Leaderboard

Popular Content

Showing content with the highest reputation since 01/13/2026 in all areas

-

That press release looks to me like they planned to relabel they BG44K in the Ford branded package. I can vouch for the 44K stuff in the 2.7. Having used it, the stuff is legit.4 points

-

I believe your assumptions are incorrect. The IAT isn't sensitive to fouling. These days an MAP has taken the place of the MAF - the MAP is way less sensitive to fouling compared to the MAF and its very rare that it requires cleaning. My 2017 2.7L has 123K miles on it and its never needed carbon removal. .3 points

-

Scammer. Stop Forum Spam dankalamaras98@gmail.com IP: 159.26.101.115 dankalamaras98@gmail.com - Google Search 2017 Ford Edge Sport 21" wheels - Edge Forum - Blue Oval Forums3 points

-

3 points

-

As ignorant as I am, why is a transmission fluid change so complicated. An engine oil change is so easy compared to a transmission service.3 points

-

More and more of this AI slop garbage showing up on youtube lately. It is super easy to generate and the title alone to me says it is clickbait someone is generating to drive their revenue stream from the platform. When I run across these things I block youtube from suggesting the channel again, but it is a wackamole game sadly.3 points

-

That model year & trim did not come with a 2.7L V6. The SE trim only came with the 2.0L 4 cycl turbo. The 2.7L V6 was only offered in the ST version. Some Lincoln's may of had that engine available to it, but all models of Edge's, except the ST, got the 2.0L cylinder Ecoboost. As far as purchasing, all depends on maintenance price. I'd swap all fluids & check for brake & tire wear. Overall, those model years are good, but all depends on how well the vehicle was maintained.3 points

-

Introduction post. Just saying hi. Just got new to me '14 Edge SEL 3.5 AWD. Sync 2 v3.10 Has 180k on it now but was fleet vehicle 90%of it's previous life with all maintenance done. Just got forscan and enabled remote start and tried the navigation hack... Success with the remote start .. jury still out on the nav.2 points

-

I had EBC's on my focus years ago, geez 20 years ago at this point 🙃, & I wasn't too impressed with them. I found Centric when I did the SVT brake conversion & have been loyal ever since. When I converted back to stock before selling the focus, I missed a driveway entrance as I was so used to bigger brakes of the SVT conversion. I really miss that car sometimes, but it was never engineered to last through northern winters 😢2 points

-

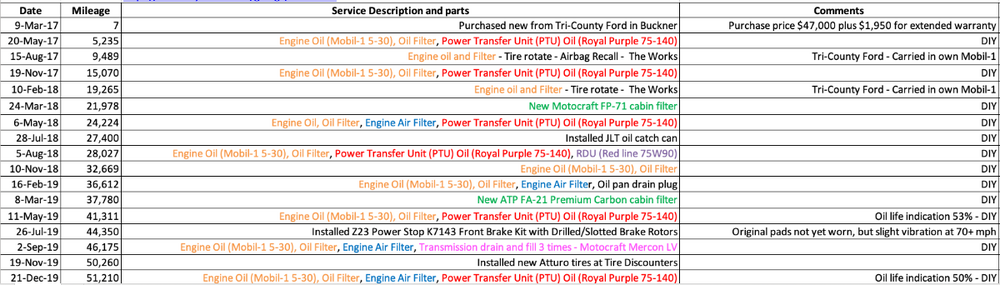

2020 2.7 EcoBoost (GEN 1) owner here. Just an introduction. Hoping to fit in with everyone here. Left TN in 1979 and landed in FL in 1999 after 20 years in the US Army. Headed to the Edge/MKX/Nautilus forum to post now. Feel free to head over to my first post to see what I did to my vehicle ... not much, but, it's a start on a journey for power.2 points

-

Has anyone installed this or something similar? Any thoughts on whether it is worth doing or not.... https://www.jxbperformance.com/products/p/ford-edge-2nd-gen-escape-3rd-gen-and-lincoln-nautilus-1st-gen-differential-bushing-insert-kit2 points

-

You can do the tranny at the same time! Pop 2 plugs, drain, add the fluid (Ford has built-in a handy funnel holder), drink your favorite waiting beverage for the fluid to reach 180 F about 10 minutes and install the site plug!2 points

-

I feel pretty confident doing my first PTU and RDU service. I'll probably take it to my dealer for the transmission service. More so, just concerned that they actually do it. And do it right! Being on this Forum gives me so much valuable information. Including a lot more confidence in doing some of my own maintenance. Thanks to everyone!2 points

-

2 points

-

2 points

-

Following a Google search it seems it was not a rumor, but an actual agreement. BG's press release announcement here. Attached is a Motorcraft leaflet. Parts can be found online, examples: PM-44-A here. PM-30-K here. Chemical_Product_Flyers.pdf2 points

-

Thanks Enigma. I was able to fix my parasitic draw issue, or at least it's gone for now. I remembered I was having problems with my ignition key switch a while back where the key was sticking and wouldn't turn easily. I decided to spray electronics cleaner into the key switch and worked the key in and out cleaning debris with a cloth. The parasitic draw stopped immediately. Similar to the tailgate connector corrosion causing the PCM to not go into sleep mode, the ignition key switch was doing the same. I'm symptom free for 5 days.2 points

-

Makes perfect sense. If they can charge you a ridiculous amount of money to do it at the dealership, as opposed to a 10 dollar bottle you can do yourself. I run a bottle of Chevron Complete fuel system cleaner with a full tank of gas about every 3-4 thousand miles.2 points

-

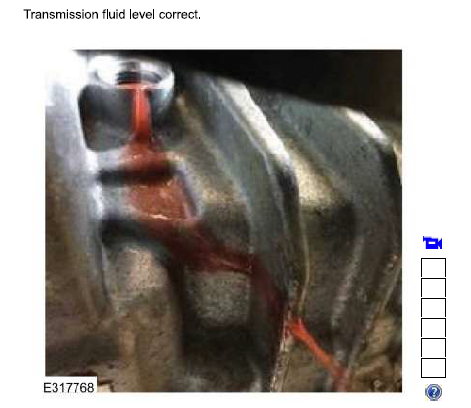

The section below that which has "Transmission Fluid Level Check" also tells you to add a liter after checking and installing back the level plug.2 points

-

I just got a notice from Ford that I could extend my Blue Advantage service plan. I least I think it was from Ford. I go to the web site and put in the reference number I got from them. It would not work, there was a problem. The message said I should join a Chat to resolve the issue. Of course they wanted my email address, for no good reason. When I got on line with the Chat lady I was told that she could not solve the issue and that I needed to talk to one of there sales reps. I wonder if this web site works at all or if it is designed to fail so I have to call one of their sales reps. A high pressure sales rep, I am sure. This is total BS and makes me want to buy anything but a Ford for my next car. When did flat out lying to your customers become standard business practice.2 points

-

Well, think about this: Take that $2400 / yearly cost and put it in a separate bank account and use that money for big repair bills. After a few years, that will be a tidy sum to dip into. If you never need it, then you have a bundle of cash for something else. If it was me, I would not pay that. Too much money.2 points

-

I think the 2022 FSM is a little more updated. The difference between the 5L and the 6L would be if the transmission was overhauled or if its just a drain/refill. If you added 6L at this step and the transmission was not overhauled I think its fine, there would just be more fluid draining out when you pull the leveling plug. Also if it was overhauled it still might be low when you pull the leveling plug so they have you add .25L at a time until it flows down the case correctly. From the 2022 FSM: 1. Transmission overhaul (includes main control and torque converter drain) Volume : 6.34 qt (6 L) 2. Main control overhaul or replace (with out transmission overhaul) Volume : 5.28 qt (5 L) So for the fill I put in 5L, got TFT up to 185 on jack stands, then pulled the leveling plug. The fluid looked like this: I let it drain right until it looked like this and then I installed the leveling plug: Then I buttoned everything back up and put in another 1L of fluid in as both the 2019 and 2022 FSM say to do. If you did not add that 1L, yours is underfilled. I put about 5K miles on the car since this flush and it shifts great. No weird shifts on the highway, no hunting for gears. It changes gears as it should. I also have Livernois updated tune but the tranny feels pretty good.2 points

-

Sounds like just another scam. I would regularly get notices that my extended warranty was going to expire and I needed to contact the warranty company. These notices were not from Ford, although they made it look like they were from Ford, but some 3rd party either trying to run a scam or trying to get me to buy warranty coverage I did not need. Simply go on-line to your Ford account and check your warranty and check your warranty paperwork you got when you purchased the vehicle.2 points

-

2 points

-

2 points

-

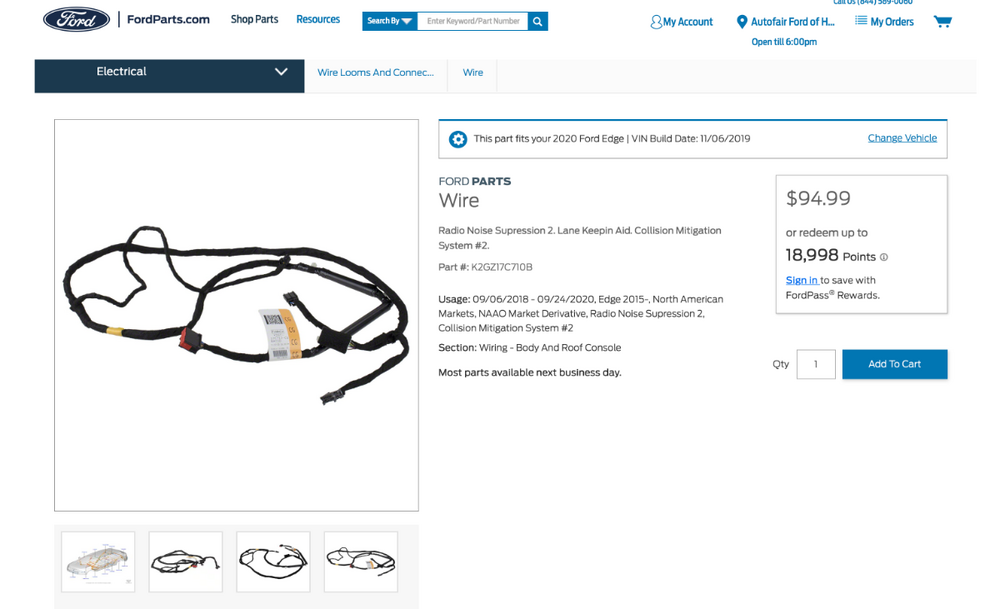

I have had the exact same messages however when this happened, I lost power steering completely. Not easy to steer this cars under manual power! I determined after research that the problem was with this part You could have the same issue. In my case, this cable had come loose and fallen down on top of my driveshaft, which burned through the cable, requiring full cable replacement. Maybe your connections on this cabe are coming loose? Maybe your cable has fallen down like mine did, just that it has not burned through? Maybe it is something different entirely. You can find this cable behind the motor. You have to look up between the back of the motor and the front of the transmission, above the driveshaft. This is a known issue by Ford, documented in Ford paperwork. It is covered under warranty.2 points

-

Hi BoostedEdge Thanks for sharing those FSMs. I have also done this procedure on my 2019 ST, and referred to the SM's you posted. The only procedure I did differently from the steps you posted is that I didn't top up the transmission fluid with 1L after filling with 6L then checking the level plug after reaching operating temperature since it seems that step is reserved for Initial Fills or for Transmissions that have been Overhauled. I didn't have mine overhauled or serviced, so I just did a simple drain/fill, filled with approx 6L, ran until operating temps were reached and checked the level through the level plug. In the attached references, it reads: 2022 ST FSM For Draining and Filling - Step 2. NOTICE: The following fluid amounts listed below are for initial fill only. 2019 Edge Transmission FSM - Filling Step 3. NOTE: Steps 3-8 apply if the transmission was overhauled. Did you have your transmission overhauled or a new one installed? I may be wrong so wanted to reach out. I monitored my temps on a long drive (2hrs) through some hilly terrain, max temps were 87C (188f), which seems to be similar to what you show here, so likely no overheating on either of our cases. But from what I understand, you don't want to overfill transmission units, nor do you want to be under by a liter.2 points

-

You need to make the harness from under the left head light to the center of the bumper. 4 wires. positive, negative, Can+ and Can-. The two CAN wires should be twisted. 18 or 20 gauge for the power is more then enough. If I had to do it again I would use a Cat5 wire. Use one of the pairs for the CAN. I would use a twisted pair for each power wire. For example: Blue Can+ Blue/White Can- Orange and Orange/White Positive Brown and Brown/White Negative This is an easy, but time consuming job, if you have experience with electrical work and basic mechanical skills. However, this is not a beginner project. You can do a lot of damage to the front bumper and wiring harness if you are not careful.2 points

-

yes they are full LED which is why I was looking at replacing the whole unit. They are not serviceable. it also started working again so idk wtf to make of it.2 points

-

2 points

-

Finally got to this project today. As previously stated, the splash shield is not sold separately. It is sold as part of the front fender liner. There are 3 plastic rivets attaching the shield to the liner, as well as two 9/32" bolts underneath. For easier access I also removed 2 plastic push pins and two 7/32" bolts attaching the liner to the fender. Used a pair of snips to break and remove the 3 plastic rivets inside the liner. Went to Lowe's and bought a black plastic bathroom garbage pail for around $8 that appeared to be the same thickness and material as the splash shield and was almost the same curvature/radius. Cut the pail in half the long way, flattened it out and traced the outline of the OEM splash shield on the garbage pail and used a dremel to cut it out. Smoothed all the edges and used about 10 aluminum pop rivets with small washers on the back side to attach the new plastic to the OEM shield. Used a heat gun to sort of melt part of the plastic to conform to a couple of curves in the OEM shield. Bought a Pittsburgh 7" Poly hand riveter kit for $12 at Harbor Freight, which came with an assortment of plastic rivets. Used that to re-attach the assembly to the fender liner. All in all about an hour's work, spent around $20 and its better than new, twice as thick as the original and looks fine. I even spray painted the aluminum rivets black, just because. And no need to remove the wheel/tire. With the steering wheel tuned full left there was plenty of easy access. Done and done!2 points

-

Mine do not have a spot for a replacement bulb, it is all integrated as one unit. Couldn't I reuse the light control module?2 points

-

The coolant intrusion issue was supposedly fixed for the 2019 model year for the Edge. I think most of the issues with the transmission are related to the 6F35 (harsh shifting, flex plate breaking) which was last used in 2018 in the Edge. While the 2019+ engine does have some new things (the EGR cooler), the 8 speed transmission has been around since 2019 (in the Edge, since 2017 in some other vehicles) and I haven't seen any trends of high failure rates or issues. I personally bought a 2019 at the end of its powertain warranty and felt good not opting for the extended warranty that was over 10% of the purchase price. It already suffered the EGR cooler failure, the PCM update done and the cooler replaced.2 points

-

I'm not normally a dealership guy, but I went there for the fluids. I almost fainted at the price of RDU oil, but it didn't take much. Tips: the RDU is rubber mounted, you can pry it slightly to get acess to the fill plug. The PTU is pretty easy. Just a bit of automotive yoga to get to the fill plug.1 point

-

Good callout on the stop/start accumulator. The solenoid on mine wasn't loose, but the seals on the solenoid pooped the bed and puked fluid in my driveway. Easy to replace yourself.1 point

-

1 point

-

Even though I hate it and will never use it, I do like having the ability to turn it on or off. \ Part of my start up process is push the start button, push the brake release button and disable the ASS 🤣.1 point

-

@IWRBB - sorry mate for not answering! I have no notifications. So those pictures/info come from factory service manual i bought when i bought my car. Manual has been built based on my car's VIN. However i found more versions are covered (including 2.0 liter engine and 8F35 tranny). Yes, you're right - essential if you want to do anything around your car.1 point

-

@Jetboy47 - could you share code address in ForScan you used to disable that bloody start-stop BS? I have ST 2022 and looking to get rid of SS as hell. No, i'm not going to use "elimintaor". Partially because importing it to europe will add even more $ to already ever priced gadget IMHO. Thanks!1 point

-

Hey guys, I don't know if this was mentioned earlier or even if this thread is still looked at, but is the CCM harness prewired? I've got a Titanium that I plan to retrofit ACC but I am still trying to figure out how difficult it would be and what parts I need.(Most of which I have gathered in this thread)1 point

-

Yes, they are not serviceable, you have to replace the whole thing! Expensive and sad. I think you should check all the plugs/connectors and grounds. unplug and plug back in. That will 'clean' the contacts. You might get lucky.1 point

-

Sounds like a good repair…..but not seeing the pic of the ball placement for this fix…….appreciate if you could repost pic or message me directly……Thanks1 point

-

1 point

-

1 point

-

1 point

-

Yes. The license plate was the source of mine too. I also noticed (new noise) that the trim pieces on the roof, both sides, just above windshield can make flappy/tappy noises at highway speeds and when I physically tap on them by hand, it replicates the noise.1 point

-

Get a different engine. There are no cam bearings as the cams run on aluminum of the head. So, if the engine is locked due to lubrication problems, the heads are smoked too.1 point

-

I was able to disable the Auto Start/Stop with the Forscan on my 2023 ST. It had a separate line in the easier worded section just for it labeled something like BSM / Auto Start Stop. There were other BSM items that you could modify so I believe it was just doing that and not disabling the entire BSM module.1 point

-

I just took delivery on a new 2024 Edge Titanium (301A package) with SYNC 4A. As far as I can tell, there is no Brake Hold option available in any of the vehicle settings. Also, there is not a button on the console to activate it. I called Ford support, they were no help at all. The owners manual contains the instructions on using it, but it does not correspond to what is available on the touchscreen.1 point

-

We found the issue in our car and fixed it. It was in fact the bar…kinda. The bar in question (runs along the width of the car in the rear of the vista roof, sits between the glass and the sunshade fabric), at least in my car, has a weird metal clip where it terminates on the right side. Applying pressure to that metal clip with my finger while my wife drove eliminated the noise completely. The clicking and rattling seems to be that metal piece shaking loose and springing against the bar. We fixed it for three dollars (and some careful work by my wife working in the very tight space between the glass and the headliner) by wrapping a cable management tie really tight around the bar and clip. Have driven 20+ miles and the noise is completely eliminated. i am attaching pictures of the clip, the ties we used, and the final product (had to use my phone camera to get a visual because of how tight the space is above the headliner). I would NOT use a plastic zip tie as the tie itself will rub against the sunshade fabric and you dont want it to tear. I like the ties in the picture because the soft side of the velcro is what touches the sunshade fabric. it took my wife (who is awesome) a few tries given how tight the space is…wasnt easy but the final product worked wonders. I imagine quiet tape would work similarly. hope this helps - considering there is soft tape under the clip before we made our repair it seems someone realized this is an issue at some point.1 point