a new HVAC module. REFER to Section 412-01. TEST the system for normal operation. U2100:00 Initial Configuration Not Complete: No Sub Type Information CARRY OUT Programmable Module Installation (PMI) on the HVAC module. REFER to Section 418-01. REPEAT the self-test. If PMI is successful, the DTC will not be present. If the DTC returns, INSTALL a new HVAC module. REFER to Section 412-01. TEST the system for normal operation. U3000:41 Control Module: General Checksum Failure INSTALL a new HVAC module. REFER to Section 412-01. TEST the system for normal operation. U3000:49 Control Module: Internal Electronic Failure The module has permanently disabled an output because an excessive current draw fault (such as a short to ground) has exceeded the limits that the HVAC module can withstand. The cause of the excessive current draw MUST be corrected before a new HVAC module is installed. ADDRESS all other DTCs first. After the cause of the concern is corrected, INSTALL a new HVAC module. REFER to Section 412-01. TEST the system for normal operation. U3002:62 Vehicle Identification Number: Signal Compare Failure CARRY OUT Programmable Module Installation (PMI) on the HVAC module. REFER to Section 418-01. REPEAT the self-test. If PMI is successful, the DTC will not be present. If the DTC returns, INSTALL a new HVAC module. REFER to Section 412-01. TEST the system for normal operation. U3003:16 Battery Voltage: Circuit Voltage Below Threshold GO to Pinpoint Test G. U3003:17 Battery Voltage: Circuit Voltage Above Threshold GO to Pinpoint Test G. So. while various DTCs refer to specific Pinpoint diagnostic routines, the symptom of Blower Motor Does Not Operate Correctly indicates Pinpoint Test R, for which PDF download links of the diagnostic procedure and associated Workshop Manual selections are included below, along with images of wiring diagrams, connector location diagrams, and a FordParts online listing for the HVAC Module part # 19980. Good luck! Pinpoint Test R - The Blower Motor Does Not Operate Correctly - 2011 Edge Workshop Manual.pdf HVAC Module Connector C228A Wiring-Circuit Legend - 2011 Edge Workshop Manual.pdf Blower Motor Speed Control Connector C271 Wiring-Circuit Legend - 2011 Edge Workshop Manual.pdf Instrument Panel Exploded View - 2011 Edge Workshop Manual.pdf Blower Motor Speed Control Removal and Installation - 2011 Edge Workshop Manual.pdf HVAC Module Removal and Installation - 2011 Edge Workshop Manual.pdf Module Configuration Parameters Includes HVAC Module - 2011 Edge Workshop Manual.pdf

ConnectorC2280CLocationDiagram-2014EdgeWorkshopManual.jpg.c7abdca96ae92be7fae90fed392f6c45.jpg)