-

Posts

436 -

Joined

-

Last visited

-

Days Won

35

Content Type

Profiles

Forums

Gallery

Everything posted by Cerberus

-

this thread is over 3 years old.. unless i'm missing something?

-

I dont know for your vehicle off hand, I'd have to figure it out from looking. It will be the skinnier of the two, and will flow to the condenser

-

Ford Pass: vehicle in battery saver mode

Cerberus replied to sc00by's topic in Alarms, Keyless Entry, Locks & Remote Start

gotta love a happy ending. but just to be sure, it might be worth checking your charging voltage at idle, and if you have Forscan you can even read the alternator output current from the alternator current output sensor. I was getting the battery saver mode warning on mine before my alternator failed. -

if you end up seeing some extreme pressures with standard or low refrigerant charge level, you may have a ruptured desiccant pack in the receiver / dryer.. Might be a long shot, but its possible, and it would explain leakage out the blow off. If its not leaking from the blow off, its most likely leaking from the high side line seal at the compressor. That would actually be good news. Point of interest, the vacuum test, while useful, can be misleading because sometimes seals really only seal well in one direction (pressure) I've had systems not hold vacuum well, but hold their charge just fine. The opposite can also be true.

-

Are FRAM ULTIMATE oil filters safe to use?

Cerberus replied to 1004ron's topic in Accessories & Modifications

filters are a subject of particular interest (hah!) to me everything is a compromise. You have several conflicting parameters to work within, like oil pressure & flow rate, versus engine drag which effects fuel economy. But of course, the required oil flow at a specific viscosity is a non-negotiable value for any given engine, defined by machining tolerances and wear. Pressure requirements are contingent on clearances and load (power stroke) on the bearing to journal mating. Flow requirements are contingent on how quickly the pressurized journals squirt their cushion out, and back to the pan (which again is influenced by design clearances & wear) You can make a filter that would not let anything over 0.1 micron particulate through it, BUT, you'd never get enough flow to make the pressure to float your bearings unless it had Massive surface area. The Mann filter does look like it has a lot more surface area but being a cellulose filter media, the pose sizing is highly irregular compared to a woven synthetic filter media, and that irregularity makes for some larger pores (bad for filtration but great for flow) and some tight pores which are arguably wasted filter surface until or unless the large pores are filled up. But is won't crush because it is flowing a lot of (less clean) oil. The primary benefit of synthetic filter media is that a tightly woven synthetic media can have extremely predictable and normalized small pore size which allows for a high level of filtration without being too restrictive to flow rate. But a heavy oil at high flow rates will still exert a lot of pressure on the media and crush it if it is not well supported. -

Are FRAM ULTIMATE oil filters safe to use?

Cerberus replied to 1004ron's topic in Accessories & Modifications

seems like there should a cage inside to support the media. most cartridge filters have some kind of a cage inside to protect the filter from being crushed by the pressure differential I will say that the synthetic media Fram filters for mine (2.7) do have the cage inside to support the media and do not have any crush problem. -

if i am understanding you correctly, you changed the fluid of the first two units at around 30k and then ran them to 90k before they blew up? so you got 60K out of them.. which is longer than I would run them without a fluid change personally, particularly if they are the version that only hold 0.35 quart... Change the fluid every 30k at least and the 3rd vehicle's PTU will last longer.. unless its just a generation of PTU with a poor build design. but i do agree, i was not amused by Ford with the captive water pump design on the early 3.5.. that was an expensive lesson. And the salesman I was going to buy a warranty from was not amused by his king ranch needing cam phasers and the price that his own service department gave him.. And i'm definitely not amused by the idea of wet belt driving an oil pump..

-

Agreed. Unless there was an auxiliary oil pump to maintain lubrication, auxiliary water pump to maintain significant coolant flow and a non-wearing (magnetic?) drive for the starter interface, I have not, do not and will not trust auto start / stop systems. And of course, none of those things would even address the starter / alternator / battery workload issue. The auto start/stop fleet vehicles I work on (Mercedes not Ford) are burning out starters (solenoids mostly) alternators (pulley clutches mostly) and batteries, in 3 years of service and under 40k miles

-

I dont think 5k is a reasonable price for the water pump job.. but I might be wrong.. I'd have guess 2-3k tops. If you have options, shop the job, but never do business with the cheapest place either, unless they come well recommend from other customers

-

I'd be using an ultraviolet lamp and glasses to track the leak down. no point in replacing what might be fine, at least not until you know what is the actual problem. obviously leaking, possible blow off valve dumping prematurely, but to e honest, i've never heard of that happening. probably a pin hole in the condenser, leaking shrader valve or seal failure at the compressor high side line

-

I tend to believe there is no such thing as a coincidence. now, a 2010 3.5, that has the water pump inside the timing cover, yes? My 2011 fusion sport had the same engine and a captive water pump, so I'm presuming yours is the same. That does make it a major PITA. If you look down the front of the block behind the alternator, you may see a discolored stripe where its been leaking from the weep hole which is designed to route leaking coolant out of the engine. If it has been leaking for some time, and the leak is close to the charging cable, that could explain the corrosion.. so IF the situation is as I suspect, It's likely that the pump was failed before the alternator problem presented itself in an obvious way. as long as your engine oil is not milked up, its probably worth fixing, but it will likely be expensive, because as I said, it is a major PITA if your engine is not the one with the captive water pump, disregard all.

-

Replaced brake pads and rear rotors and worse than before

Cerberus replied to ewaters's topic in Brakes, Chassis & Suspension

It is possible that the screeching is actually not the sensors squealing, but a very hard metallic or ceramic compound pad with poor installation (original rotors, no lube) The fleet I work on (not Ford) transitioned from OEM pads that burned up in under 10K miles, but were silent, to a ceramic pad that will last a lot longer, but if the backs of the pads are not greased, they definitely like to squeal. There have been A LOT of visits for on site brake changes that are unnecessary.. see if you can actually see the pad thickness ? -

RDU Motor Actuator, failure advice? Part number?

Cerberus replied to Gnerffed's topic in Brakes, Chassis & Suspension

You answered your own question.. Not trying to ruffle anyone's feathers but the pattern is kind of obvious at some point. Same reason GM canceled the 3800. It lasted too long.- 13 replies

-

- 1

-

-

- speed and position sensor

- rdu actuator motor

-

(and 2 more)

Tagged with:

-

What have you done to/with your Edge/MKX today?

Cerberus replied to WWWPerfA_ZN0W's topic in Accessories & Modifications

i went with this one. Definite upgrade from OEM and for a few bucks cheaper https://www.amazon.com/dp/B07664V1JN -

What have you done to/with your Edge/MKX today?

Cerberus replied to WWWPerfA_ZN0W's topic in Accessories & Modifications

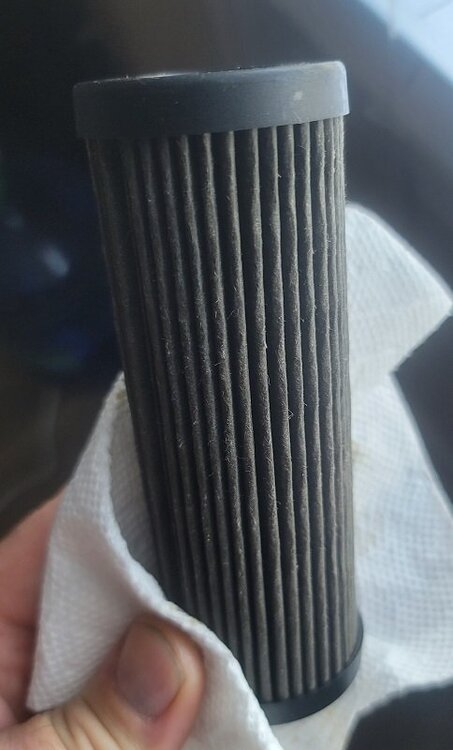

Oil change Wanted to do the air filters but I received the wrong engine air filter and the cabin air filter was dimensionally abnormal, would not fit in the slot. Don't ignore your cabin air filters.. mine is nasty. New one arriving from Amazon today hopefully. -

Really Need Help with Weird Suspension Issue

Cerberus replied to atdi2113's topic in Brakes, Chassis & Suspension

bent wheel? warped rotor? bad tie rod end? IDK camber being off will not create a shake a brand new part failing is not common, but not impossible either.. personally i'd go over every single bolt and part that has been touched since the struts were done -

here's an option from an older thread

-

RDU Motor Actuator, failure advice? Part number?

Cerberus replied to Gnerffed's topic in Brakes, Chassis & Suspension

i gave it a quick wide search and i'm coming up with a lot of dead ends. I can find the RDU and the viscous coupler (which i suspect is not even for your application) but no component level availability.- 13 replies

-

- speed and position sensor

- rdu actuator motor

-

(and 2 more)

Tagged with:

-

I'd bet you a beer that the pulley on the alternator is slipping. not the belt, the pulley itself. You can't adjust the belt tension, is spring loaded. But i just had pretty much the same problem and i replaced the alternator, but realized afterwards that the pulley (clutched overrun disconnect type) was free wheeling in both directions. We've seen a few of these on the vehicles i work on in the shop too. Different make and model, but still, these clutching pulleys are suspect as hell. oh, and my battery warning light did not come on with mine either until it was pretty much cooked.

- 5 replies

-

- 1

-

-

- warning light

- battery

-

(and 1 more)

Tagged with:

-

Long Story and Dealer Shaming

Cerberus replied to Cerberus's topic in Dealership & Vendor Experiences

the age and mileage of your vehicle has a large impact on pricing of the plan I'm talking with a ford dealer to arrange a 2yr/24,000 mile powertrain warranty for about 1600. But mine is a 2016 with about 105K miles -

the turbo vehicles i work on have started presenting with this problem, and so far its been the vacuum diaphragm that actuates the wastegate control that fails. no longer holds vacuum, so it does not pull the flap shut to force all flow through the turbine. different brand & model but worth a look as a first thing to eliminate

-

This is the most common reason to replace tensioner or idler, bearing noise or crunching

-

In my case the tensioner had to come off to get the alternator off, so as long as it is off anyway, why put an old one back on? The spring could have gotten weak and lost tension, the bearing could be getting tired. This does happen. Think about the diameter of the tensioner and idler relative to the crank pulley, and how many times x how fast those things spin.. As it turns out, I definitely didn't need to replace it. Truth is even the belt was showing no signs of wear (at over 100k) but screw it, cheap insurance and I already had the parts in hand.

-

rock auto for the win when i did my alternator a month ago, I replaced the belt and tensioner but not the idler, and it was tight as hell. I like Gates, but went with a motocraft tensioner I had to ratchet strap the ratchet handle to the subframe in the fully retracted position, and put a socket on the crank to rotate it slowly to roll the belt on. I'm no noob, it was that tight.

-

Tone sound when accelerating from a stop

Cerberus replied to Dena's topic in Alarms, Keyless Entry, Locks & Remote Start

have the alternator tested immediately. The battery may be low also, but likely as a symptom of the alternator, if it is bad. I had the same message on my sync display about systems being shut off to save the battery, immediately after shutting off the vehicle instead of the radio staying on until the door is opened (or a few minutes) Turns out, my alternator pulley was freewheeling, not charging.