Leaderboard

Popular Content

Showing content with the highest reputation since 02/13/2025 in all areas

-

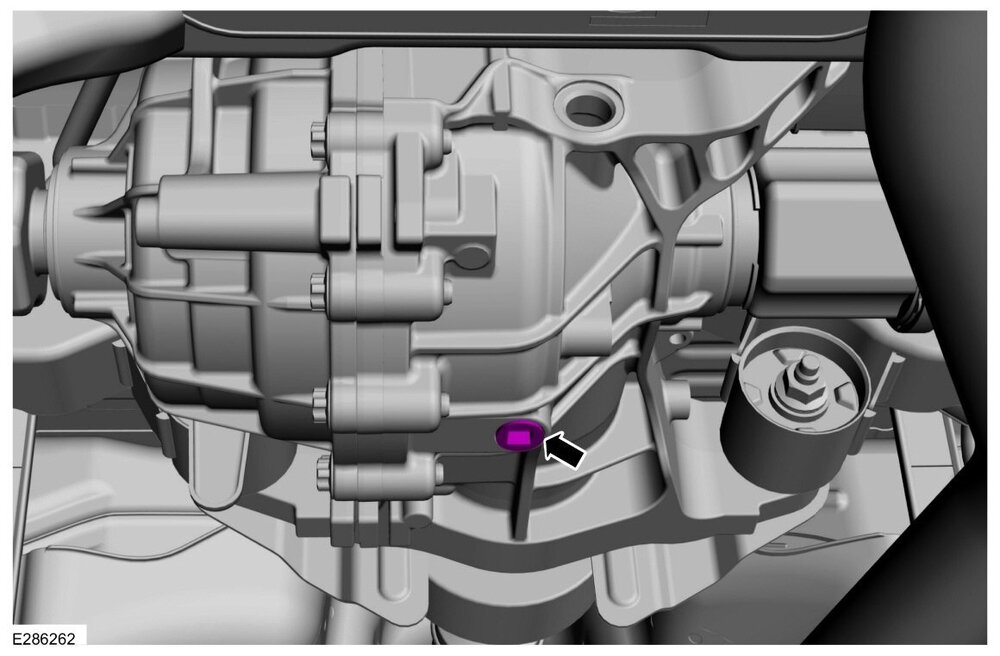

Not lot of detailed info on this; only a handful of threads here. The procedure was pretty simple but has gotchas and other things I didn't really care for. For example the torque on the PTU fill plug, you'll never get 33 ft/lbs on that. I stopped turning before I got to 28 ft/lb and noticed the plug was deeper than when I first took it out and stopped. There's also no way, as mentioned in another thread here, that you can completely remove the PTU cooler without removing the crossmember there. You can however, pull the cooler out far enough to drain the fluid. Make sure not to screw up the o-ring on the cooler though, or you will be dropping the crossmember. Those of you with just a plug here and no cooler don't have to worry about this as your plug comes right out. Here's the fill plug and PTU cooler with the stud/nut showing. When I opened the fill plug not even a dribble of fluid came out. I had to use a combo of 1/4" 8mm socket and 8mm flex head closed end ratchet on the nuts. Or you can drop the exhaust. I kept the 1-piece stud/nut and just reused them. The PTU cooler pops out easily, or as much as it can before hitting the subframe. The coolers metal rod elements extend the length of PTU basically. Here she is draining. You can see the o-ring - do not mess it up. Brake cleaner will be your exhausts best friend. I'd say I spilled an ounce or more other than what's in the container but I tried to measure what came out of it. In the sun. Didn't look too bad I thought for ~35k miles but idk. Reinstalled PTU cooler and cleaned everything up. Inserted the stud/nuts and torqued to 97 in/lb Here's what I use to fill up transmissions and differentials. Just a regular water vacuum pump you can get on Amazon for $10. Easy peasy no mess no pumping just press a button. I put as much oil as it would take until it started streaming out. Then I spun the tires several times by hand and waited a few more minutes before pumping more fluid in. When the stream stopped and turned into a drip I put the fill plug back on with some thread sealant. Like I said above I don't like how Ford says 33 ft/lbs on the fill plug - that's not happening at least on mine. All cleaned up and done. I'll check the level again in 100 miles or so. The fill plug is inserted further than it was from the factory at 28ft/lbs. Be careful with aluminum. And that's pretty much it. It should take about an hour if you have access to a lift. As with everyone else, I have no idea why Ford couldn't put a drain plug other than to purposely let PTU's eat themselves after the warranty period.8 points

-

7 points

-

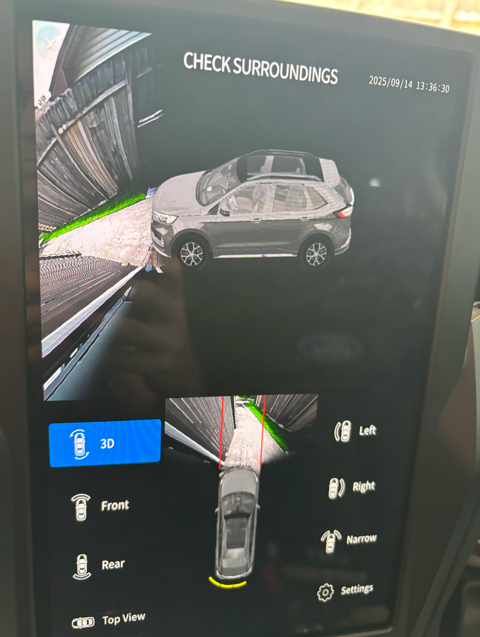

Hello everyone, I’ve been following this thread with a lot of interest — great work from all of you digging into the 360 retrofit! I’ve been wanting to achieve a similar result, but I decided to take a different approach. I went with a third-party 360 AVM kit and set it up to integrate with the SYNC screen on my 2023 Ford Edge. There really isn’t anything compatible out of the box with the Edge, but I noticed the Edge and Ranger share similar hardware and modules. And notice I said similar — not the same. It’s been a long process — I’ve done tons of research and a fair amount of trial and error to figure out the video inputs, CANBUS integration, and DIP switch configurations needed to get everything displaying correctly with the factory screen and triggers. With this I do have dynamic guidelines, parking sensors, multiple views along with the top-down bird view. Also I did retain the factory camera and camera view, and I can jump between factory view and 360 kit view. It’s still a work in progress, but going this route gives me more flexibility compared to being locked into the OEM restrictions. I’ll share more updates as I continue refining the setup. Next steps will be to mount all the cameras7 points

-

I wasn't happy with the light in the trunk at all. If the light isn't blocked, then everything is fine. But when it's blocked, it's hard to find anything. The lampshade is inserted into a frame made of textolite. I disassembled the right side of the interior to lower the ceiling. We connect to the rear right light. We place the lantern in the middle, carefully cut it out and insert it. We get the final result.5 points

-

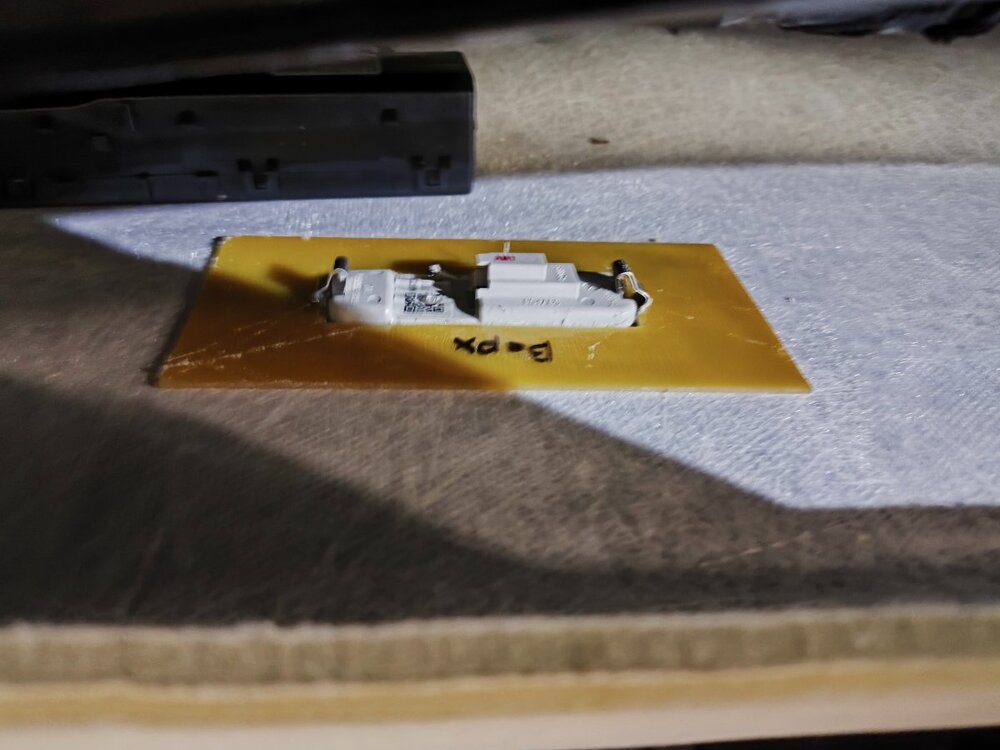

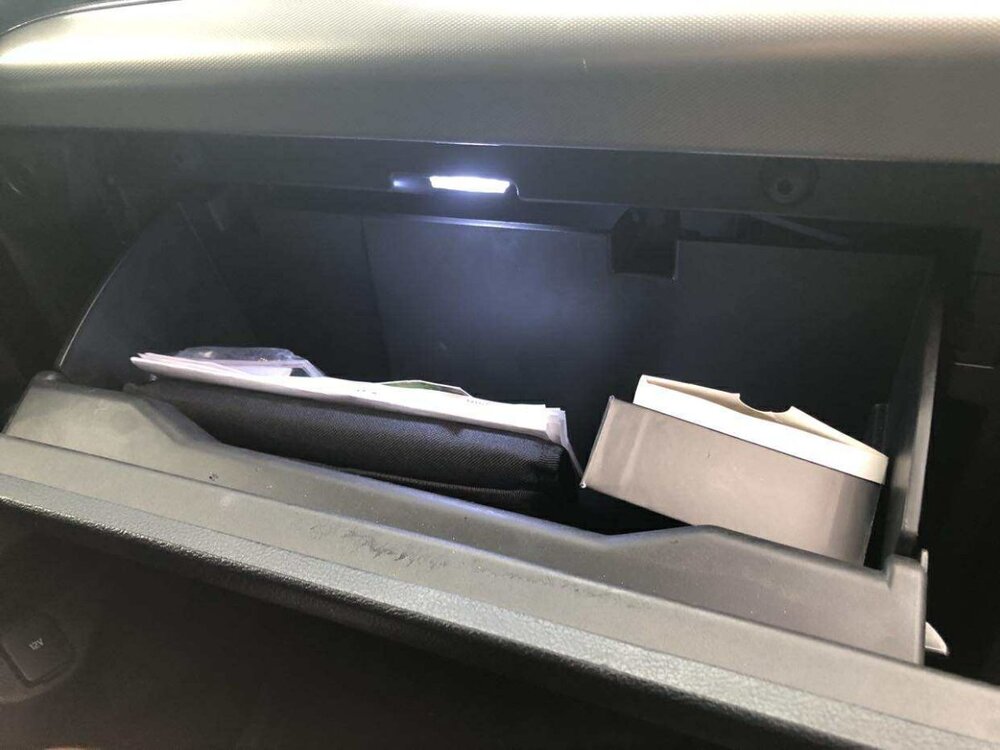

The little things matter 😉 Added glove box compartment light back in the Edge. Don't know why Ford deleted it in the first place. Scored a 2017 Edge glove box lamp harness and damper from the junkyard. With a little bit of DIY (dremel action & soldering), swapped out the LED PCB for a brighter aftermarket one. I made a T-harness to tap into the passenger side (visor) vanity mirror lamp circuit. Ran that down the psngr side A-pillar all the way to the glove box.5 points

-

5 points

-

alright, so its lane changing, never had awd so i kept looking at awd symptoms and solutions, i found it turned it off will drive tomorrow to see what happens technology is killing/saving me if you ever need help with a 73-79 f100 let me know, simplicity is awesome thanks for the help could not have done it without your insight5 points

-

5 points

-

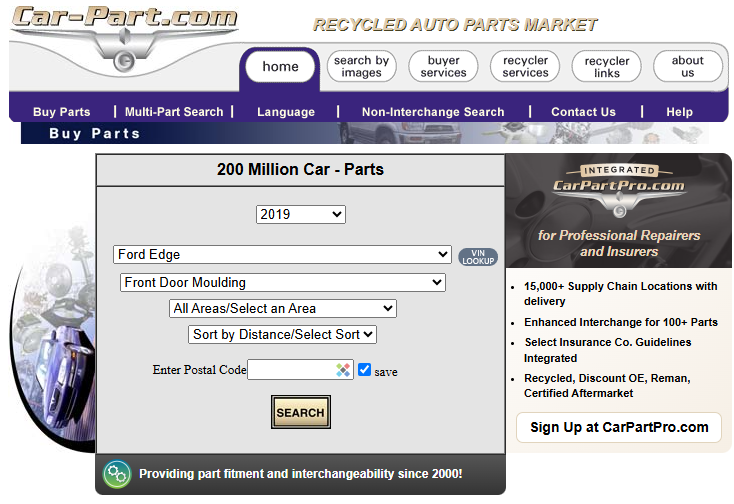

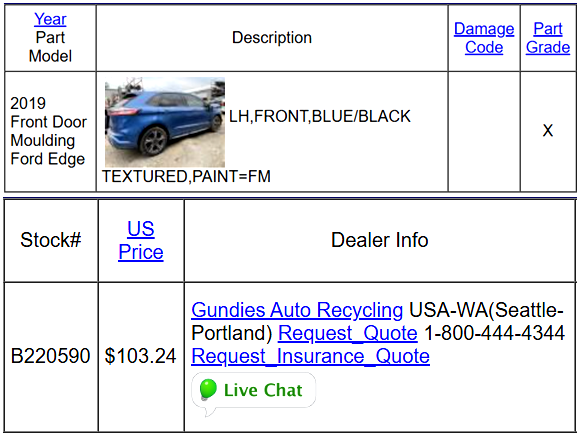

Welcome to the Forum @Kellmac! The 2020 Edge Workshop Manual indicates the Rear Door Moulding panel is retained to the body by eleven (11) clips attached to the panel's molded-in pedestals. You might try putting a square of masking tape or low-tack painter's tape on the outer face of the panel corresponding to each of the eleven pedestals, to ensure that you are directly engaging each and every retaining clip. If any of your Edge's clips appear to be damaged when compared to the below photo, replacement clips are available per Ford's online parts-selling site, and through your local dealer's Parts Department. And finally, the 2020 Edge Workshop Manual removal & installation procedure is attached below as a PDF document. Good luck! Link to this FordParts webpage Rear Door Moulding - Removal and Installation - 2020 Edge Workshop Manual.pdf5 points

-

That press release looks to me like they planned to relabel they BG44K in the Ford branded package. I can vouch for the 44K stuff in the 2.7. Having used it, the stuff is legit.4 points

-

I finally wrapped up the full camera system install on my Edge. Front Camera I swapped out the factory grille for a black one that already had the camera mount integrated. Definitely the cleanest way to do it — no drilling and a perfect OEM-style fit. Side Cameras The side mirrors were straightforward. Routing the wiring and lining up the cameras was easy. Just a bunch of plastics to remove. Rear Camera This one took the most work. Like I mentioned in my previous post I wanted to retain the factory camera and system, and just add the new camera for the 360 view. I had to get creative. I decided to embed the camera in the logo. Marked and dremel’d out a custom recess behind the Ford emblem. Mounted the camera flush and secured it internally. Ran the wiring through the hatch. Calibrated the image afterward so the lines lined up correctly Honestly, this was the toughest part, but I’m happy with how the end result looks. I think I could have done a better job, or maybe could have thought of something else. But also I really wanted to finish the project. I think I'm going to redo the calibration after the holidays to get a better results but overall it's good. If anyone has ideas for cleaner mounting, I’m all ears.4 points

-

Wanting to spend a few hundred dollars wisely? Drive through the poor section of your town and drop 30 $10 dollar bills out the window or, pick an Angel off the Christmas Tree @ the mall. Watch the video before you spend your hard earned $$$$!4 points

-

4 points

-

I wanted to provide some closure on my whine/roar. After spraying the center bushing with lubricant and the whine/roar going away, I pulled the trigger and ordered a new center bushing. I used ramps on the passenger side to have the length of the vehicle up. I had to drop the exhaust, prior to cat (had to grind off the bolts), I then jacked up the front driver side to get the wheel enough off the ground so I could turn the driveshaft. I did put the transmission in Neutral, with the parking brake on and the rear driver wheel chalked. I removed the bolts holding the shaft on. The ends were "stuck". I sprayed with penetration fluid. I used some force, and mistakenly pulled the dust housing off the rear (very bad move on my part). I finally had to use a chisel and tap it out. The front came out with no issues. No matter the videos I watched. the amount of force I applied or the penetration fluid I applied, the shaft was NOT separating. After looking more at the rear of the shaft, I realized that by pulling off the dust cover, it was going to be an issue if I was able to get it back together. I had to order a new driveshaft. In the meantime, we drove the car for 2 weeks without a drive shaft with zero issues. No check engine lights nor performance issues that I could tell. I installed the new driveshaft, with the new center bushing and it's back to normal. No whine at all. At the end of the day, l spent a lot of time on my back and learned some lessons, but I think I still made out spending less than going to the dealer. I hope this helps someone.4 points

-

While the tips are in shadows, they look to be burning correctly, the tips worn round, and the end of the ground strap eroded, so certainly time to get it done. I did mine earlier just to get it done during a good time to work, between long drives, weather cooperating, etc. I did mine at 82k, a little erosion on the ground strap, but the precious metal tip was still square, could have gone much much longer, but for how cheap it was to do, if I pull them I replace them.4 points

-

Also, as far as I know, the oil life monitor also takes into account time with the maximum time being 12 months. So if you change the oil as suggested above at 50%, you would be more certainly changing the oil at no more than 5,000 mile or 6 months from when it was last reset. Or you can interpolate the interval you want, knowing that 100% means 10k miles or 12 months. For example, 60% oil life balance would mean 4k miles or 4.8 months.4 points

-

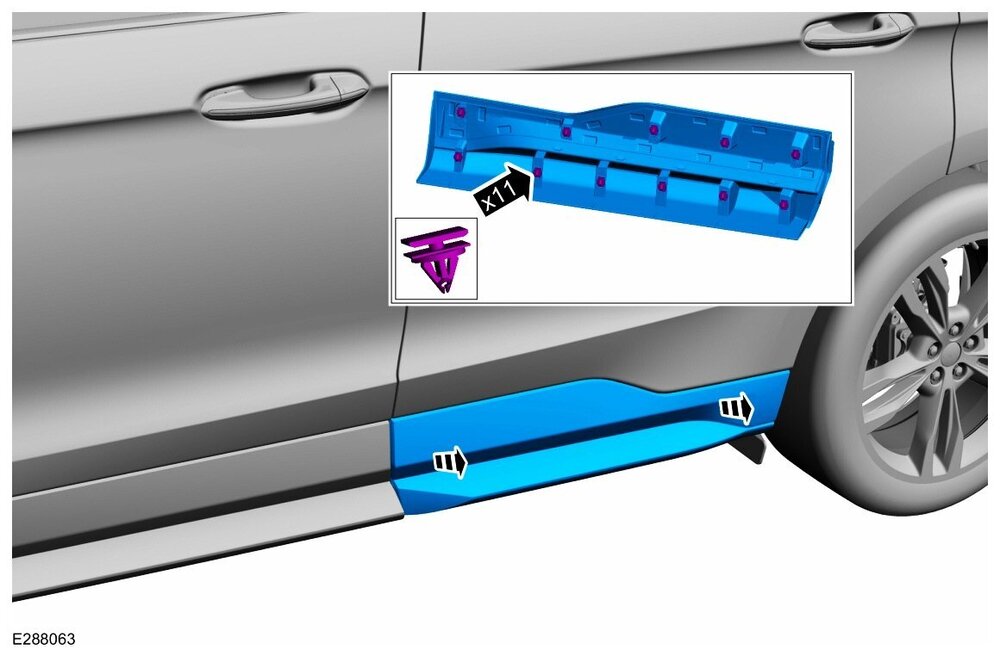

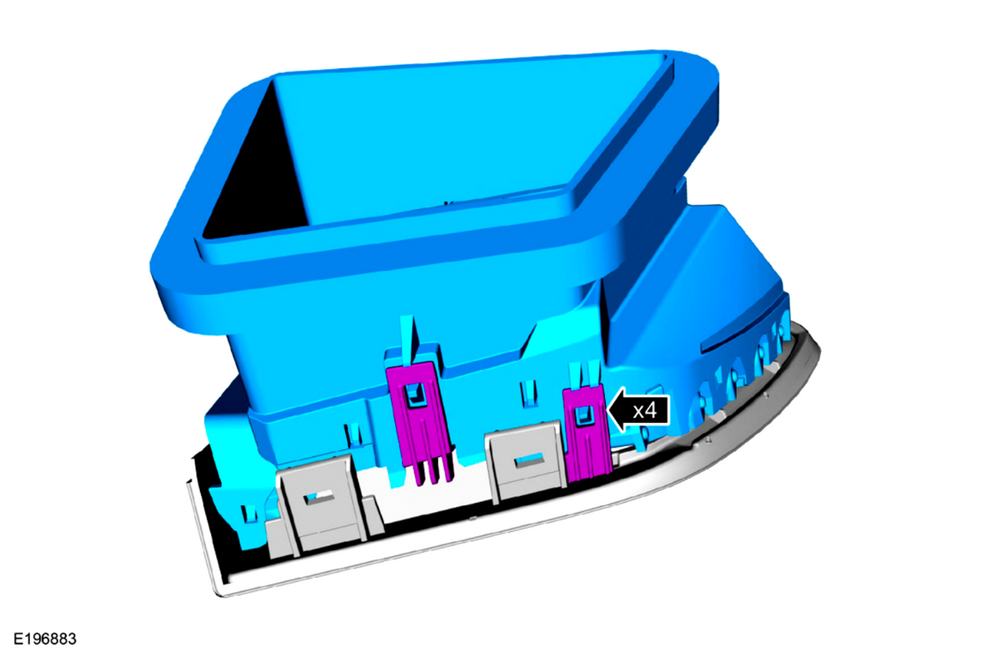

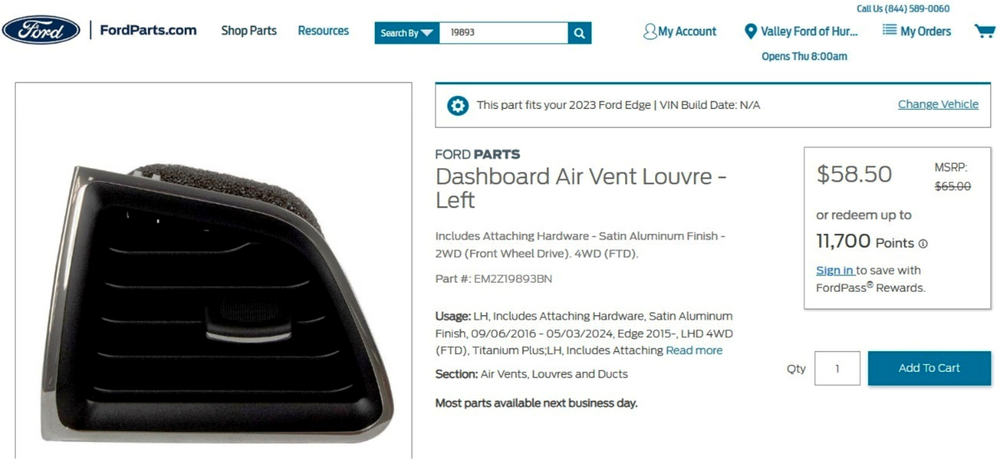

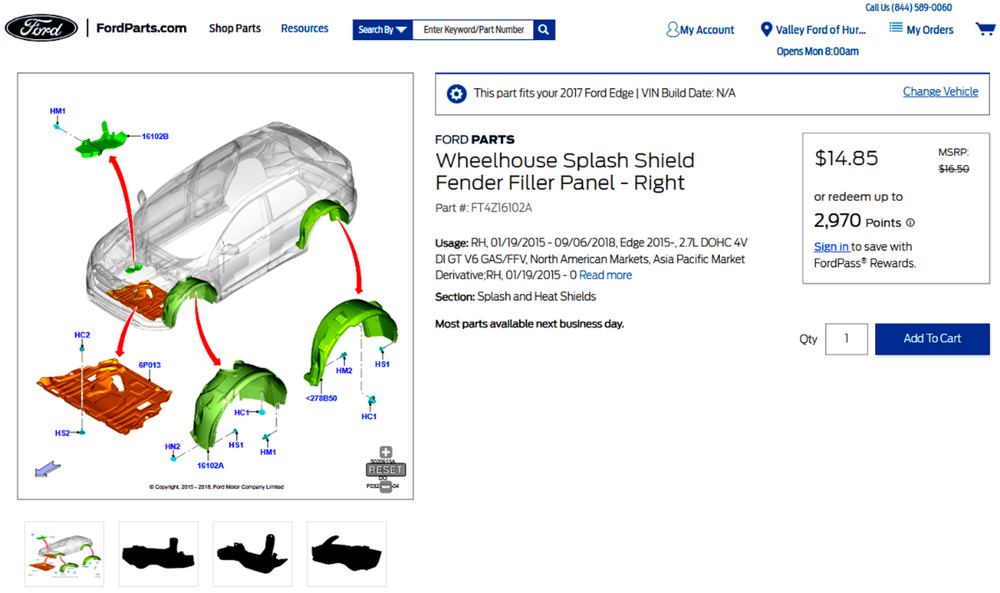

Welcome to the Forum @Jetboy47! The following is the Workshop Manual removal and installation procedure, which is also attached below as a PDF file... Driver Side Register Special Tool(s) / General Equipment Interior Trim Remover Removal Release the clips and remove the LH instrument panel finish panel. Use the General Equipment: Interior Trim Remover Release the clips and remove the driver side register assembly. Installation To install, reverse the removal procedure. Ford's online parts-selling site provides photos showing fuller detail of the retaining clips... Link to this FordParts webpage Good luck! Driver Side Register - Removal and Installation - 2022-2024 Edge Workshop Manual.pdf4 points

-

I did the larger rotor swap a few months ago. The brackets were readily available on Rock Auto to use the standard non ST calipers. I felt that the ST calipers would be too much change for a vehicle that has Adaptive Cruise with Stop and Go. The master cylinder even for the AWD rotors versus FWD is different, a lot more things are different for the ST and ST PP brakes. I also didn't go with drilled/slotted since this is both our daily driver and our vacation vehicle. I have around 6,000 miles on the new brakes and all is wearing well, all advanced braking things like stop and go adaptive cruise, ABS, etc work, and they have been hammered on and no fade in the mountains as before. Make sure you have a large enough spare for the front, or know you will be putting the spare on the rear if you get a flat in the front. I found a relatively cheap 18 inch spare from an MKX.4 points

-

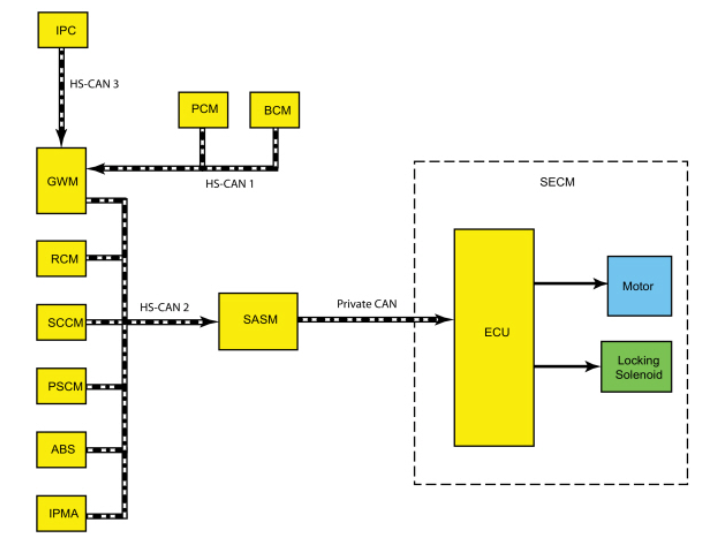

The closed-spoke steering wheels contain the motor for Adaptive Steering, as described in the 2019 Edge Workshop Manual... Adaptive Steering - Overview The adaptive steering system provides steering assist to the driver by dynamically changing the steering ratio between the steering wheel and the road wheels, thereby reducing the number of steering wheel turns required to turn the road wheels. This is accomplished through the use of a motor, worm gear and toothed hub. All adaptive steering system components are inside the steering wheel, behind the driver air bag. Additional technical detail on Adaptive Steering, from the Workshop Manual... Placing your device cursor over underlined acronyms may yield full-words descriptions of the acronyms. Adaptive Steering - System Operation and Component Description System Operation System Diagram Network Input Message Chart SECM Network Input Messages Broadcast Message Originating Module Message Purpose ABS active ABS module Used to inform the SECM an ABS event is taking place. Active front steering request ABS module Used to request steering angle changes for stability control events. EPAS fail PSCM Used to inform the SECM of an EPAS or PSCM failure. Lane keeping system status IPMA Informs the SECM of the current lane keeping system status. Odometer master value IPC This message is sent to the GWM and then to the SECM . Provides the SECM with the current odometer value in kilometers. Power pack status PCM This message is sent to the GWM and then to the SECM . Used to inform the SECM of powertrain status; OFF-torque not available, ON-torque not available, Start in Progress-torque not available, ON-torque available. Restraint impact event status RCM Informs the SECM of airbag deployment and fuel system cutoff due to a vehicle impact event. Stability control event in progress ABS module Used to inform the SECM a stability control event is taking place. Steering wheel angle ABS module Provides the SECM with steering wheel angle information for clear vision compensation. Steering wheel heat request IPC This message is sent to the GWM and then to the SECM . Informs the SECM the driver has requested the heated steering wheel to be activated. Transport mode BCM This message is sent to the GWM and then to the SECM . Used to confirm the vehicle is in normal operation mode, factory mode or transport mode. Turn signal status SCCM Informs the SECM of the current turn signal status; LEFT, RIGHT or OFF. Vehicle braking command ABS module Used to inform the SECM of vehicle braking. Vehicle configuration information BCM This message is sent to the GWM and then to the SECM . Provides the SECM with the current vehicle configuration (central car configuration). Vehicle speed PCM This message is sent to the GWM and then to the SECM . Used to inform the SECM of the current vehicle speed. Vehicle yaw data ABS module Provides the SECM with vehicle yaw data for clear vision compensation. Adaptive Steering System The SECM controls the functions of the adaptive steering system and communicates with other modules through the SASM over the HS-CAN2 . The SECM and the SASM communicate over a private CAN . To activate, the SECM requires battery voltage, ignition voltage and must communicate with other modules over the HS-CAN2 . The SECM must also receive the power pack status message from the PCM in order to activate. The SECM uses a motor to turn a toothed hub connected to the steering shaft to add or subtract incremental turns to the driver steering shaft input. At low speeds the same steering input from the driver delivers more front wheel angle, providing more low-speed agility. Low speed maneuvers require significantly less steering wheel rotation. At high speeds, straight line driving precision is increased, providing the driver with an improved highway driving experience and feel during moderate-to-high-speed cornering. As the driver turns the steering wheel, the SASM detects the speed and direction of the steering wheel rotation and transmits this information to the SECM over a private CAN . The SECM responds by activating the motor in the appropriate direction and speed to assist in turning the front wheels and reducing the necessary number of steering wheel turns required by the driver. The SECM is self-monitoring and is capable of setting and storing Diagnostic Trouble Codes (DTCs). Depending on the nature of the DTC , the SECM may engage the adaptive steering lock and may send a request to the IPC to illuminate the adaptive steering system warning indicator and display a message in the message center alerting the driver of a potential adaptive steering system concern. The warning message is sent over the HS-CAN2 to the GWM where it is converted to a HS-CAN3 message and forwarded on to the IPC over the HS-CAN3 . Adaptive Steering Lock The adaptive steering system is designed with a locking device. While the lock is engaged, the steering system is set to a fixed (1:1) steering ratio. A sound may be heard when the vehicle is started or shut off as the lock is disengaged or engaged and a slight movement of the steering wheel may be noticed while the locking action is taking place. If the vehicle loses electrical power or the SECM detects a fault while driving, the lock is engaged. Extreme operating conditions may also cause the SECM to engage the lock. This strategy prevents overheating and permanent damage to the adaptive steering system. Typical steering and driving maneuvers allow the system to cool and return to normal operation. While the lock is engaged, it is possible the steering wheel may not be straight when the vehicle is driving straight ahead and the driver may notice the steering wheel angle or "clear vision" may be off-set. The locking solenoid also engages when the ignition is set to ON and the driver door is closed, this prevents the steering wheel from turning unnecessarily while the system is off and affecting steering wheel clear vision. The locking solenoid disengages once the engine is started. Heated Steering Wheel The SECM is also the controlling ECU for the heated steering wheel system. For additional information on heated steering wheel functionality, Refer to: Steering Wheel and Column Electrical Components - System Operation and Component Description (211-05 Steering Wheel and Column Electrical Components, Description and Operation). Component Description Adaptive Steering Locking Solenoid The locking solenoid is a normally engaged (locked) solenoid which requires a voltage input to disengage (unlock). This provides a fail-safe in case of SECM or adaptive steering system failure. Adaptive Steering Motor The adaptive steering motor is a reversible, variable speed motor with an attached worm gear. The motor is internal to the steering wheel and is serviced with the steering wheel. SECM The SECM is the ECU for the adaptive steering system. The module monitors all sensor inputs and HS-CAN2 messages relating to the adaptive steering system and directly controls the output of the adaptive steering motor. The SECM is internal to the steering wheel and is serviced with the steering wheel. Conventional Edge steering wheel... Good luck!4 points

-

And i bought it-a white SEL with a few options-cold weather package/trailer towing package/activex seats. Guess it will have to do-replacing a 2019 SEL with same options but with Nav and convenience package.4 points

-

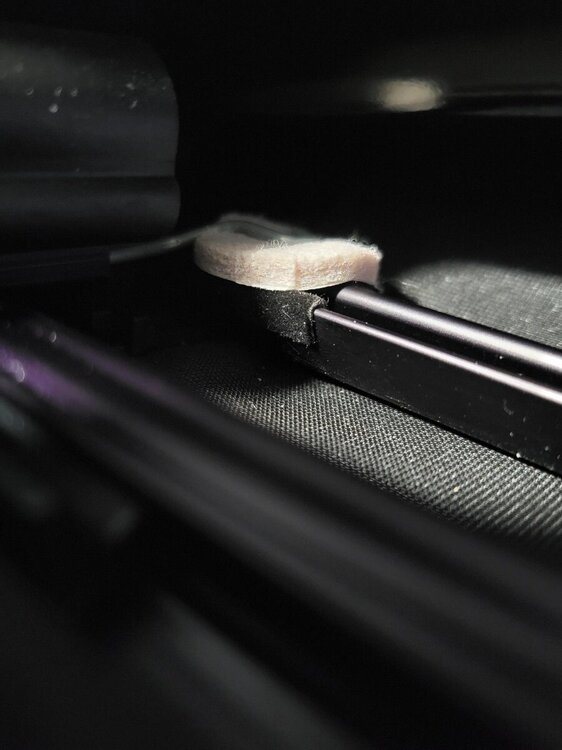

I think I found an easier solution to this issue. I was able to slide a screw driver under the clip and rotate it a little to lift it up. I then slid a thick piece of felt under the end of the clip and dropped it back down. I purchased a pack of those round stick-on felt pads that go on the bottom of kitchen chair legs from the Dollar Tree. The one I used was the size of a nickel. The very annoying tick is completely gone!!!!:) I had to redo this felt pad solution because it eventually compressed too much and the rattle came back. I ended up using a round piece of plastic about the size and thickness of a nickel with felt stuck to both sides. Just sticking felt to both sides of an actual nickel would also work well.4 points

-

4 points

-

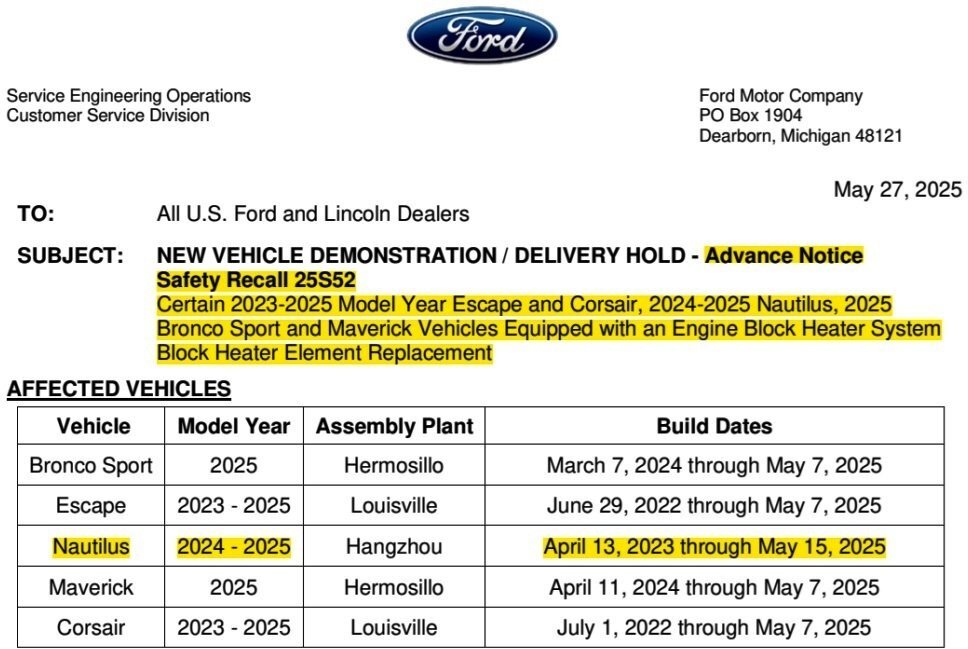

SSM 53601 2020-2023 Explorer/Aviator, 2020-2025 Police Interceptor Utility, 2020-2025 Escape/Corsair, 2022-2025 Maverick, 2024-2025 Nautilus - Hybrid - Illuminated MIL With DTC P2450:00 Stored In The PCM Some 2020-2023 Explorer/Aviator, 2020-2025 Police Interceptor Utility, 2020-2025 Escape/Corsair, 2022-2025 Maverick, and 2024-2025 Nautilus vehicles equipped with a hybrid powertrain may exhibit an illuminated malfunction indicator lamp (MIL) with diagnostic trouble code (DTC) P2450:00 stored in the powertrain control module (PCM). This may be due to an evaporative emission system concern or may also be caused by the customer overfilling the fuel tank. If this condition occurs, perform normal diagnosis per Workshop Manual (WSM) Section, 303-13 and repair as necessary. Inform the customer that the condition may have been caused by overfilling of the fuel tank and to not top-off the fuel tank when the fuel pump nozzle automatically shuts off for the first time. Refer the customer to the Fuel and Refueling section of their Owner Manual for additional information.4 points

-

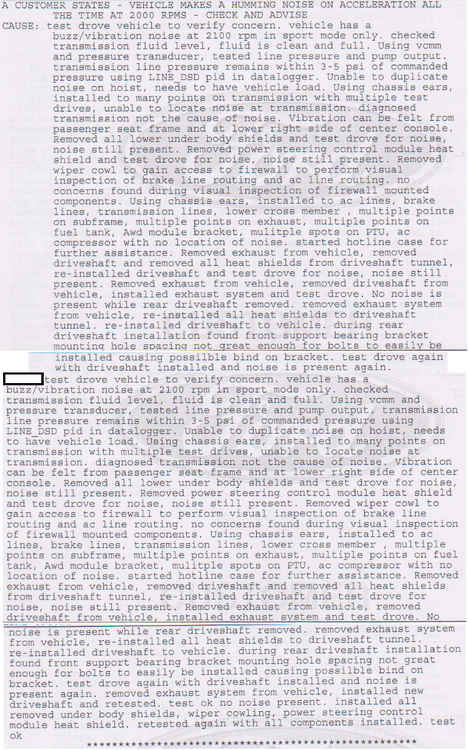

Back again after a different dealership having my Edge for just about a month. I THINK we have figured out the problem. I will paste the (quite long) write-up from the master mechanic - as it would be more helpful than anything I would try to explain. Hopefully it helps at least ONE person that may be experiencing a similar problem. 2020 Ford Edge ST with 17k miles on it, 100 visits to dealerships, ridiculous amounts of time without the car, $1000's wasted, "fixes" that ended up not being fixes, etc. The master mechanic found it to be the driveshaft installed improperly from the factory. Please read the write-up for more details. I appreciate all the messages with guesses at what this could be. After getting a new transmission and it essentially being a placebo-fix where we weren't hearing the noise for a short period, here is to hoping that this new, properly installed driveshaft resolves this FIVE YEAR problem we've been experiencing. Thanks again!4 points

-

4 points

-

4 points

-

Hi all, I was able to complete the repair successfully! It wasn't the hardest repair I have ever done, but it also wasn't the easiest. If you take a plastic trim removal piece, the little white clips are very easy to pop off. The problem I faced when doing this repair was, as the manual stated, some come with little dollops of polyurethane in the corners, and my car was one of the ones that had this. It is a very tight spot to get a razor blade in there. I am, unfortunately, at college, so I have very limited access to tools, but I would recommend a spackle knife to get in there and to pull that polyurethane out. This is a very tedious process and takes a good amount of time. Once that was finished, the whole trim piece popped off, allowing me to access the underside to install all of the clips. I got new clips from a Ford dealership, and I noticed a little upgrade was made to them. There is a little white piece that applies pressure to ensure that the clips don't fall out, like how mine fell out. You can notice the difference in the picture below. Once the clips were installed, some of the weather stripping came undone so I purchased new weather stripping at Home Depot and installed it. To reinstall the trim piece, you can simply line up the holes with the clips you installed on the trim piece and then apply some pressure; you will hear loud clicks for every clip you have. You must insert the clips into the trim piece, you can't put the clips onto the frame of the car. During this whole process, I got a little impatient undoing the polyurethane and snapped the trim piece in 2 places. I was able to silicone the pieces back together, it's not very noticeable, but I would recommend taking your time to not let this happen to you. Down below I have numerous photos of the whole process, let me know if anyone needs help. Again, thank you everyone for your help, you made this process a whole lot better for me! B7707F98-D065-4C9B-9911-2698517FCE65_1_201_a.heic4 points

-

I have finally solved the issue of the rear seat belt extenders for my 2020 Ford Edge Titanium. We have child booster seats for our two granddaughters and it was very difficult to secure the seatbelts because of how low the receptacles are set in the rear seat. With the 60/40 split fold down rear seat, there are two completely different seat belt connectors. One for the seat on the passenger side and one for the seat in the middle and driver's side. The seat on the passenger side has a unique buckle arrangement and requires the following extender (KT4Z-78611C22-AA). The seat on the drivers side (and middle seat) has a normal buckle and uses the following extender (6L2Z-78611C22-AA). Once I got both of these and made sure they worked, I tried to explain this to the parts person at the local Ford dealership. They were uninterested. Please note that both of these are available free of charge from Ford, although they may have to be ordered. The passenger side extender is the more difficult one to obtain.4 points

-

Good luck! 360 Camera - Wiring Diagram 2 - 2024 Edge - China.pdf 360 Camera - Wiring Diagram 1 - 2024 Edge - China.pdf Parking Aid - Component Location - Description and Operation - 2024 Edge Workshop Manual - China.pdf Side Parking Aid Camera - Removal and Installation - 2024 Edge Workshop Manual - China.pdf4 points

-

Scammer. Stop Forum Spam dankalamaras98@gmail.com IP: 159.26.101.115 dankalamaras98@gmail.com - Google Search 2017 Ford Edge Sport 21" wheels - Edge Forum - Blue Oval Forums3 points

-

More and more of this AI slop garbage showing up on youtube lately. It is super easy to generate and the title alone to me says it is clickbait someone is generating to drive their revenue stream from the platform. When I run across these things I block youtube from suggesting the channel again, but it is a wackamole game sadly.3 points

-

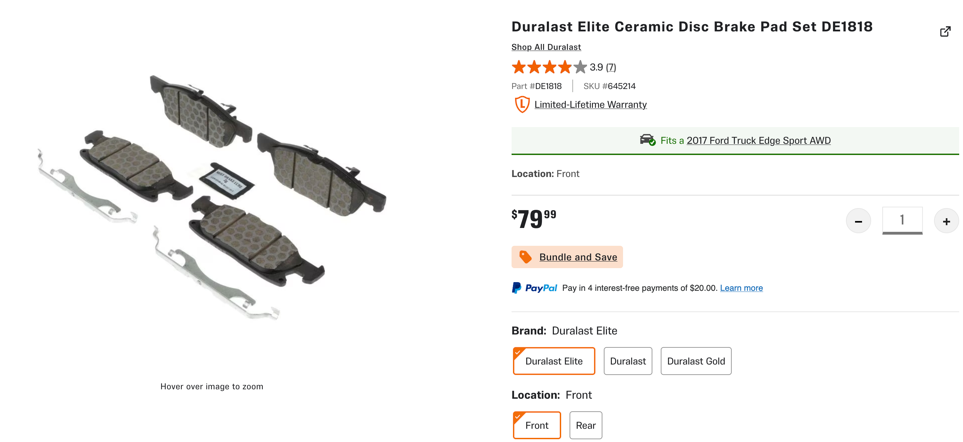

Today I installed the RH CV Axle. The only battle I had was extracting the axle - all YT videos show smacking the inner joint with a hammer - I even went to Lowes to get a heavier hammer, and that didn't work - see the section of all-thread and nut in the photos - I cut a length of all-thread to fit snugly between the inner joint and a bolt head on the PTU, then holding it with a pliers I backed the nut out and as it reached the end of its thread the axle was free to extract - way better than beating on it. The I noticed the friction material had come off the outboard brake pad - went to Autozone and got a set of new pads - found the same thing on the LH. The LH CV Axle cured the vibration but I could still just a little at exactly 60mph with acceleration - that is gone now. The inner joint on the RH axle had similar wear divots, just not as deep - the lubricant didn't run out like oil as was the case with the LH, but it looked an odd brown color.3 points

-

3 points

-

I would go with the H6 AGM Everstart Platinum from Walmart. Be sure to reset your battery monitoring and select a new battery code if you change size and type.3 points

-

I just did my RDU, PTU and a transmission drain and fill the past few days. I just passed the 20k mark on my 2023 ST. The RDU fluid was ok, but honestly it didn't need to go any longer. I put in a few more oz than I took out. The PTU on my vehicle has no drain plug and it is different than all the videos out there that I can find to do a drill and tap. With not being sure where to put a drain plug I pulled/sucked out 350ml and put in 500 ml. Again they shorted me on fluid. The PTU fluid looked good, I was really pleased to see that. I replaced 5 quarts of transmission fluid and it looked in really good shape. I was worried reading all the concerns with the RDU, PTU and transmission. As little as this all cost me in fluids, probably about $120 in total, I think it is worth doing every 20k or less as the RDU fluid definitely needed to be replaced, and only being able to get half the fluid in the PTU. I used the Motorcraft fluids for the RDU and PTU and used Valvoline ULV fluid for the transmission. I bought the Motorcraft fluids on Amazon and the transmission fluid on Rockauto.3 points

-

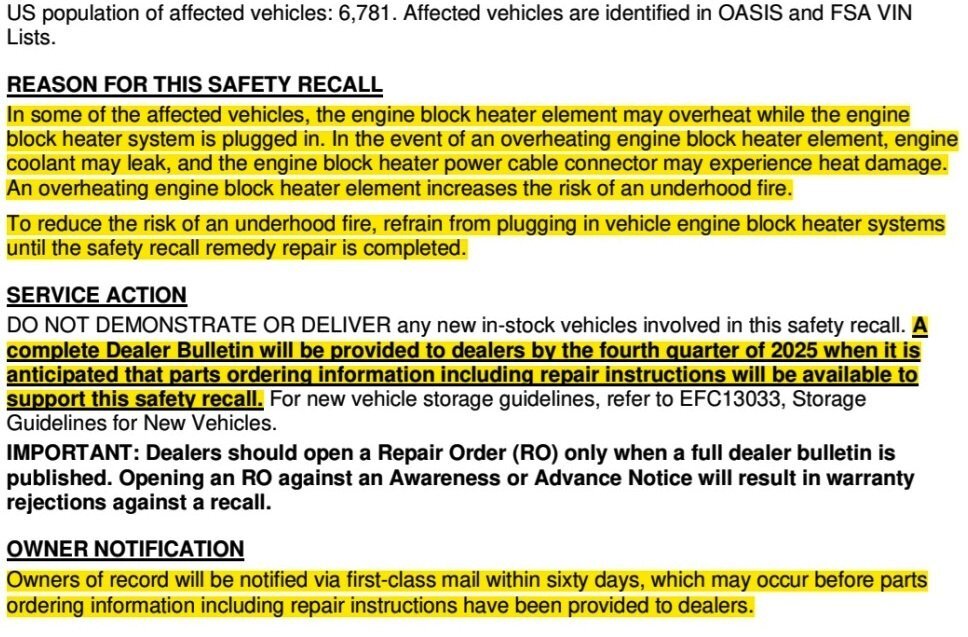

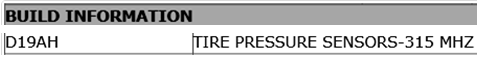

@m4rioo: Ford OASIS info for your Edge's VIN confirms 315 MHz... VIN-based TPMS sensor search from Ford's online parts-selling site... Radio frequency interference can negatively impact TPM systems, per the 2022-2024 Edge Workshop Manual, included below and more fully covered in the attached PDF documents... Placing your device cursor over underlined acronyms may yield popup full-words descriptions of the acronyms. Radio Frequency Interference (RFI) RFI can be caused by: Video equipment has been found to cause RFI especially when the video and power supply lines are near the TPMS . Anti-theft alarms (even those installed by the dealership) have been found to create enough RFI to cause the TPMS to malfunction or lose considerable range. These anti-theft alarms can be difficult to locate, as they are usually hidden somewhere out of the way for reduced accessibility. Many in-vehicle cell phone chargers have been found to cause considerable RFI . The vehicles with the power point closest to the RTM are the most affected. It must be noted that most cell phone chargers do not produce high levels of RFI all the time. This depends on the state of charge of the cell phone battery. The phone battery must be almost completely discharged in some cases. Power supplies and DC / AC inverters typically create a lot of RFI . Most consumer grade equipment has very little filtering or shielding. Using Hit Rate Parameter Identifiers (PIDs) to Determine the Presence of RFI If an intermittent RFI issue is suspected, the information contained in the last 5 TPMS warning event Parameter Identifiers (PIDs) can be combined with specific Parameter Identifiers (PIDs) from the BCM to determine which TPMS sensors are being affected and if a RFI source is currently present in the vehicle. The BCM module contains Parameter Identifiers (PIDs) used to keep track of the number of TPMS messages received from the 4 trained TPMS sensors. These Parameter Identifiers (PIDs) can provide insight on the performance of the TPMS , and can help establish the presence of an Frequency Interference (RFI) source. TPM_HITS_LF (Tire Pressure Monitor Hit Rate Left Front) – The number of TPMS messages received by the BCM module from the LH front sensor TPM_HITS_RF (Tire Pressure Monitor Hit Rate Right Front) – The number of TPMS messages received by the BCM module from the RH front sensor. TPM_HITS_LRO (Tire Pressure Monitor Hit Rate Left Rear Outer) – The number of TPMS messages received by the BCM module from the LH rear sensor TPM_HITS_RRO (Tire Pressure Monitor Hit Rate Right Rear Outer) – The number of TPMS messages received by the BCM module from the RH rear sensor. Method for determining if a RFI issue has been affecting the TPMS : Collect the last 5 TPMS events and determine if they were due to system faults or low tire air pressure. Collect the TPMS Hit Rate PID counters and compare them to the last 5 TPMS events. If the TPMS Hit Rate PID counters are significantly different from each other or if the locations with lower hit rate values show up as fault locations in last 5 TPMS events and BCM DTC B124D:02 (Tire Pressure Sensor: General Signal Failure) is present, an intermittent RFI source is most likely preventing the signals from these TPMS sensors from reaching the BCM . An intermittent RFI source can also be the case when all 4 TPMS sensors show up in the last 5 fault events and BCM DTC B1182:00 (Tire Pressure Monitoring System (TPMS): No Sub Type Information) is present. The possible cause would a strong source of RFI noise. Original Equipment Manufacturer (OEM) Modules In some cases the RFI may actually be caused by a module or ground on the vehicle. Depending on the severity of the concern, a dirty ground, improperly built ground shield or module can disable the system. Modules that have microcontrollers using clock circuits to create timing pulses for the microprocessor may radiate RFI . Using Customer Electronics to Pinpoint RFI This method can be a way to determine the cause of a concern before the sensors and module are replaced with little or no effect on system performance. Discuss with the customer what types of devices they were using when the event occurred. Determine which power points are being used and, if necessary, ask the devices be activated to determine their affect on the TPMS . Options for Eliminating Intermittent TPMS Operation Caused by RFI If an Original Equipment Manufacturer (OEM) component or customer device is causing a RFI concern, replace the device. If a phone charger is causing a RFI concern, the customer should consult with their cell phone provider to acquire a different battery charger. If a device such as a dealer installed anti-theft alarm is causing a RFI concern, move the device to another location in the vehicle. In the case of a portable device move the power cord to another power point location. In summary, if the RFI source is present and cannot be moved or replaced, the intermittent concern remains. The TPMS must accept the unwanted system operation the RFI can cause. Good luck! Tire Pressure Monitoring System (TPMS) - System Operation and Component Description - 2022-2024 Edge Workshop Manual.pdf Tire Pressure Monitoring System (TPMS) - Diagnosis and Testing - 2022-2024 Edge Workshop Manual.pdf3 points

-

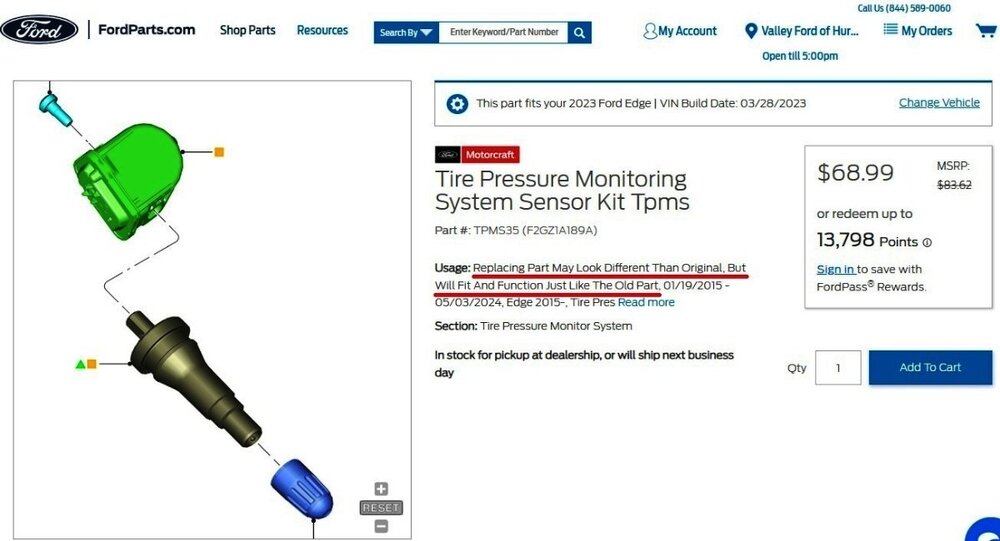

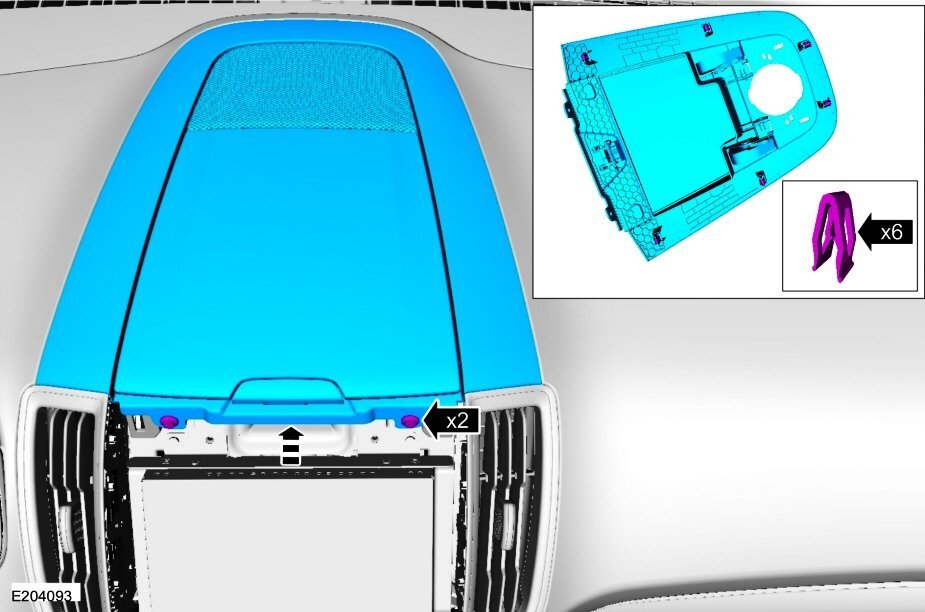

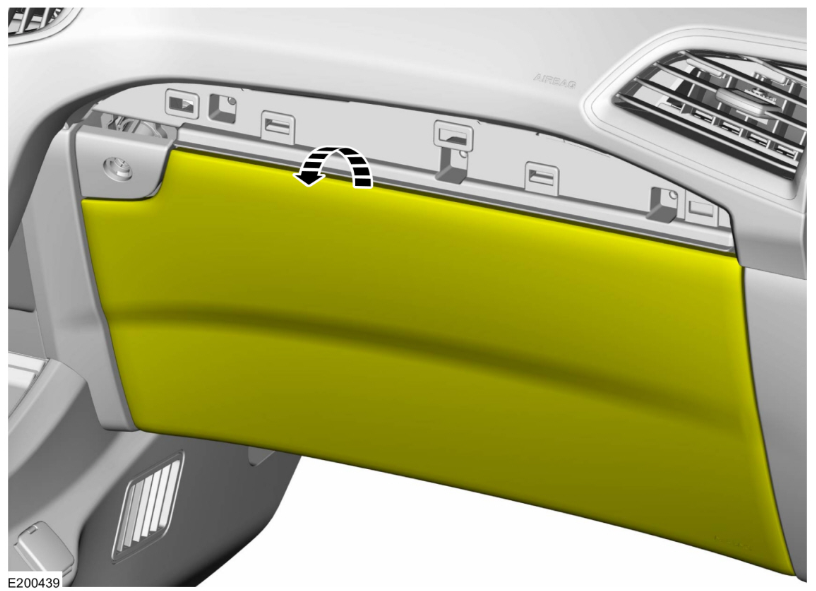

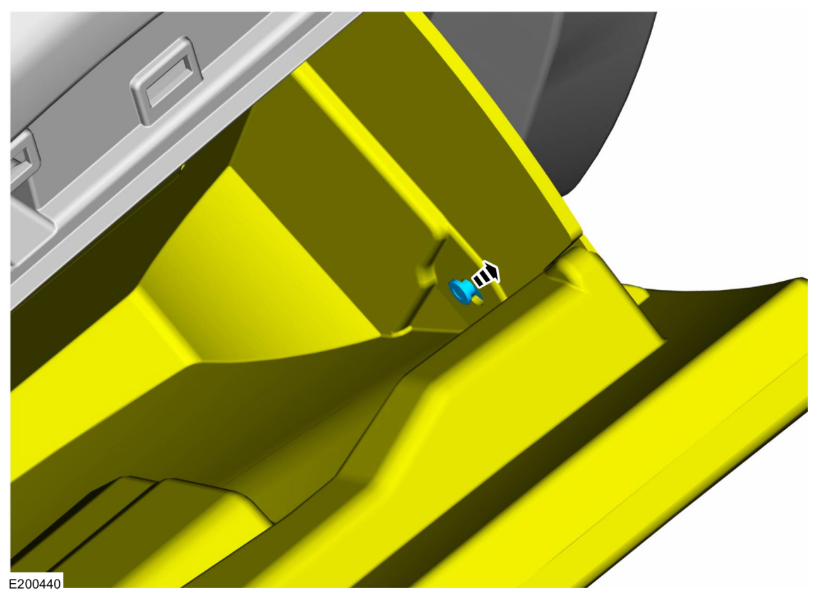

Welcome to the Forum, @giraffegeoff! Looking at your photo -- as you have no doubt already recognized -- there are clear visual differences between the red-arrowed side on which the unlatching button is sagging, and on the green-arrowed side where the unlatching button is not sagging... The plastic piece, pictured in your palm, likely broke away from the sagging-button-side, where it previously supported the button, and its rectangular stem passed through the red-arrowed voids to release the lid's latching mechanism. The button/latching mechanism is available only as Provided In Assembly (PIA), meaning that buying the entire storage compartment bin/lid assembly is required, if you wish to replace it. Ford's online parts-selling site offers several photos of the replacement part... Link to this FordParts webpage It's worth noting that the underside-view photo provides little detail of the button/latching mechanism, though it is possible an engineering improvement was made to the original mechanism design. The instrument panel storage bin lid assembly (FT4Z58301A05AA) is retained by two screws holding the audio speaker in place, and by two screws into the center stack... Accessing the two center-stack screws requires removing several adjacent components, as described in the two Workshop Manual sections that are attached below as PDF documents... Good luck! Front Controls Interface Module (FCIM) - Removal and Installation - 2016 Edge Workshop Manual.pdf Instrument Panel Upper Storage Bin Edit - Removal & Installation - 2016 Edge Workshop Manual.pdf3 points

-

9 years of driving mine. Only had to do maintenance. No broken parts. Runs like it did new. Still like everything about it. Been a great car.3 points

-

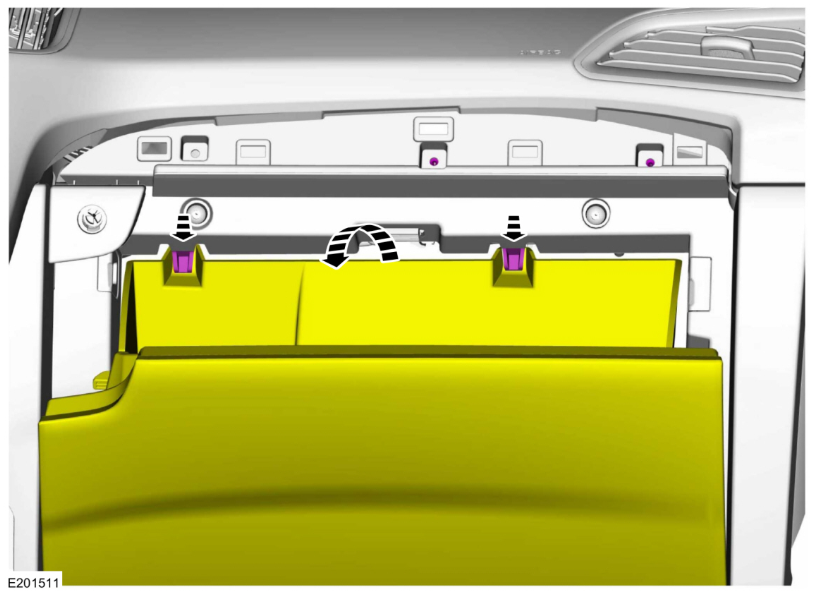

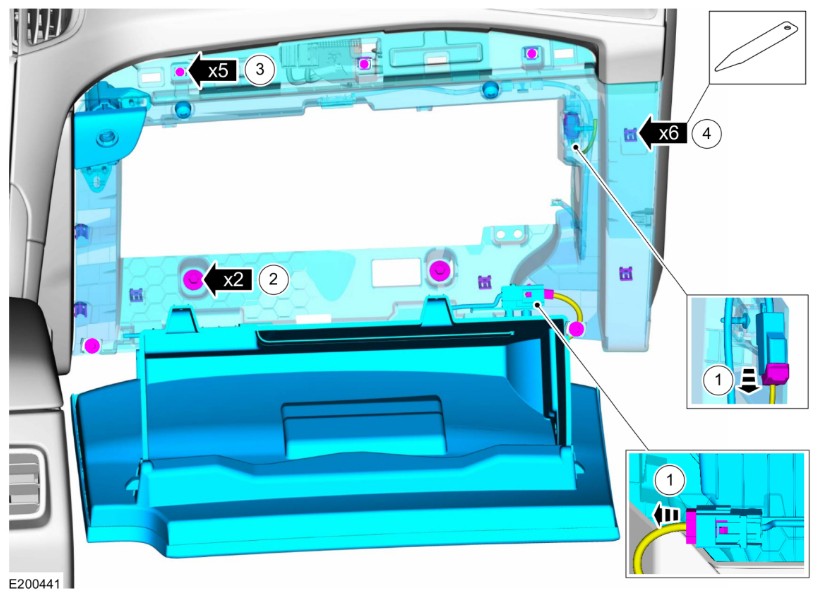

Welcome to the Forum @Milo M! To ensure your personal Health and Safety, because the Passenger Knee Bag is integral to the Glove Box assembly, please review and fulfill the Supplemental Restraint System depowering and repowering procedures... From the 2019 Edge Workshop Manual... WARNING: The following procedure prescribes critical repair steps required for correct restraint system operation during a crash. Follow all notes and steps carefully. Failure to follow step instructions may result in incorrect operation of the restraint system and increases the risk of serious personal injury or death in a crash. NOTE: Removal steps in this procedure may contain installation details. Depower the SRS . Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures)... (This procedure is also attached below as a PDF document) Removal Open the glove compartment. Detach the glove compartment door damper. Push the tabs and release the glove compartment door. 4 Disconnect the electrical connectors. Remove the bolts. Torque: 35 lb.in (4 Nm) Remove the screws. Torque: 22 lb.in (2.5 Nm) Release the clips and remove the glove compartment. Use the General Equipment: Interior Trim Remover (This procedure is also attached below as a PDF document) Good luck, and Work Safely! Supplemental Restraint System (SRS) Depowering - General Procedures - 2019 Edge Workshop Manual.pdf Supplemental Restraint System (SRS) Repowering - General Procedures - 2019 Edge Workshop Manual.pdf3 points

-

Job done. After a closer look I could tell that this was a botched installation by SafeLite when they installed the 3rd windshield. I placed painters tape over the areas above the 7 white plastic clips and started at the far left thumping the tape and hearing the clips engage. I'm confident that its secure now.3 points

-

Rafeek, I just noticed the same thing on my new 2024 Edge ST. and I too have temporarily secured it with cable ties. My St does have the tow package and could you give me any additional information on where to get this part. Thanks so much3 points

-

The new Livernois tune seems to shift pretty well. At least a lot better than stock.3 points

-

3 points

-

@bscott94 my Costco battery lasted about the length of the warranty and that's why I decided to go with the Everstart AGM. Edit: Gone are the days when Costco batteries were high quality with the best replacement warranty around.3 points

-

Do I need to remove the front bumper to replace the entire passenger side fog light assembly on a 2017 Ford Edge? Or how does one best replace the assembly? I removed the splash guard/ under carriage and still could not get to it. Thank you.3 points

-

Great news. I was able to replace the brake light. It was incredibly difficult to remove the top. Thank you all for all of your help. I ended up going to a mechanic3 points

-

I gave up on the Ford parts, both original and updated. I use TOGGLER TC wall anchors. I cut off enough of the vertical fins, that help grab drywall, to allow the toggle to go through a 3/8 inch fender washer. I hot glued 1" OD x 1/2" tall x 1/2" ID nylon spacers (McMaster #94639A876) to the inside of the covers. I inserted the toggler where the old Ford part was and then used the toggler tool to set the toggle. I did this two years ago and all are sill holding strong.3 points

-

Been a while since i posted the MkX. Since then it has become my daily driver as the Mercury is now gone. I drove it all winter, she started right up at -15F and I drove it through some pretty bad weather. It has even been used for some light choring and driven through the pasture. I am gaining a lot more confidence in it. Not sure I would drive to the coast but I would probably take it anywhere in Iowa at this point. I have put a bit over 6k miles on it. Gave it an oil change last weekend, it only used a pint in 6K miles so the motor seem pretty tight. Still some vibration and clanking but I am just living with it. It now has about 275,600 miles on it, averages about 20-21 MPG. Best part is that I have $658.60 into it (with the latest oil change, not counting fuel and insurance). Picked it up on August, it's now March so that is about $82/month. Once of the plastic radiator lines is starting to seep so I need a cheap fix for that. Still need to change the fluid in the PTU as well. At this point I am just going to run it until something major happens or it needs tires.3 points

-

2015-2018 Edge Workshop Manual - Rear Differential Unit (RDU) - Filler Plug ONLY 2019-2024 Edge Workshop Manual - Rear Drive Unit (RDU) - Filler Plug 2019-2024 Edge Workshop Manual - Rear Drive Unit (RDU) - Drain Plug 2007-2014 Edge Workshop Manual - Rear Differential Unit (RDU) - Filler Plug ONLY Good luck!3 points

Repowering-GeneralProcedures-2019EdgeWorkshopManual.thumb.jpg.9f065584f1c6f7e91e11ee548f927a78.jpg)

Depowering-GeneralProcedures-2019EdgeWorkshopManual.thumb.jpg.d3c4a5d95affb20f562f0beac109900e.jpg)

-FillerPlugONLY.thumb.jpg.909f0bcf4eef17868eb2a4ad32637852.jpg)